Construction method of prestressed tubular pile

A technology of prestressed pipe piles and construction methods, which can be applied in the direction of sheet pile walls, foundation structure engineering, construction, etc., and can solve the problem of low bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

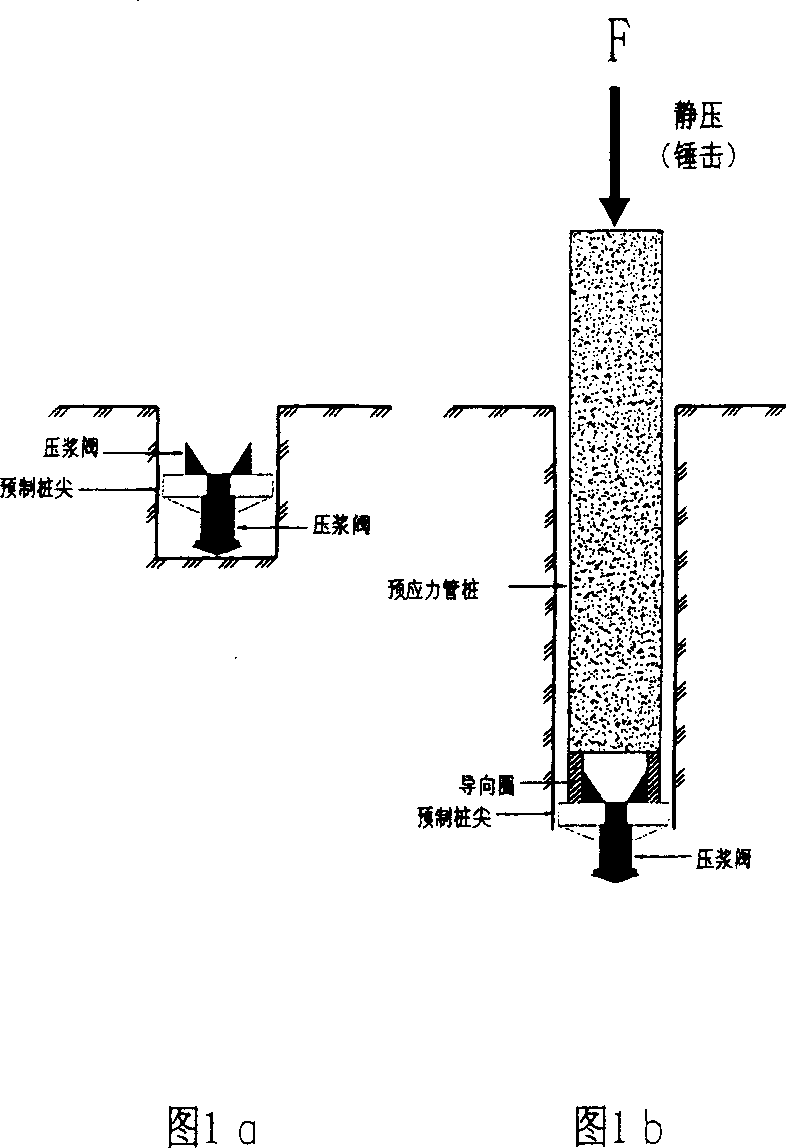

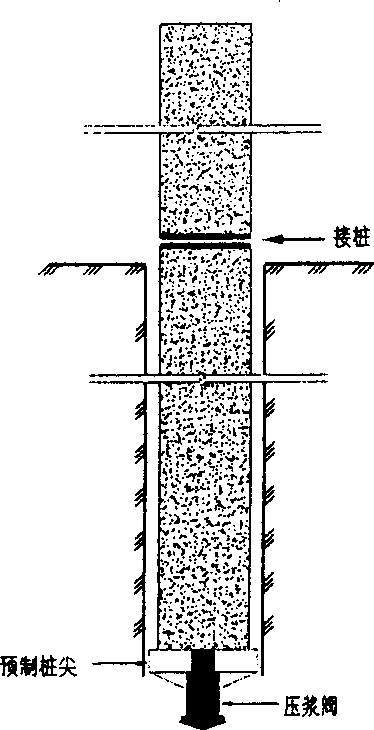

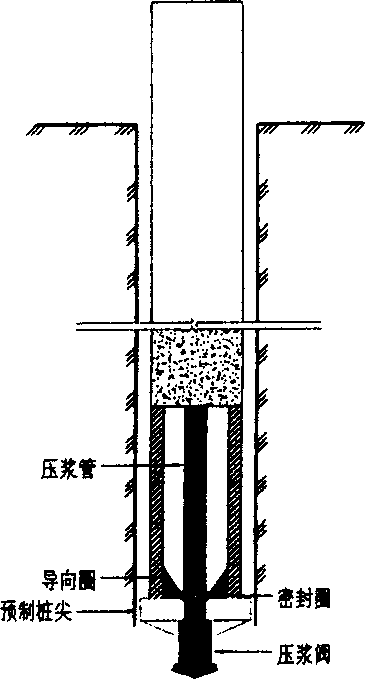

[0024] The construction method of the prestressed pipe pile as an embodiment of the present invention includes the following steps. First, as shown in Figure 1a, at the predetermined pile position, bury the prefabricated pile tip with the grouting valve and the guide ring Then, as shown in Figure 1b, the first prestressed pipe pile is connected to the prefabricated pile tip, and the prestressed pipe pile is pressed down to a certain depth in the soil by static pressure (or hammering). ; then, if Figure 1c As shown, the second prestressed pipe pile is overlapped on the upper end of the first prestressed pipe pile, and the second prestressed pipe pile is pressed down (or hammered). Repeat the above operations of lapping the pile body and pressing the pile until the pile end reaches the design elevation; after that, if Figure 1d As shown, the pressure grout pipe in the middle hole of the prestressed pipe pile is connected with the pressure grout valve; then, as Figure 1e As ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com