A rotatable multi-layer energy-absorbing dock fender

A dock fender and fender technology, applied in the field of ships, can solve the problems of large friction between the fender and the hull, reduce the service life of the fender, and have limited energy absorption capacity, so as to improve the vertical load resistance, reduce friction damage, The effect of increasing impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings.

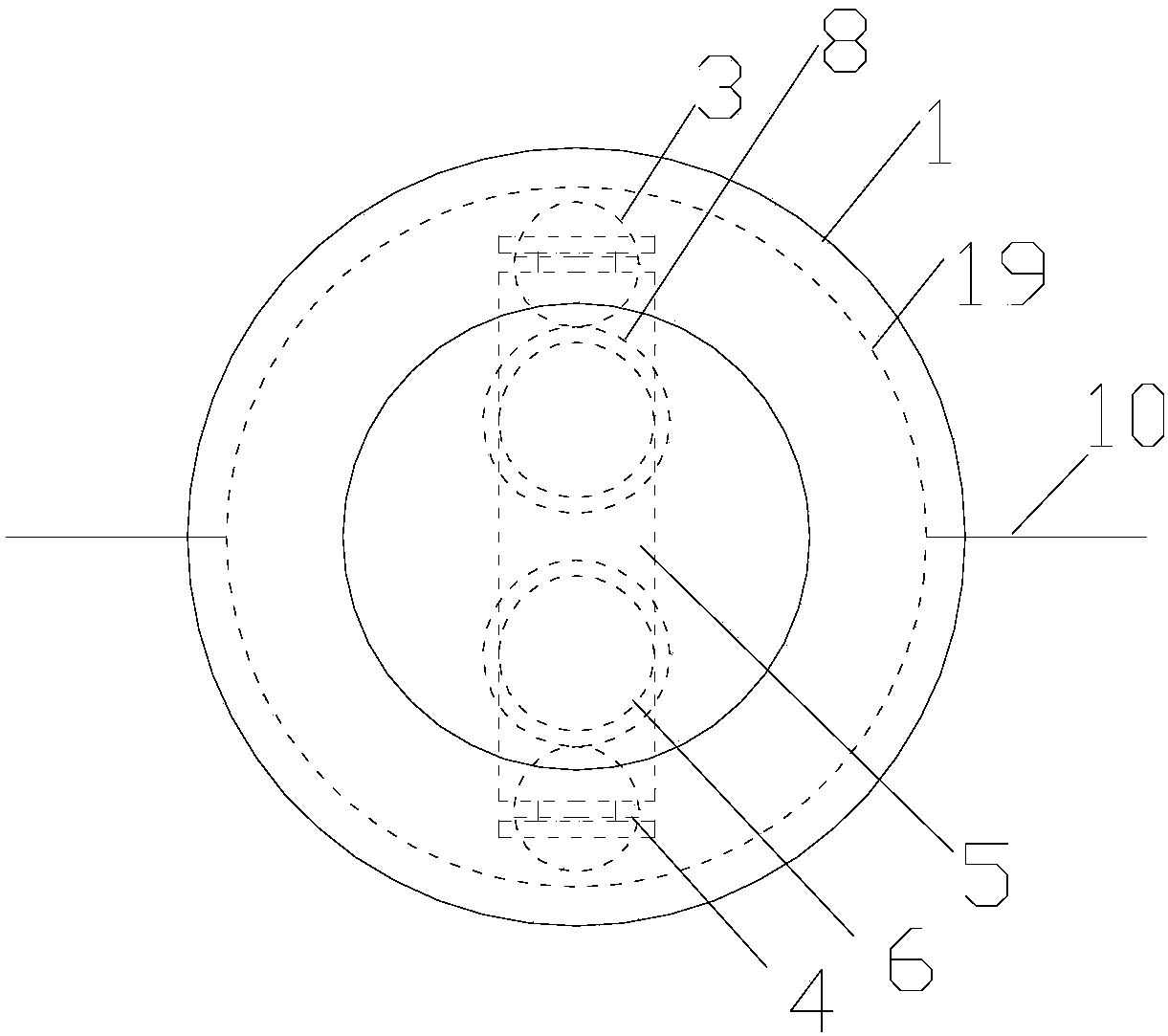

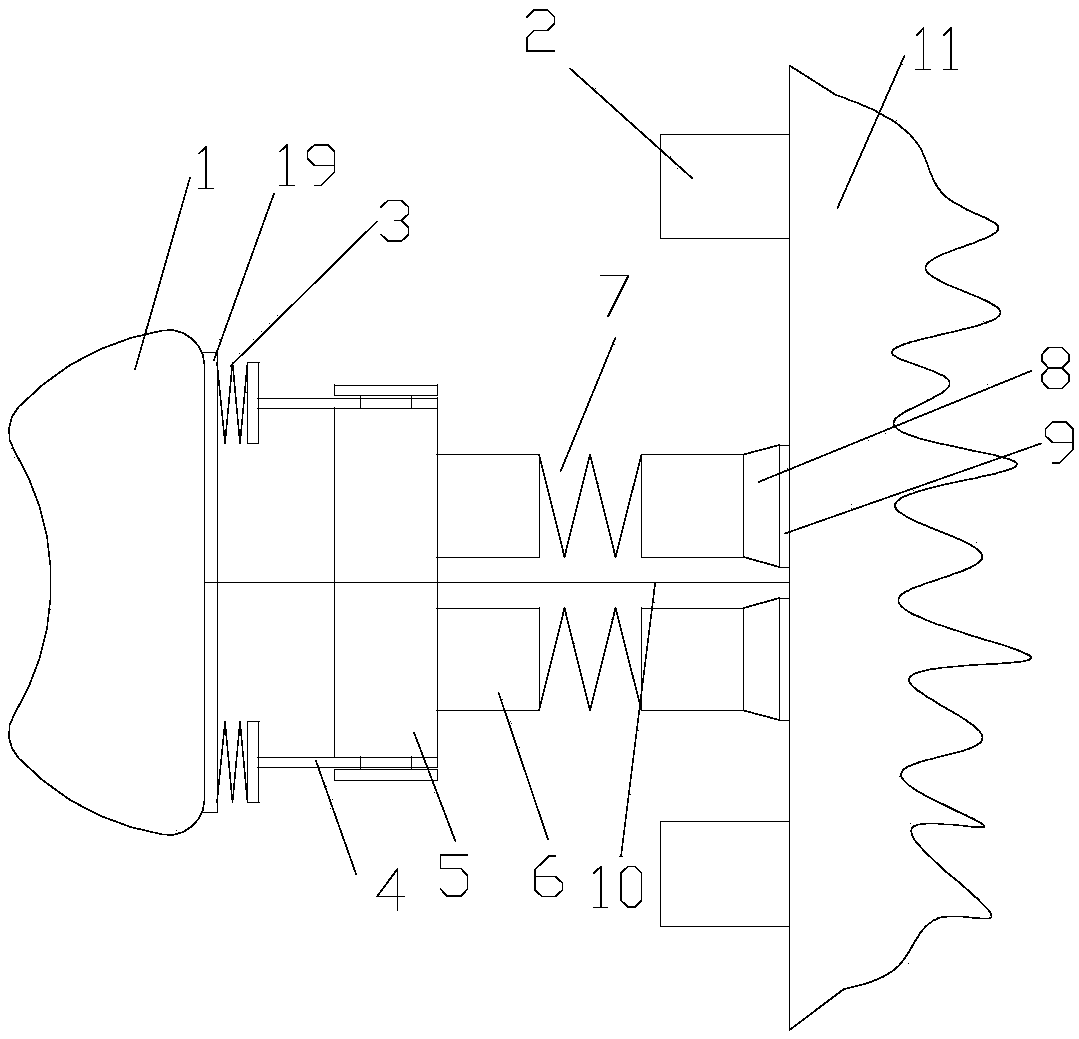

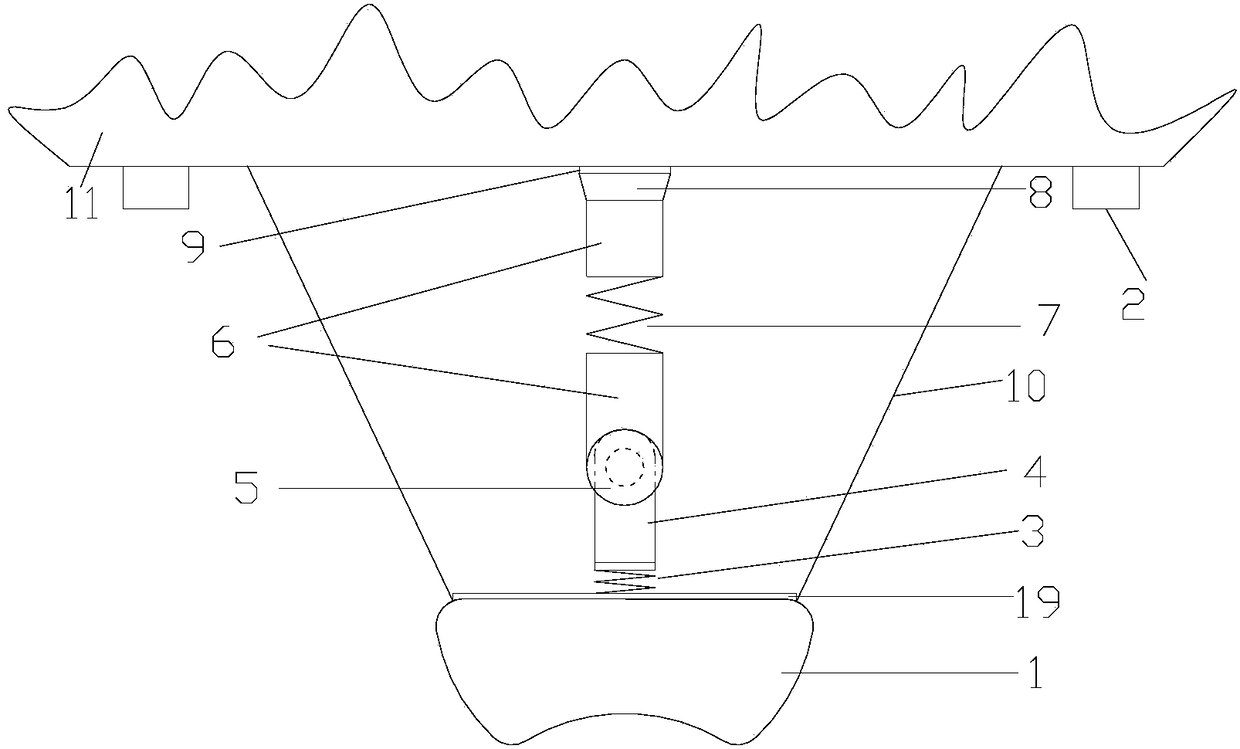

[0026] Such as Figure 1 to Figure 6 As shown, the rotatable multi-layer energy-absorbing wharf fender of the present invention includes a fender body 1, and the fender body 1 is connected to an anti-shock plate 19, and the anti-shock plate 19 is connected to a pair of springs 3, and the springs 3 are respectively It is fixedly connected with the rotating arm 4, and the two rotating arms 4 are installed on the two ends of the pivot 5 respectively. There are two upper connecting columns 6 connected below the pivot 5, and the upper connecting column 6 is connected with the lower connecting column through the rubber spring 7, and the lower connecting column 6 is connected with the lower connecting column through the rubber spring 7. The connecting column is connected to the wharf 11 through the base 8, and a rubber pad 9 is arranged between the base 8 and the wharf 11.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com