Synchronous towing, pushing and tunneling device of underground box culvert or pipeline construction

A technology for pipeline construction and box culverts, applied in pipeline laying and maintenance, tunnels, pipes/pipe joints/pipe fittings, etc. It can solve the problem of increasing the workload and corresponding costs of rectification, the deviation of the machine head from the travel axis, and the pin holes of pipe joints. In order to improve the culvert section increase, the construction excavation length is longer, and the floor space can be saved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings, but the present embodiments are not intended to limit the present invention, and any similar structures and similar changes of the present invention should be included in the protection scope of the present invention.

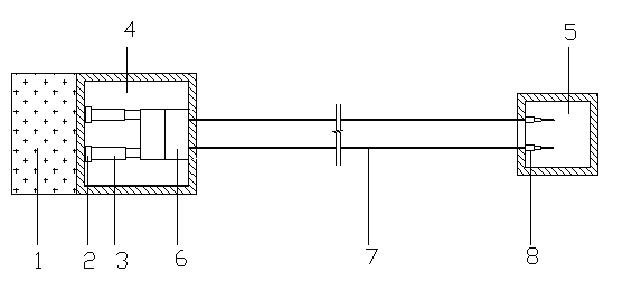

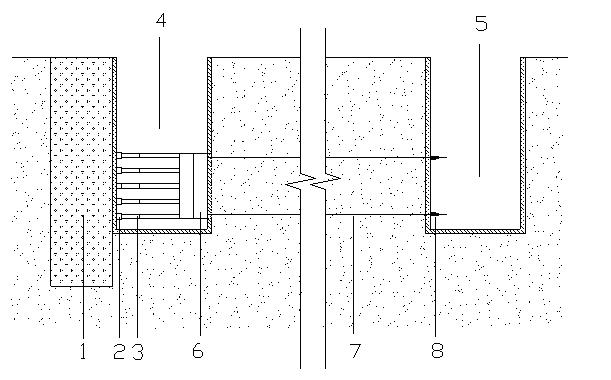

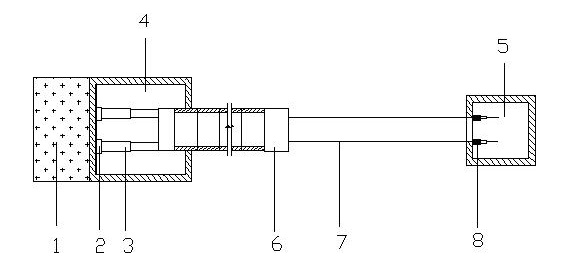

[0022] Such as Figure 1-Figure 4 As shown, the embodiment of the present invention provides a synchronous traction and jacking excavation device for underground buried box culvert or pipeline construction. Two working wells are built at both ends of the design axis of the box culvert or pipeline, which are respectively departure shafts 4 and the receiving shaft 5; it is characterized in that: the device includes a push jack group 3, a tunneling head 6, a pulling jack group 8 and a plurality of stay cables 7;

[0023] The push jack group 3 is installed in the departure shaft 4;

[0024] A cable reaction force wall is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com