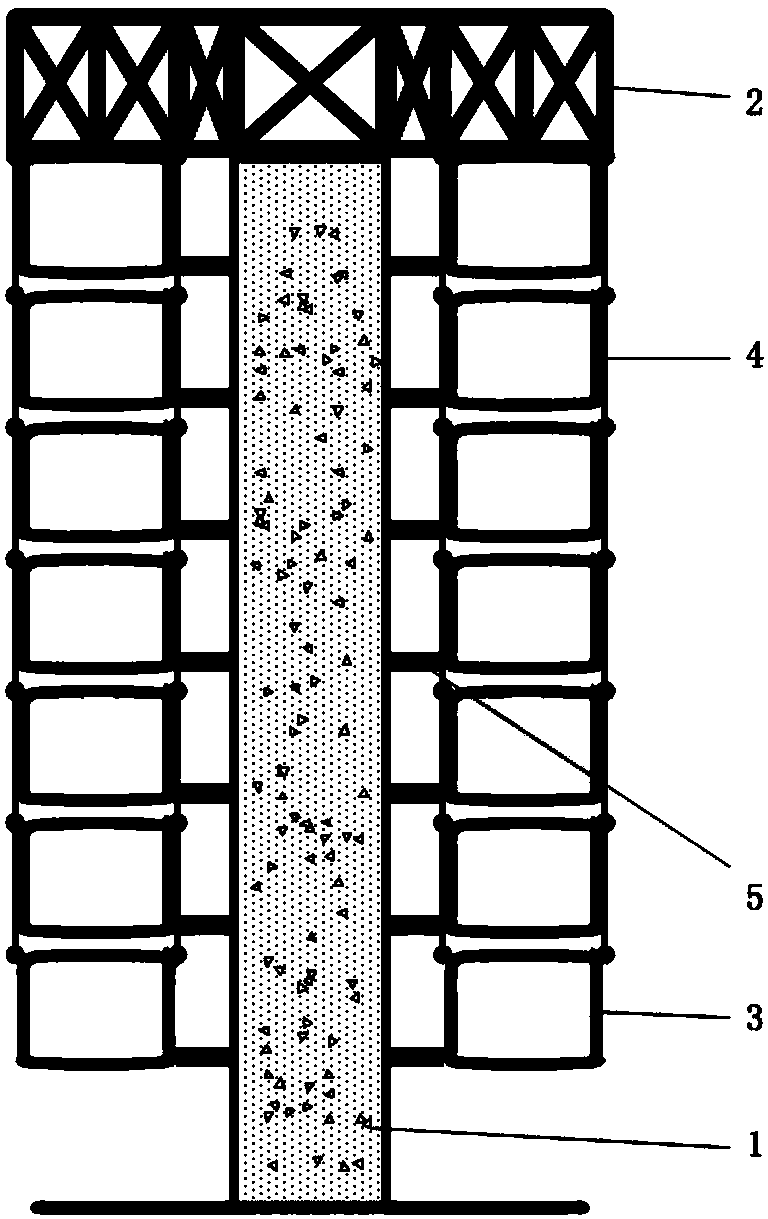

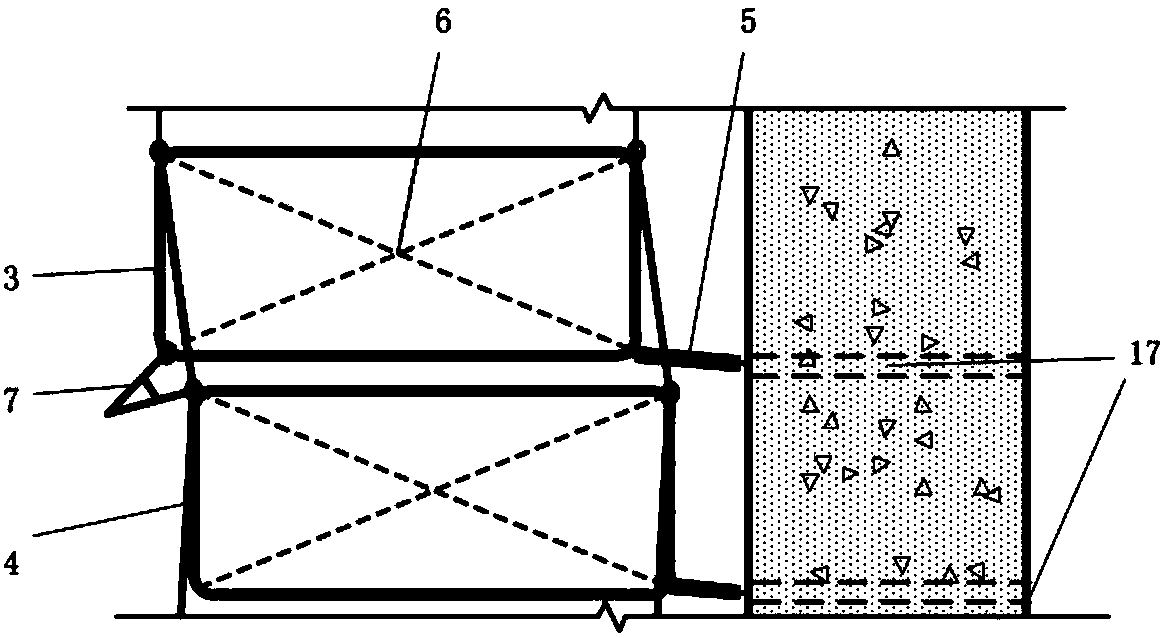

A flexible suspended modular building structure

A technology of building structure and flexible suspension, which is applied in the direction of building components, special structures, building structures, etc. It can solve problems such as increasing the weight of the structure, affecting the use function, and unreasonable structural form, so as to save consumption, avoid collisions, and avoid damage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

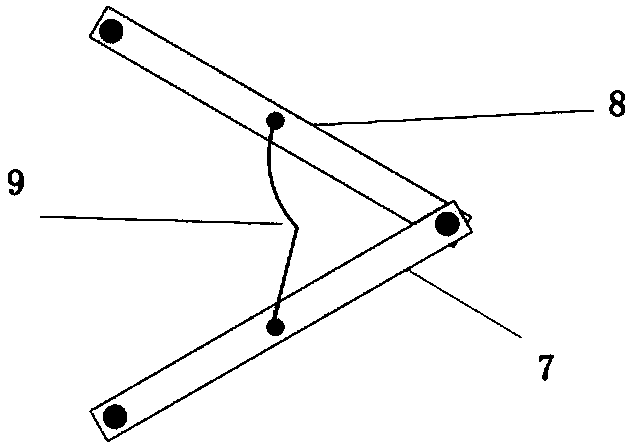

Method used

Image

Examples

Embodiment approach

[0033] To provide exemplary embodiments, three methods of installing suspension section modules are set forth below:

[0034] Method 1, aligning and stacking in place:

[0035] 1. The bottom platform is installed in place. The function of this platform is to bear the temporary vertical load of the modules above it. If the bottom layer of the structure is designed with stackable modules, install the bottom layer modules directly.

[0036] 2. After the modules or platforms on the lower floor are installed, install temporary pads. The function of the pads is to reserve vertical space so that in the final formed system, the modules do not touch vertically; and after the pads are installed and leveled, Hoist the modules on the current floor.

[0037] 3. After the modules of each layer are in place in sequence, install suspension rods and limit buffer devices, install dampers between the core tube structure and modules, and connect other pipelines.

[0038] 4. Remove the temporar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com