Connection joint of concrete filled steel tubular column and beams

A technology for steel pipe concrete columns and connecting nodes, which is applied in the direction of construction and building construction, and can solve problems such as difficult implementation, potential safety hazards, and high welding process requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

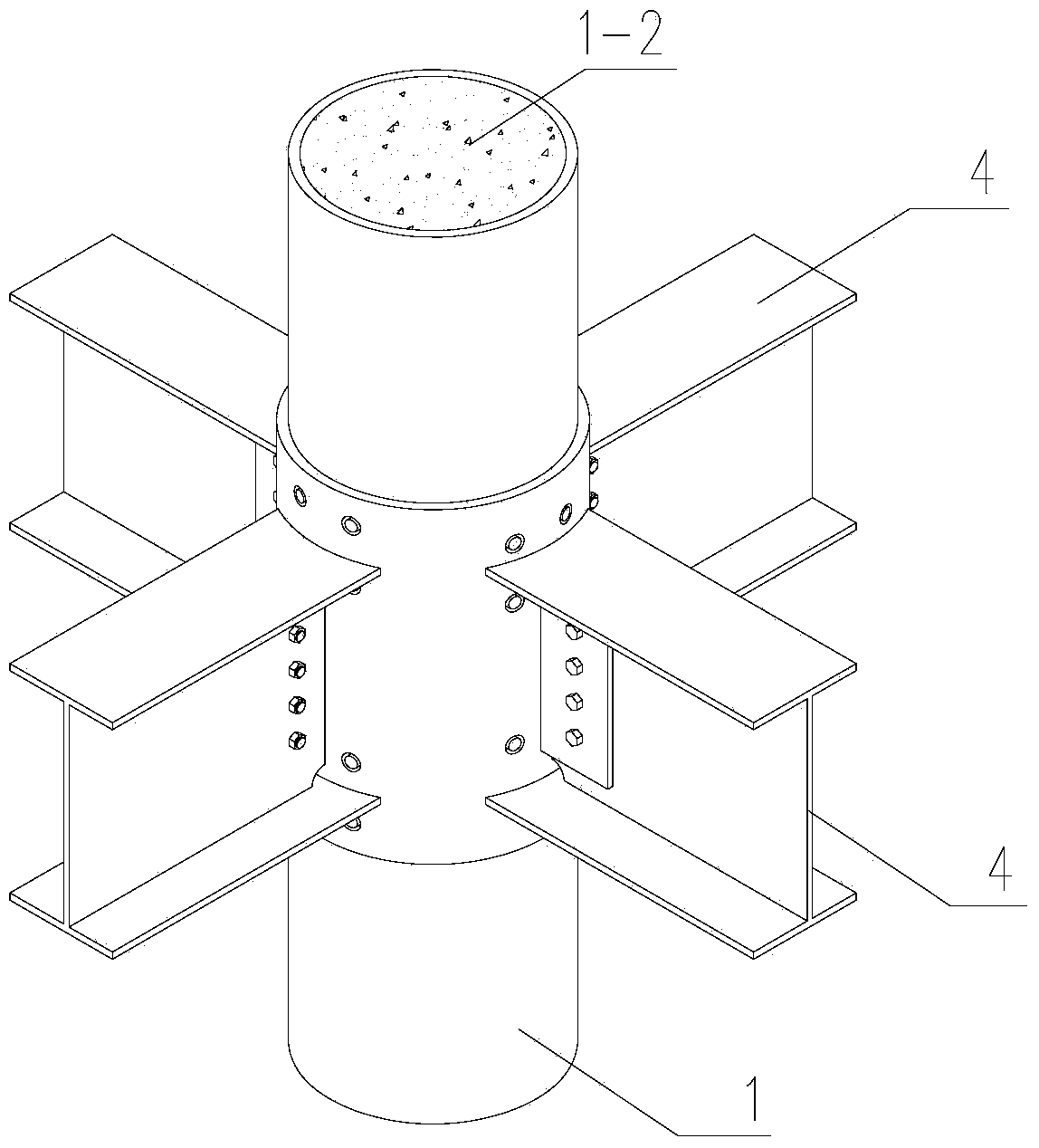

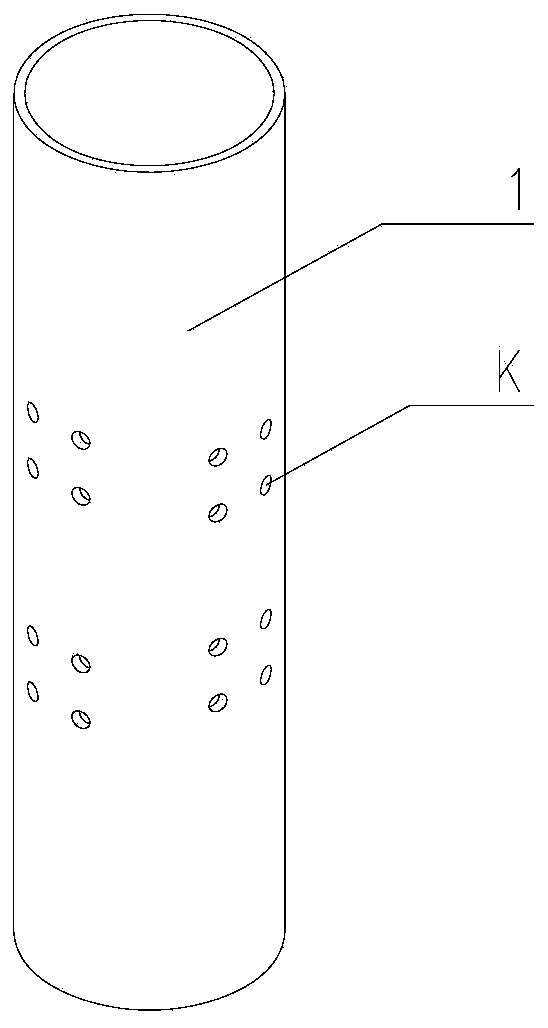

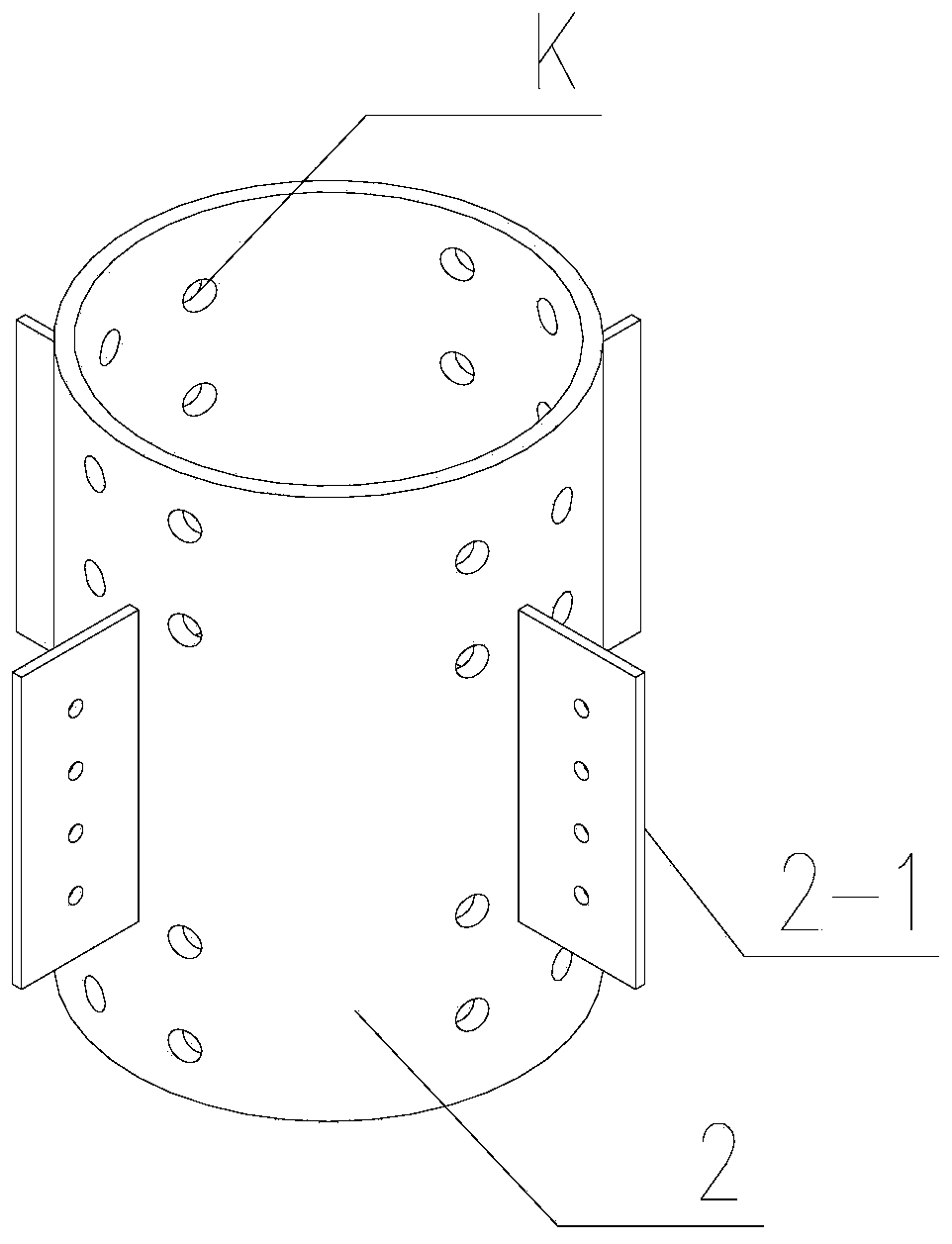

[0033] The present invention is a connection node between a steel pipe concrete column and a beam. When the steel pipe concrete column is a central column, it needs to be connected with four vertical beams. The steel sleeve 2 is a steel pipe conforming to the shape of the steel pipe concrete column, and its surface is radially spaced at 90 degrees. Four steel connecting plates 2-1 are connected; the four steel connecting plates 2-1 are connected with corresponding bolts of the webs of the beam end H-shaped steel joints 4 of the corresponding four beams, and the beam end H-shaped steel joints 4 are connected by corresponding bolts. The ends of the upper and lower flanges are respectively welded to the wall of the steel sleeve 2, and the rest are as described above, such as Figure 1-6 shown.

Embodiment 2

[0035] The present invention is a connection node between a steel pipe concrete column and a beam. When the column is a side column, it is connected with three direction beams at intervals of 90 degrees on one side of the column. The steel sleeve 2 is made of a 1 / 2 circular steel sleeve It is formed by kissing with the corresponding half of the square steel sleeve. Three steel connecting plates 2-1 are vertically connected in the middle of the arc surface steel plate of the steel sleeve 2 and on both sides of the square steel sleeve, and through the The three steel connecting plates 2-1 are connected with corresponding bolts to the webs of the beam-end H-shaped steel connectors 4 of the corresponding three beams, and the upper and lower flange plate ends of the beam-end H-shaped steel connectors 4 are connected to the ends of the steel sleeve 2 respectively. The cylinder wall is correspondingly welded; the rest are as mentioned above, see Figure 7-Figure 9 .

Embodiment 3

[0037] The invention relates to a connection node between a steel pipe concrete column and a beam. When the column is a corner column, the column is connected to two mutually perpendicular beams. The steel sleeve 2 consists of a pair of 1 / 4 arc steel plates and a pair of equal-width angle steel plates. Corresponding to the kissing composition, the two corresponding plates on the radial side of a pair of equal-width angle steel plates are respectively provided with steel connecting plates 2-1, and the two steel connecting plates 2-1 at an angle of 90° are connected to the The webs of the beam-end H-shaped steel connector 4 of the corresponding two beams are connected by corresponding bolts, and the upper and lower flange plate ends of the beam-end H-shaped steel connector 4 are respectively welded to the wall of the steel sleeve 2; the rest are as before described, see Figure 10-Figure 12 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com