Steel column and beam structure with corrugated steel web and special welding device thereof

A corrugated steel web and welding device technology, applied in auxiliary devices, welding equipment, truss structures, etc., can solve the problems of poor anti-overturning performance, easy torsion of I-beam steel beams, low compressive strength, etc., to achieve Strong anti-seismic performance, saving steel and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

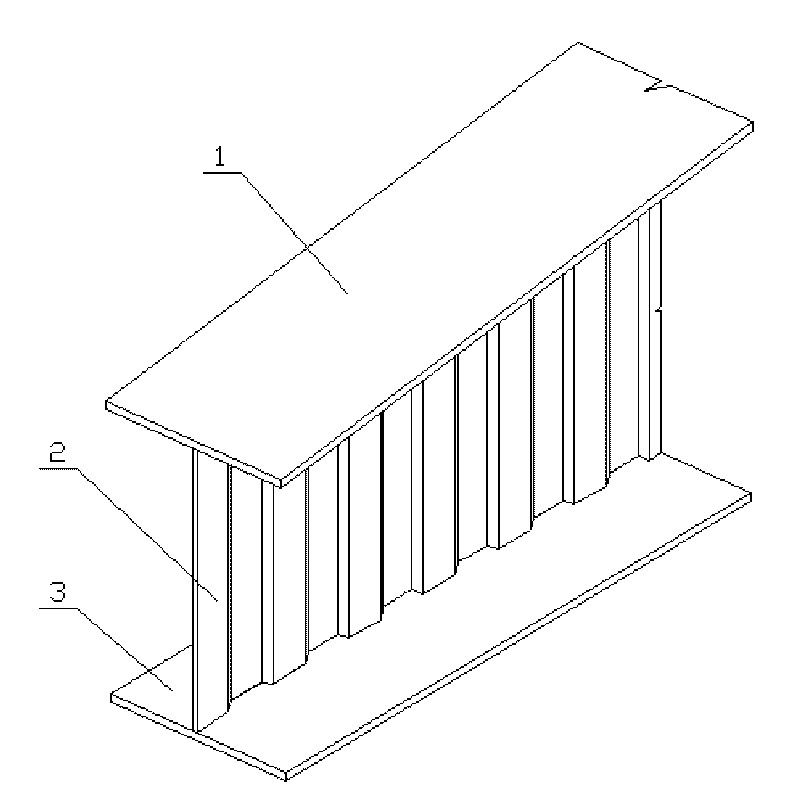

[0028] Corrugated steel web steel column steel beam structure and special welding devices, such as figure 1 , 2 , 7, 8, and 9, including an upper wing 1, a lower wing 3, and a web 2 arranged between the upper wing 1 and the lower wing 3, the upper wing 1 and the lower wing 3 is a plate with a thickness of 5mm, and the web 2 is a corrugated steel web with a thickness of 5mm. 1. The section of the lower wing 3 and the web 2 is "I" shape, the web 2 and the upper wing 1 are connected by welding, and the web 2 and the lower wing 3 are connected by welding. Corrugated steel web The web between the upper flange and the lower flange of the steel column steel beam adopts corrugated steel web, so under the premise of satisfying the same structural strength and mechanical properties, the I-beam with corrugated steel web is also better than the ordinary I-beam The beam saves more steel, and has an anti-twist effect that cannot be compared with ordinary I-shaped beams.

[0029] The uppe...

Embodiment 2

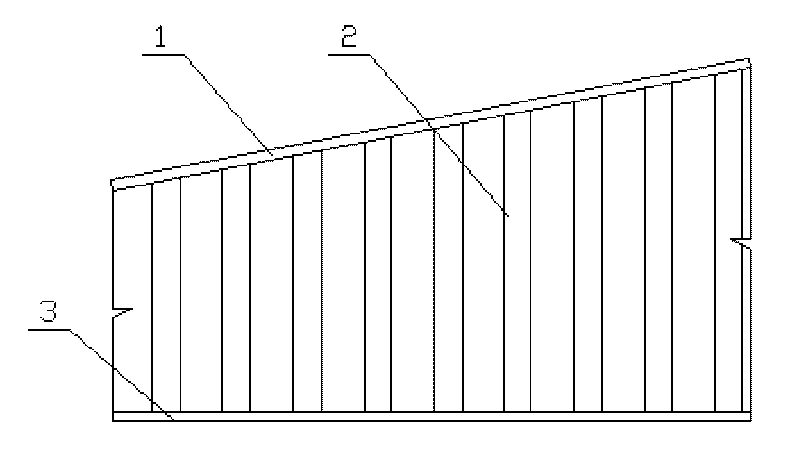

[0036] Corrugated steel web steel column steel beam structure and special welding devices, such as image 3 , 4, 7, 8, and 9, including an upper wing 1, a lower wing 3, and a web 2 arranged between the upper wing 1 and the lower wing 3, the upper wing 1 and the lower wing 3 is a plate with a thickness of 10mm, web 2 is a corrugated steel web with a thickness of 6mm, and the surfaces of upper flange 1, lower flange 3 and web 2 are prepared with a roughness of 120μm; 1. The section of the lower wing 3 and the web 2 is "I" shape, the web 2 and the upper wing 1 are connected by welding, and the web 2 and the lower wing 3 are connected by welding. Corrugated steel web The web between the upper flange and the lower flange of the steel column steel beam adopts corrugated steel web, so under the premise of satisfying the same structural strength and mechanical properties, the I-beam with corrugated steel web is also better than the ordinary I-beam The beam saves more steel, and has ...

Embodiment 3

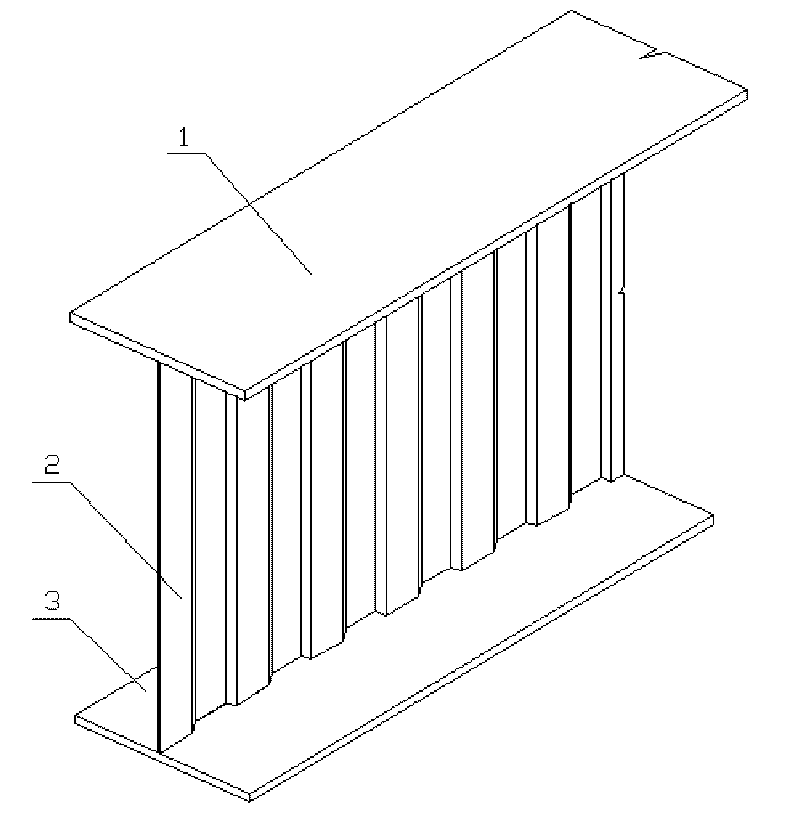

[0044] Corrugated steel web steel column steel beam structure and special welding devices, such as Figure 5 , 6 , 7, 8, and 9, including an upper wing 1, a lower wing 3, and a web 2 arranged between the upper wing 1 and the lower wing 3, the upper wing 1 and the lower wing 3 is a plate with a thickness of 20mm, web 2 is a corrugated steel web with a thickness of 8mm, and the surfaces of upper flange 1, lower flange 3 and web 2 are prepared with a roughness of 200μm; 1. The section of the lower wing 3 and the web 2 is "I" shape, the web 2 and the upper wing 1 are connected by welding, and the web 2 and the lower wing 3 are connected by welding. Corrugated steel web The web between the upper flange and the lower flange of the steel column steel beam adopts corrugated steel web, so under the premise of satisfying the same structural strength and mechanical properties, the I-beam with corrugated steel web is also better than the ordinary I-beam The beam saves more steel, and ha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com