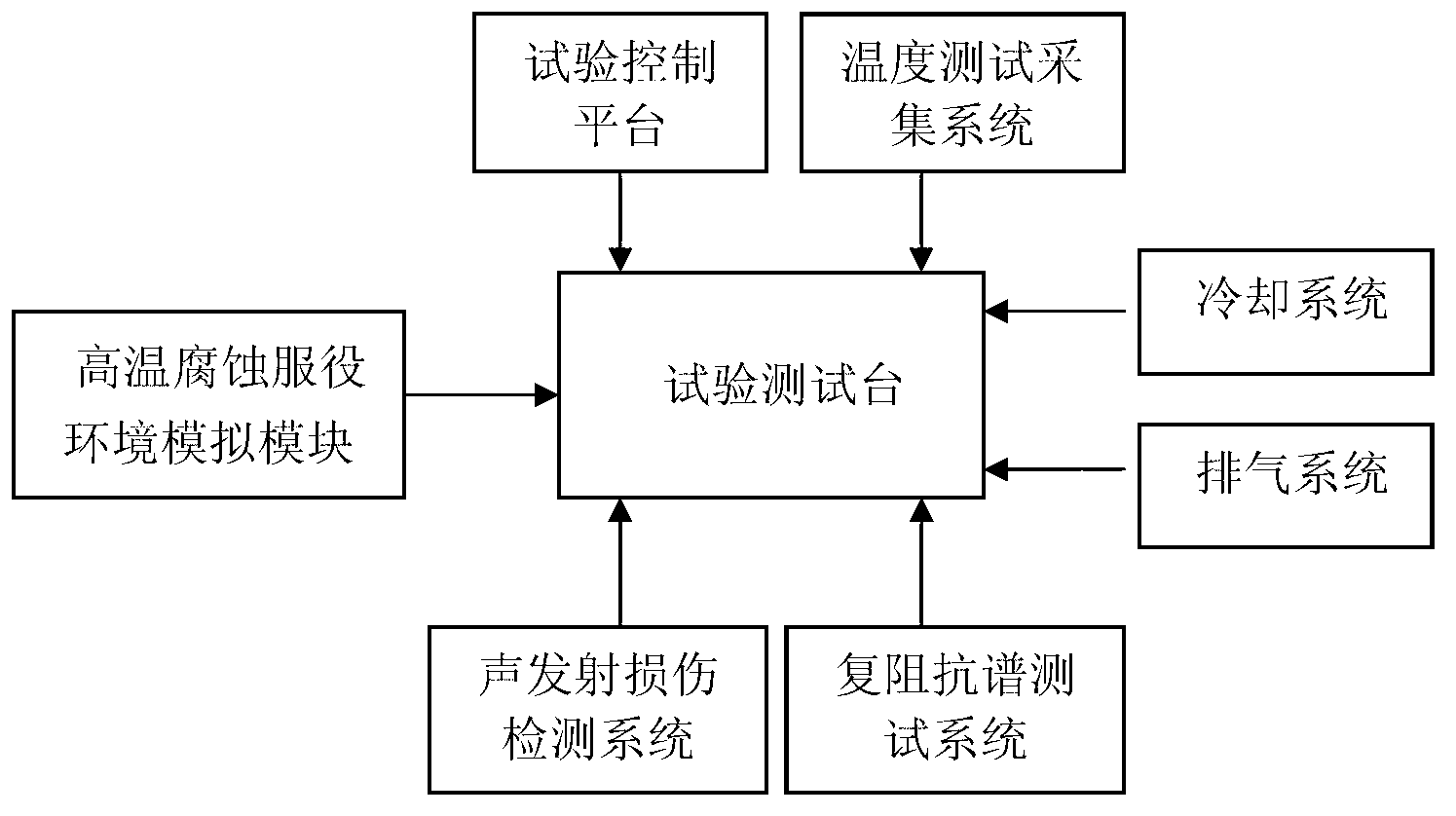

Testing device for simulation and real-time detection of high-temperature deposition corrosion of thermal barrier coatings

A technology of thermal barrier coatings and test devices, applied to measuring devices, weather resistance/light resistance/corrosion resistance, instruments, etc., to achieve the effect of optimized material design, fast heating and cooling rates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

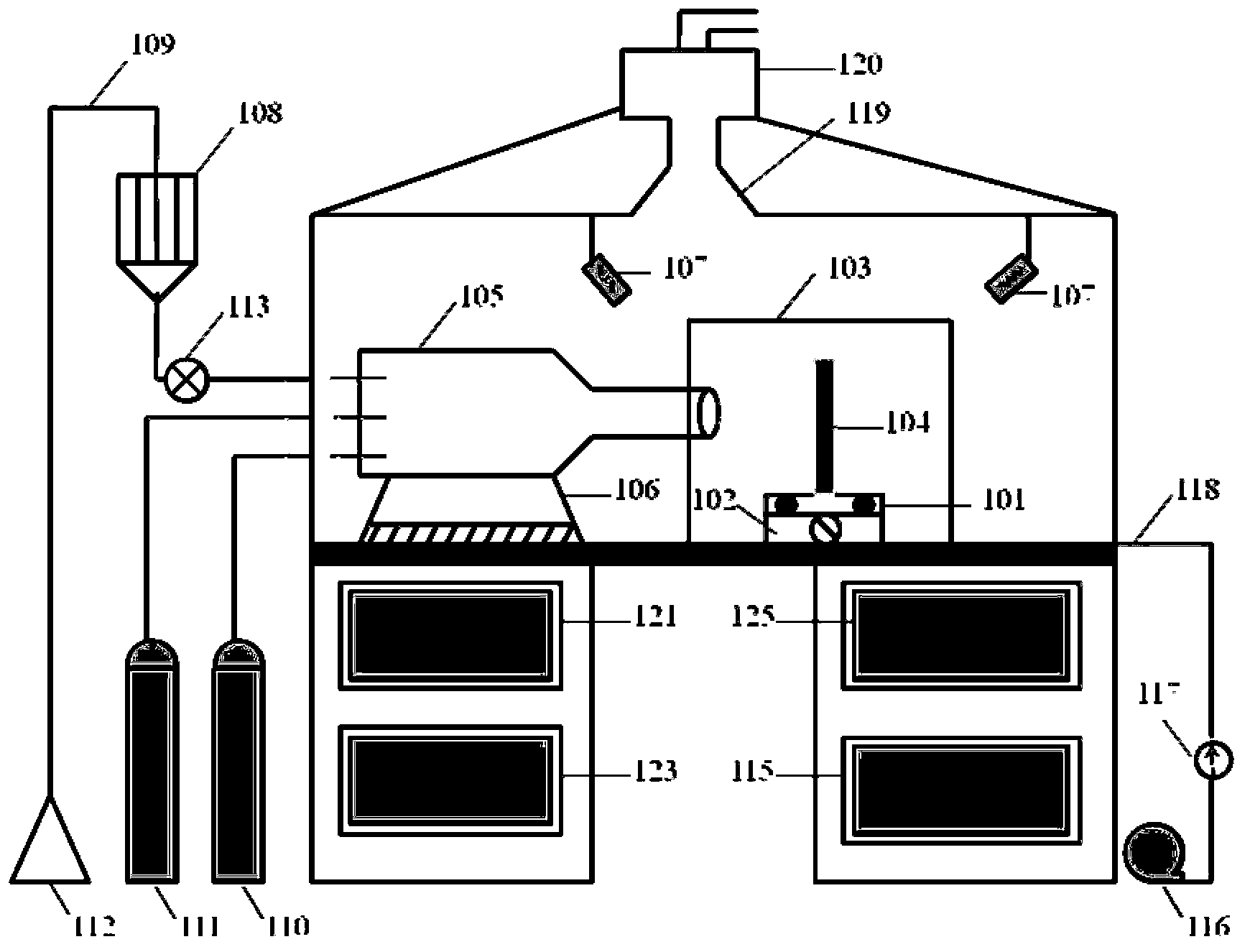

[0023] The present invention provides a test device for simulating and real-time testing the corrosion of high-temperature deposits of thermal barrier coatings. The present invention will be further described below through the description of drawings and specific implementation methods.

[0024] (1) Use this device to perform NaCl, Na 2 o 4 or V 2 o 5 The steps of single corrosive medium simulation test and real-time test are as follows:

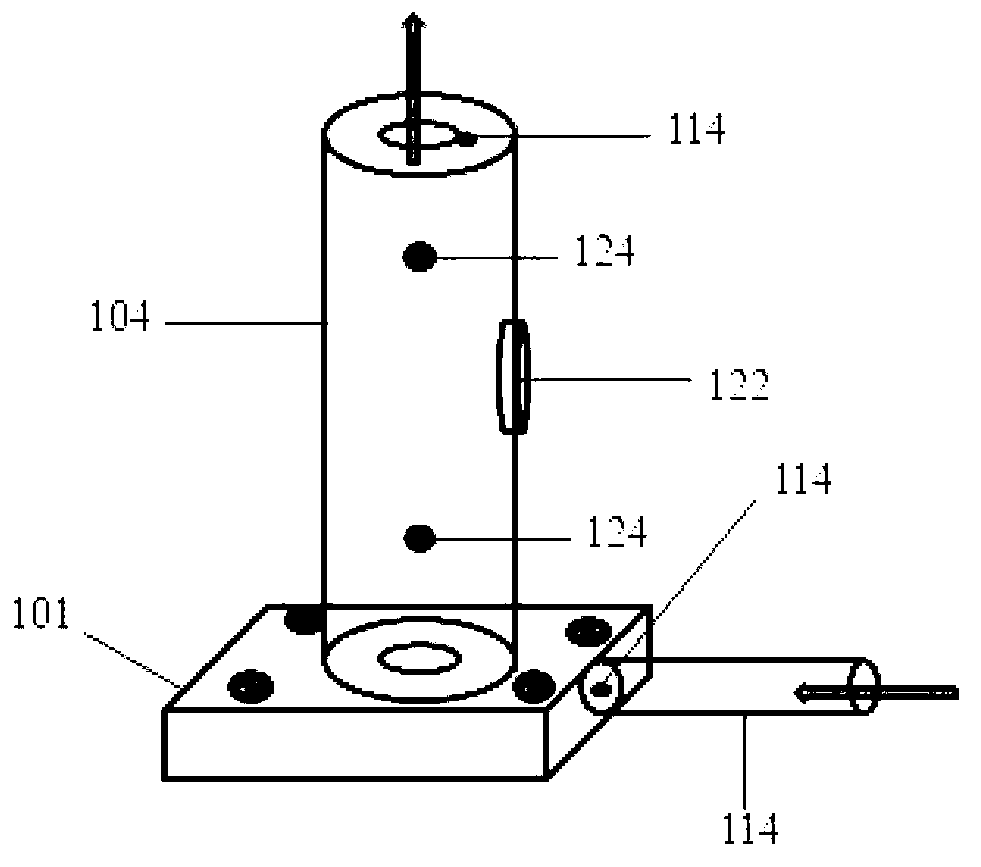

[0025] Step 1: Weld two impedance test electrodes (122) on the free surface of the sample substrate and the surface of the ceramic layer plated with platinum or gold electrodes by spot welding, and connect the other end to the complex impedance spectrum measurement system (121); Two acoustic emission waveguide rods (124) are respectively spot-welded to the two ends of the substrate, and the other end is connected to the sensor of the acoustic emission detection system (123); the infrared thermometer (107) and one thermocouple (114) are fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com