Soft magnetic film inductor and magnetic multi-component alloy thin film

A soft magnetic thin film, multi-component alloy technology, applied in the direction of inductors, inductors/transformers/magnets, fixed inductors, etc., can solve the problem of low resistance value, achieve the effect of low coercive field, save time, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

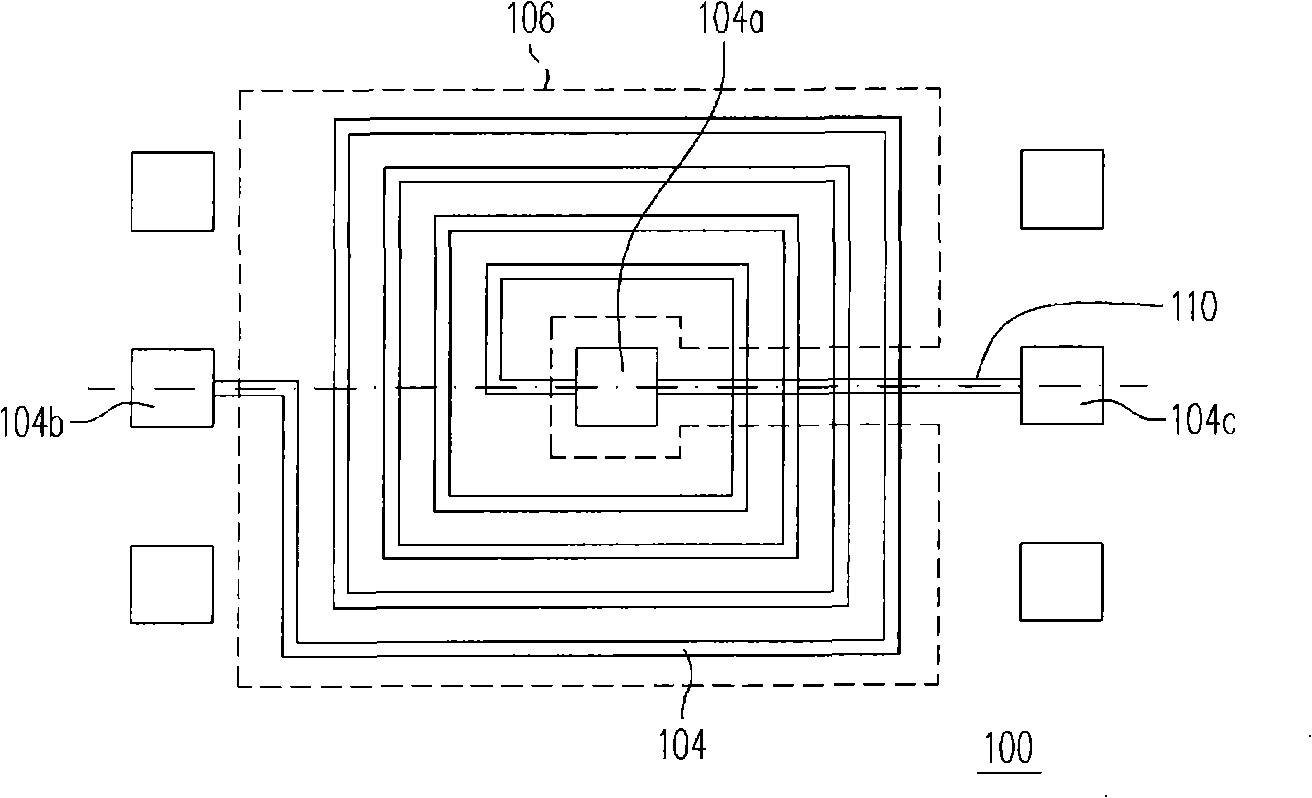

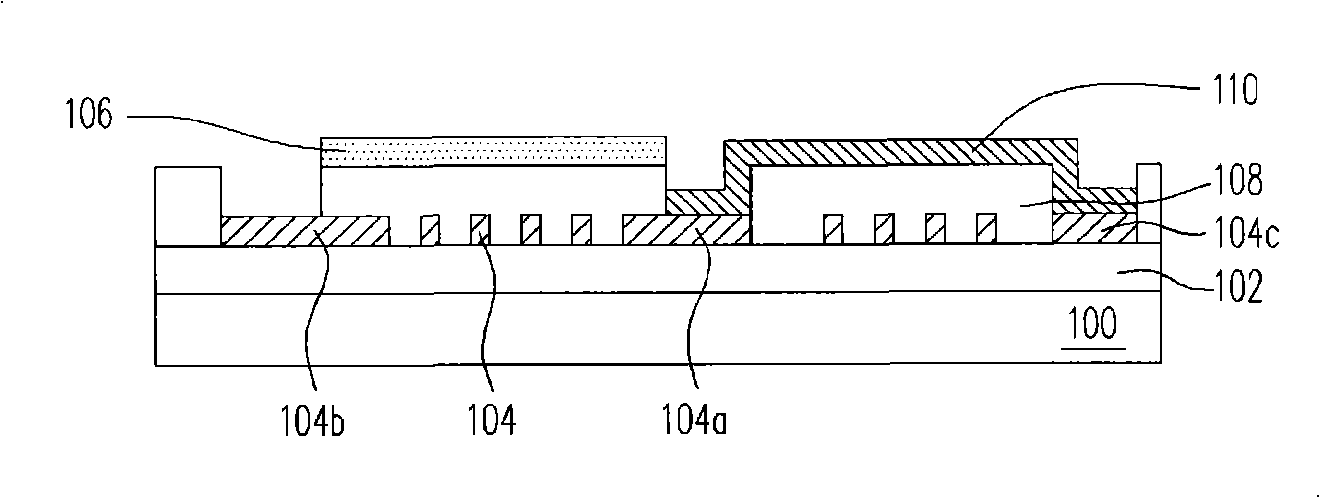

[0075] Experimental Example 1 (Soft Magnetic Thin Film Inductor with FeCoNiAlB Magnetic Film)

[0076] Five alloying elements Fe, Co, Ni, Al, B are selected and smelted into alloy targets. The composition ratio of the alloy target is Fe 42 co 37 Ni 10 al 5 B 6 , the saturation magnetic flux density of the alloy target is 1.66T, and the coercive field is 18Oe.

[0077] Using the manufacturing method of the soft magnetic thin film inductor mentioned above, the FeCoNiAlB thin film is used to manufacture the ferromagnetic thin film inductor. The process conditions of FeCoNiAlB film are: working pressure is 5mtorr, gas flow rate is 18sccm, background pressure is less than 9*10 -6 torr, the working distance is fixed at 5cm, the substrate is silicon oxide (200nm) / n-type Si(100), the coating time is 30min, and the coating power is 53W, and radio frequency magnetron sputtering coating is performed. Then, in order to induce the magnetic anisotropy of the magnetic film, field an...

experiment example 2

[0080] Select six alloying elements Fe, Co, Ni, Al, Cr, Si, and melt them into alloy targets. The composition ratio of alloy targets is Fe 40 co 35 Ni 5 al 5 Cr 5 Si 10 , the saturation magnetic flux density of the alloy target is 1.18T, and the coercive field is 8Oe.

[0081] Then, the FeCoNiAlCrSi ferromagnetic thin film inductor was fabricated, except that the FeCoNiAlCrSi thin film was used as the magnetic multi-element alloy thin film, and the annealing temperature was 200° C., the manufacturing process was the same as that of Experimental Example 1. At this time, the saturation magnetization of the FeCoNiAlCrSi film is 900emu / cm 3 , the coercive field of the hard axis is 2Oe, the anisotropic field strength is about 20Oe, and the film resistivity is 350μΩ-cm. Figure 6 and Figure 7 It is the inductance value and Q value measured by the network analyzer. Such as Figure 6 and Figure 7 As shown, at 800MHz, the FeCoNiAlCrSi ferromagnetic film inductor has a 14% i...

experiment example 3

[0083] Select three alloying elements Fe, Co, B, and smelt them into an alloy target. The composition ratio of the alloy target is (Fe 0.55 co 0.45 ) 90 B 10 .

[0084] Then, using the same production process as in Experimental Example 1, (Fe 0.55 co 0.45 ) 90 B 10 thin films, and tested for various magnetic values. The data of each magnetic value are listed in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com