Polycell collaborative coupling acoustic meta-material design method

An acoustic metamaterial and structural design technology, applied in the field of acoustic metamaterials, can solve the problems of difficult quantitative control of tension, low stiffness of elastic film, and shortened material life, etc., to achieve improved sound insulation performance, excellent sound insulation performance, and improved sound insulation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be described in further detail below in conjunction with the accompanying drawings.

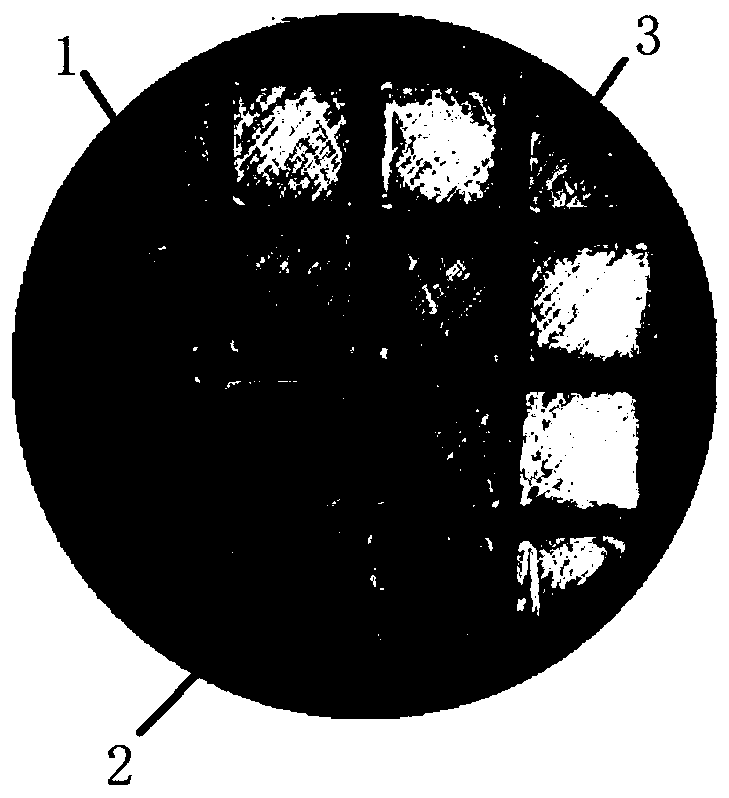

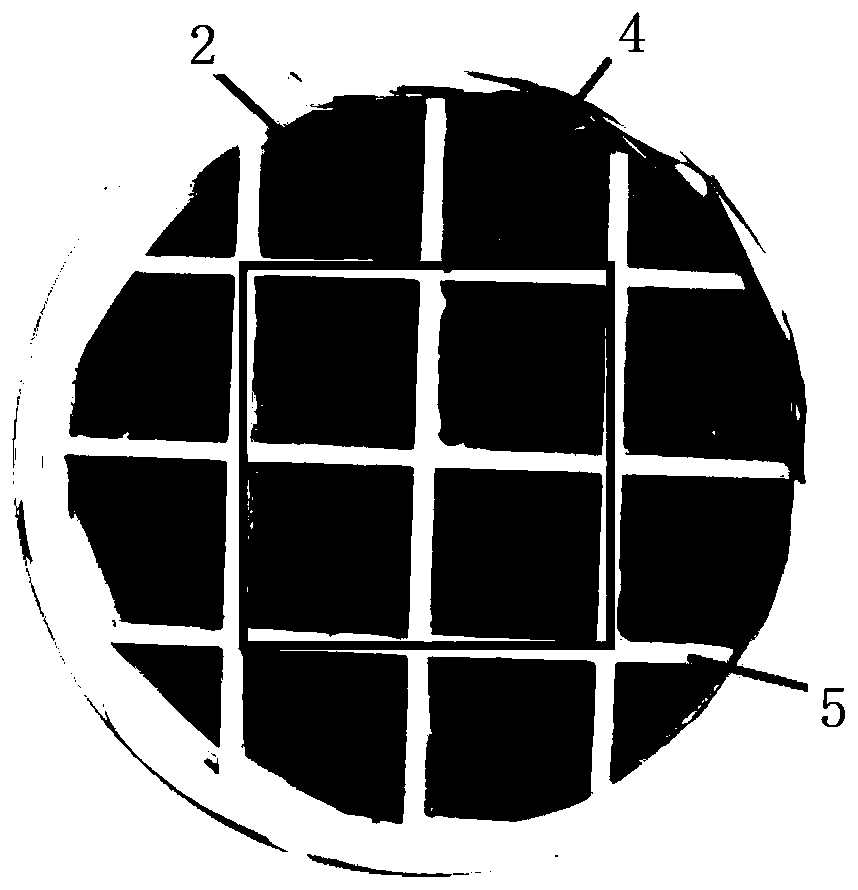

[0043] (1) Design scheme of flexible frame multi-cell cooperative coupling structure

[0044] Looking at all local resonance structures, the overall effect caused by the insufficient localized stiffness of the partition units will attenuate or even completely eliminate the structure's ability to regulate mechanical waves. Therefore, the overall effect has become a major negative factor in the design of local resonance structures. factor. By adopting the flexible frame multi-cell cooperative coupling acoustic metamaterial structure design method provided by the present invention, a class of ultra-light and ultra-thin rigid sheet-type acoustic metamaterial structure with lumped coupling resonance effect is designed. These structures consist of two flexible lightweight polyester (or plastic) frames clamping a thin sheet of rigid nylon 0.2mm thick. Compared wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com