Sound insulation structure with air interlayer and ventilation while sound insulation

一种空气夹层、隔声的技术,应用在隔音、隔绝层、建筑构件等方向,能够解决整体结构复杂、有能耗等问题,达到提高隔声性能、增加散射、隔声性能提高的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

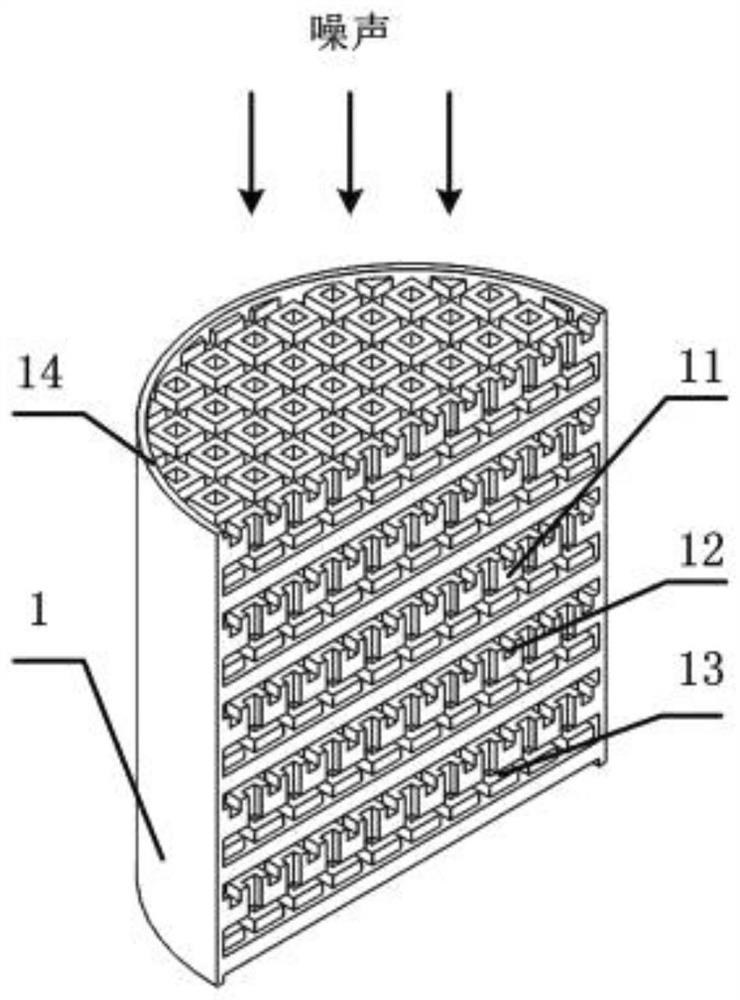

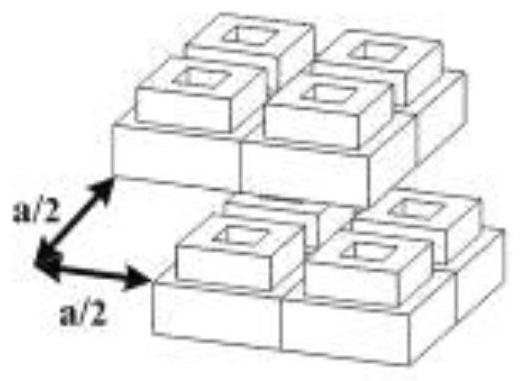

[0023] As shown in Figure 1(a), in this embodiment, the overall shape of the sound insulation structure of the staggered arrangement of grooved perforated plates, that is, the shell 1 is cylindrical, the diameter of the shell 1 is 29.8mm, and the thickness is 30mm. Its overall shape and thickness can be made according to actual engineering needs. This embodiment includes a casing 1 and several layers of perforated plates 11 arranged in the casing 1 , and two adjacent perforated plates 11 are arranged in a staggered manner and are provided with air interlayers 13 . A plurality of grooves 12 are arranged on one side of the perforated plate in two mutually perpendicular perforation directions. Among them, the thickness of the perforated plate is 2mm; the perforated section is square, and the side length of the square is 1mm; the perforation spacing of the perforated plate is 3mm; the width of the groove is 0.8mm, the depth is 0.8mm; the thickness of the air interlayer is 1mm. Th...

Embodiment 2

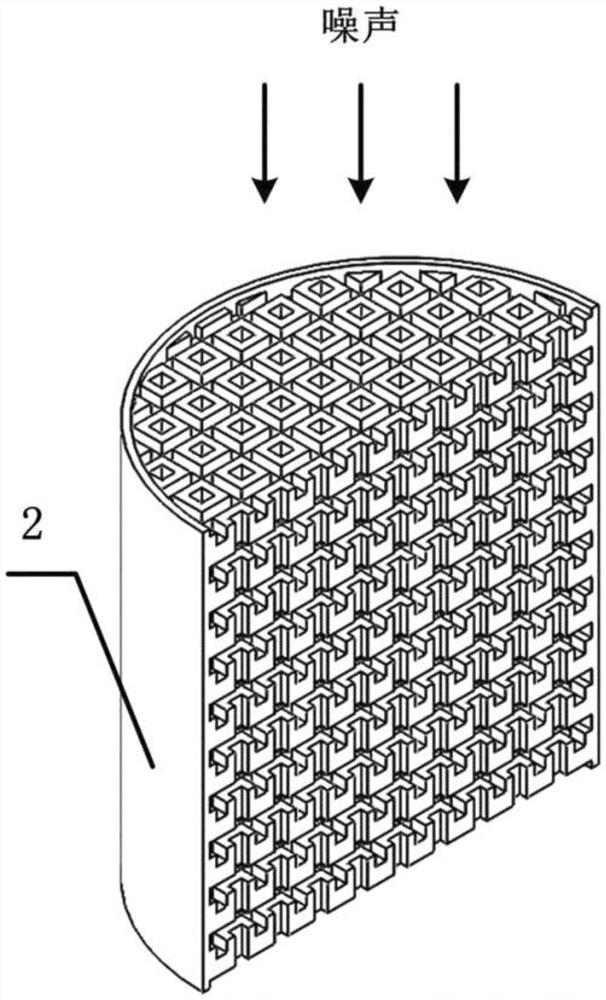

[0028] In this embodiment, the overall shape of the sound insulation structure of the staggered arrangement of the grooved perforated plates is cylindrical, the diameter of the sample is 29.8 mm, and the thickness is 60 mm. In this embodiment, the sound insulation structure of slot-type perforated plates arranged in a row is selected as a comparison, and the overall shape is cylindrical and the thickness is 60mm.

[0029] The SW477 impedance tube manufactured by Beijing Shengwang Shengdian Technology Co., Ltd. was used to test the transmission loss of the staggered sound insulation structure of the grooved perforated plates involved in Example 2 and the sound insulation knots arranged in a row. The test frequency range is 1000Hz-6300Hz. During the test, the side of the sample with the grooves faces the noise source.

[0030] Figure 5 For the same shape (the sample diameter is 29.8mm and the thickness is 60mm), the change of the transmission loss of the staggered sound insul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com