Method for determining ply angle direction and thickness of laminated board composite material

A technology of composite materials and laminates, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as difficulty in finding optimal design solutions for laminate composite materials, waste of materials, poor design solutions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

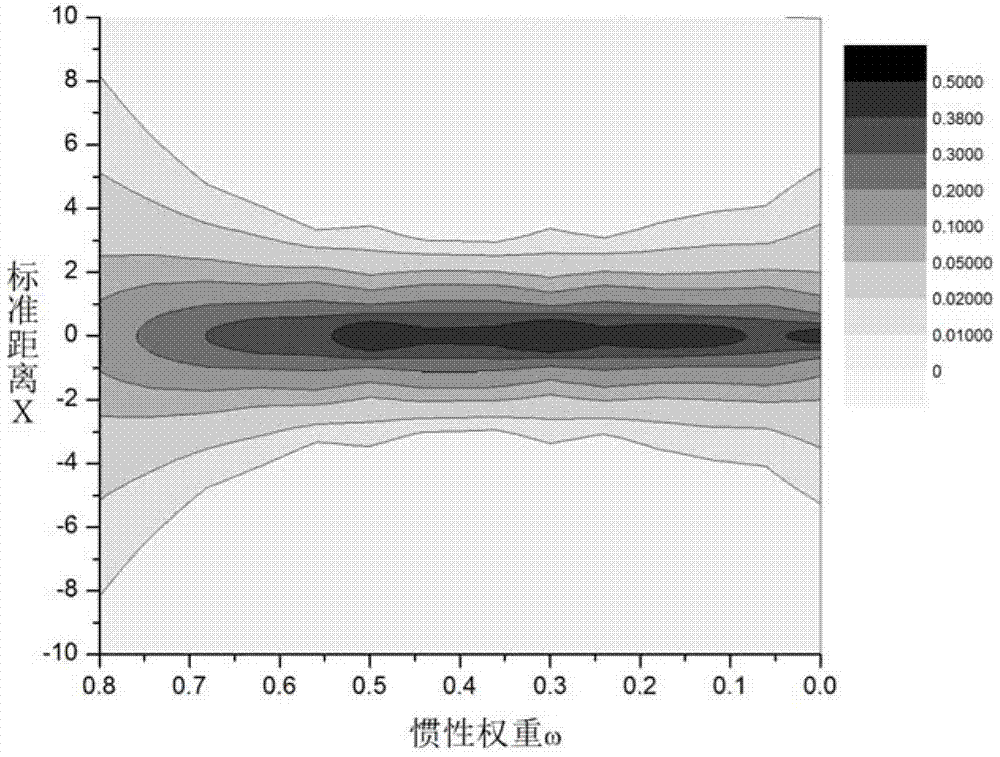

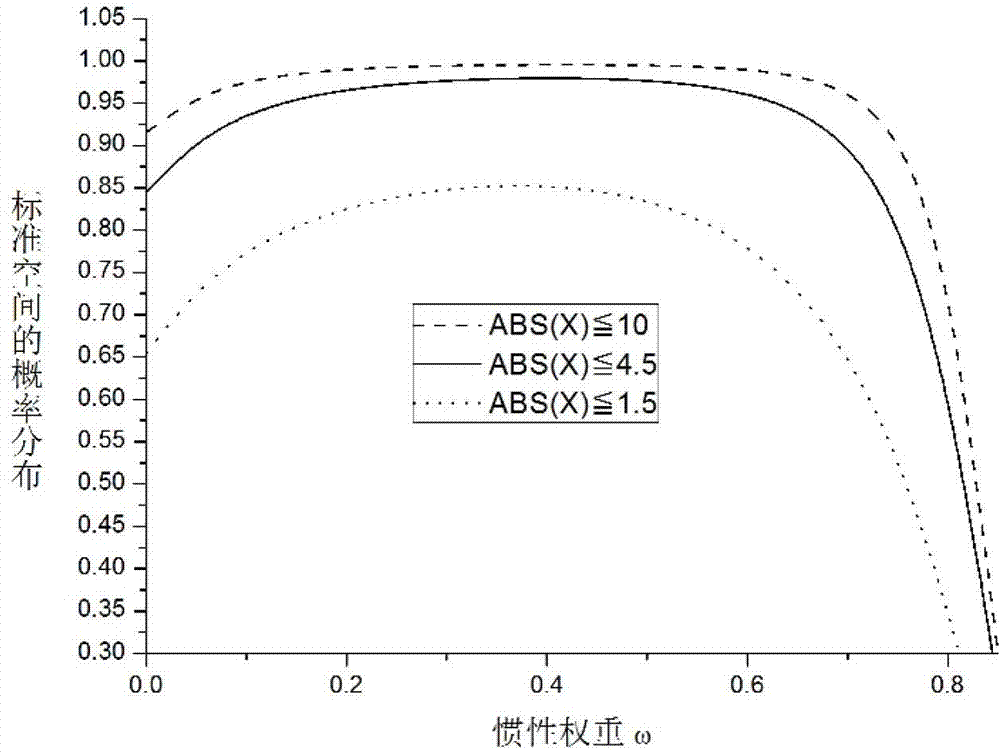

[0036] Such as Figure 5 As shown, the present invention proposes a method for determining laminate composite material design by mixing particle swarm optimization method and mathematical programming, comprising the following steps:

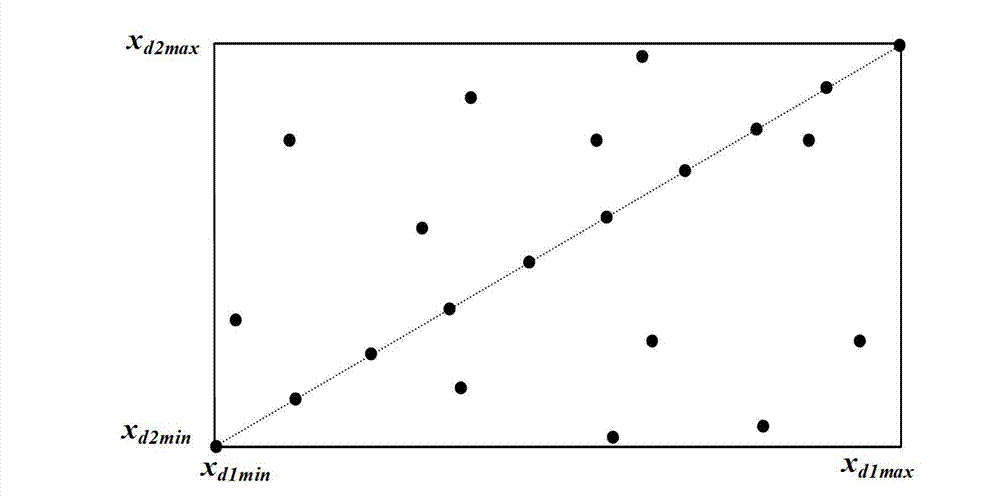

[0037] (1) The ply angle direction and thickness of the laminate composite are the design variables, and the minimum mass or maximum buckling critical load of the laminate composite is the design target f(x C1 ,x C2 ..., x Cd ,x D1 ,x D2 ..., x Ds ), taking the allowable stress of the laminate composite material and the displacement at the specified position as constraints g j (x C1 ,x C2 ...,x Cd ,x D1 ,x D2 ..., x Ds ), j is the constraint number, p is the number of constraints, the constraint number, p is the number of constraints, and the optimization column for laminate composite design is established:

[0038] min f ( ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com