Wide-temperature high-permeability Mn-Zn soft magnetic ferrite material and magnetic core prepared therefrom as well as preparation method thereof

A technology of magnetic permeability of manganese zinc and soft ferrite, applied in the direction of inorganic material magnetism, magnetic core/yoke, electrical components, etc., can solve problems such as dependence on imports

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

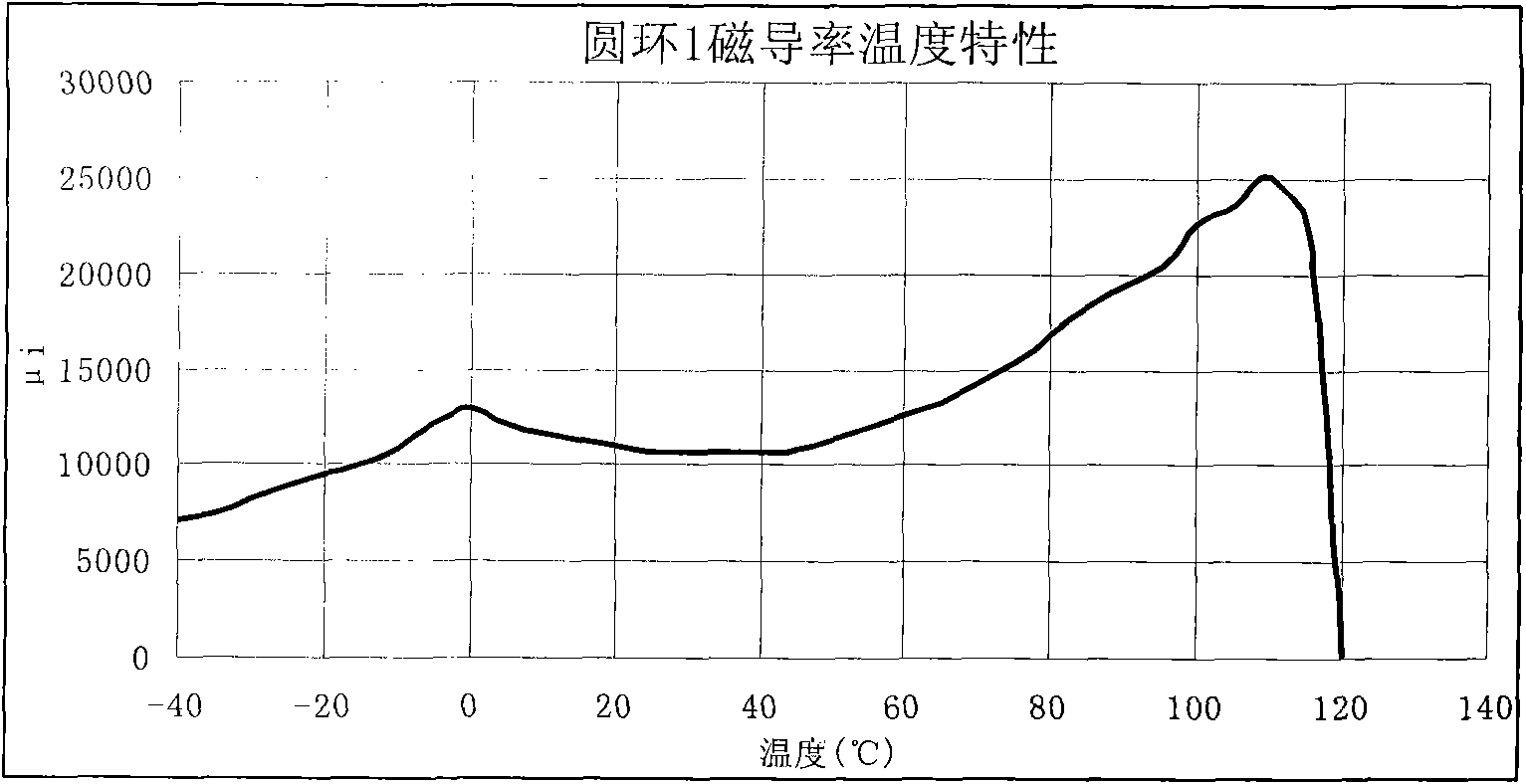

Embodiment 1

[0023] Press Fe 2 o 3 : MnO: ZnO = 50.5: 26.5: 23.0mol% of the formula for a batching, wherein Fe 2 o 3 Adopt Japanese Kawasaki iron red, purity ≥ 99.5wt%, MnO converted to Mn 3 o 4 , using high-purity Mn from Hunan Jinrui 3 o 4 , Mn purity ≥ 70.8wt%, ZnO adopts ZnO from Haimen, Zhejiang, with purity ≥ 99.7wt%. Pour the three raw materials into a mixing tank, add a dispersant and deionized water, fully stir and mix, and perform a ball mill for 4 to 6 hours. Spray drying and pre-calcination are carried out. The pre-calcination temperature is 860-960° C. and the pre-calcination time is 60-90 minutes to obtain a calcined material.

[0024] The calcined material is used for secondary batching, put into a ball mill for secondary ball milling, and three groups of auxiliary materials A, B and C are added, and the auxiliary material of group A is CaCO 3 , CuO, Nb 2 o 5 The mixture, its total content is 500ppm. The composition of the B group auxiliary material is MoO 3 、BiO...

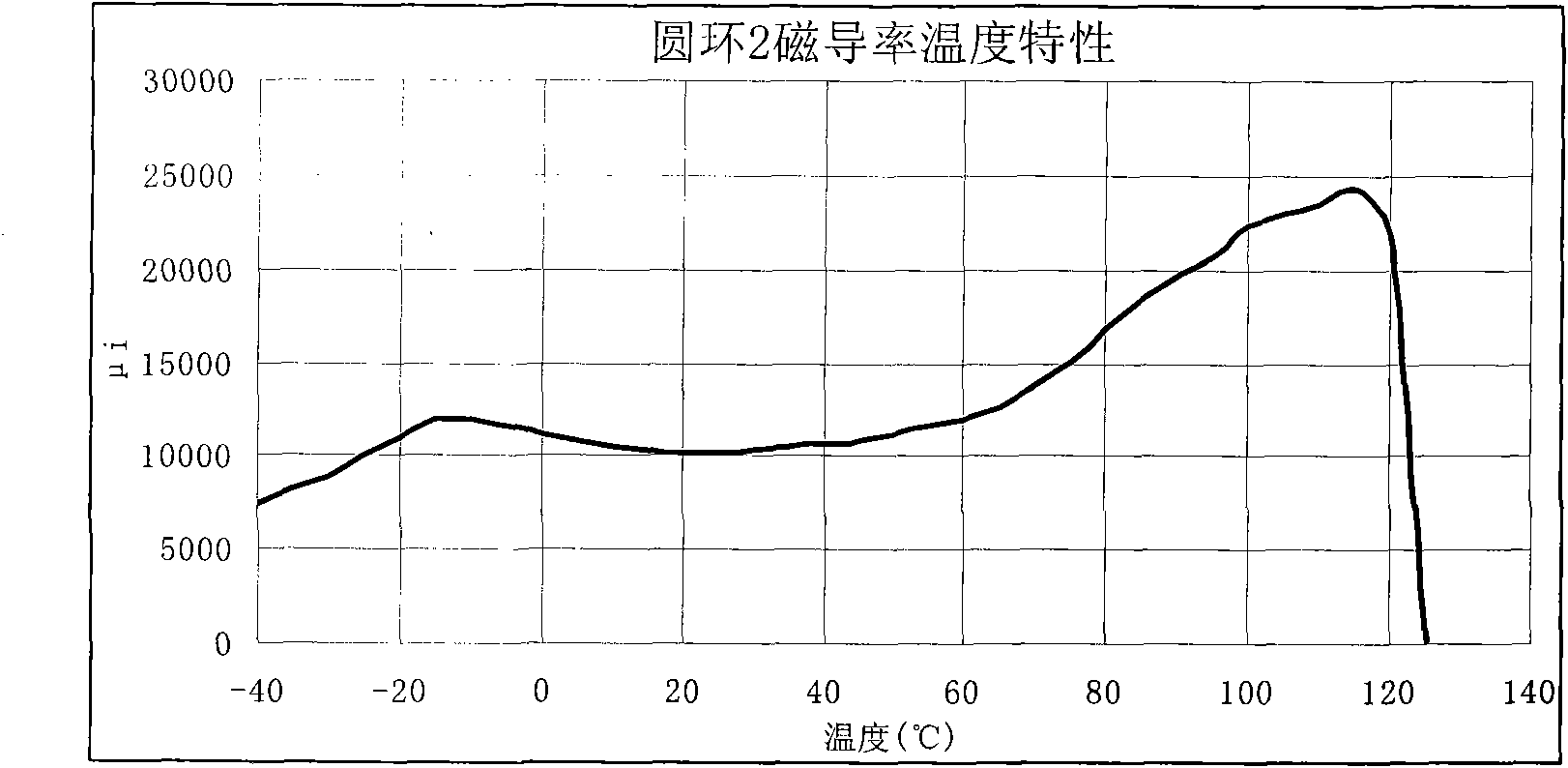

Embodiment 2

[0030] Press Fe 2 o 3 : MnO: ZnO = 51.5: 25.5: 23.0mol% of the formula for a batching, where Fe 2 o 3 Adopt Japanese Kawasaki iron red, purity ≥ 99.5wt%, MnO converted to Mn 3 o 4 , using high-purity Mn from Hunan Jinrui 3 o 4 , Mn purity ≥ 70.8wt%, ZnO adopts ZnO from Haimen, Zhejiang, with purity ≥ 99.7wt%. Pour the three raw materials into a mixing tank, add a dispersant and deionized water, fully stir and mix, and perform a ball mill for 4 to 6 hours. Spray drying and pre-calcination are carried out. The pre-calcination temperature is 860-960° C. and the pre-calcination time is 60-90 minutes to obtain a calcined material.

[0031] The calcined material is used for secondary batching, put into a ball mill for secondary ball milling, and three groups of auxiliary materials A, B, and C are added. The auxiliary material of group A is CaCO with a weight percentage of 300ppm 3 and CuO, the composition of the B group auxiliary material is MoO with a weight percentage of 7...

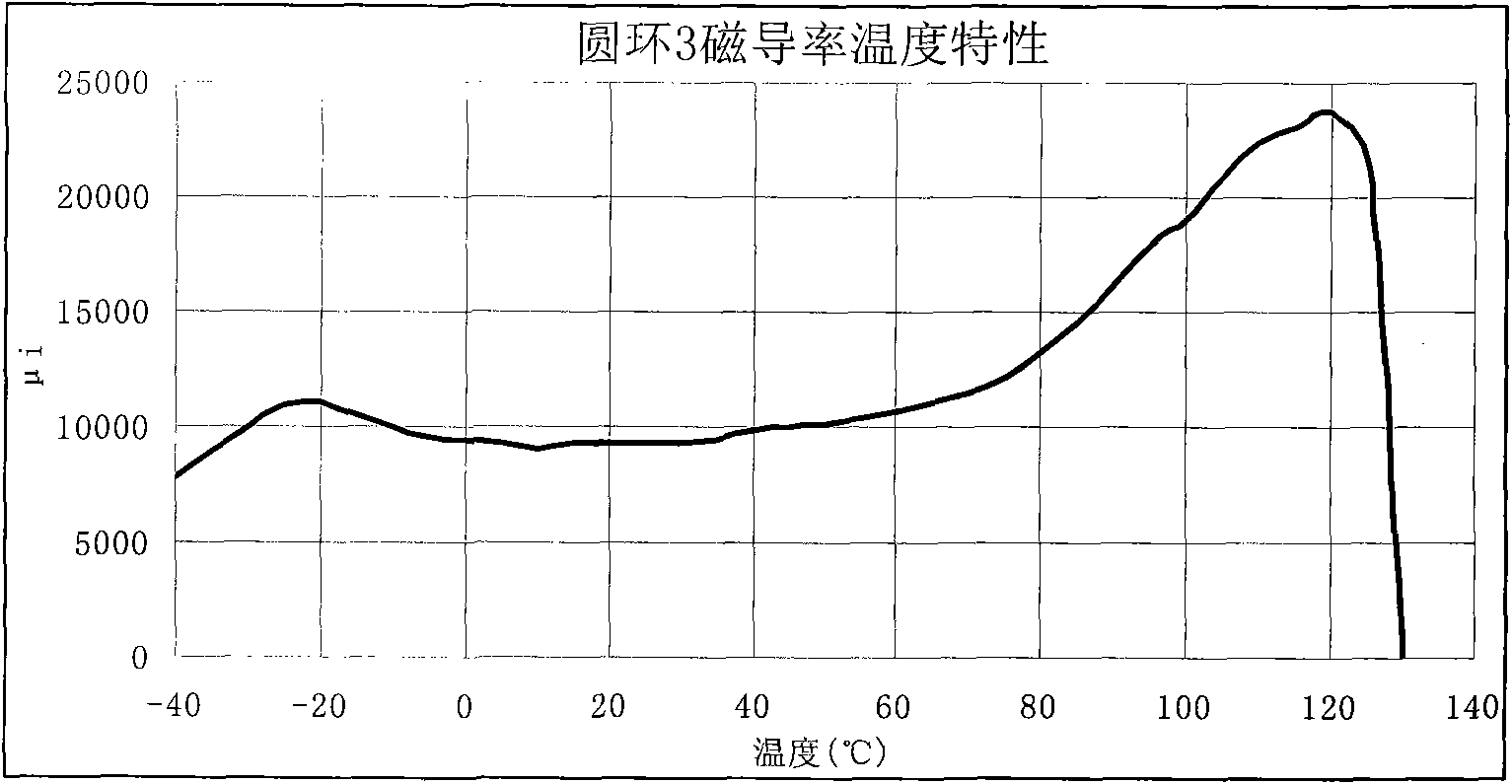

Embodiment 3

[0033] Press Fe 2 o 3 : MnO: ZnO = 52.5: 24.5: 23.0mol% of the formula for a batching, where Fe 2 o 3 Adopt Japanese Kawasaki iron red, purity ≥ 99.5wt%, MnO converted to Mn 3 o 4 , using high-purity Mn from Hunan Jinrui 3 o 4 , Mn purity ≥ 70.8wt%, ZnO adopts ZnO from Haimen, Zhejiang, with purity ≥ 99.7wt%. Pour the three raw materials into a mixing tank, add a dispersant and deionized water, fully stir and mix, and perform a ball mill for 4 to 6 hours. Spray drying and pre-calcination are carried out. The pre-calcination temperature is 860-960° C. and the pre-calcination time is 60-90 minutes to obtain a calcined material.

[0034] The pre-fired material is used for secondary batching, put into a ball mill for secondary ball milling, and three groups of auxiliary materials A, B, and C are added. The auxiliary material of group A is CaCO with a weight percentage of 100ppm 3 , the composition of the B group auxiliary material is MoO with a weight percentage of 100ppm ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com