Ferrite material

A technology of ferrite material and sintered body, applied in the direction of magnetic material, inorganic material magnetic, iron compound, etc., can solve the problem of not being able to have both the saturation magnetic flux density and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment

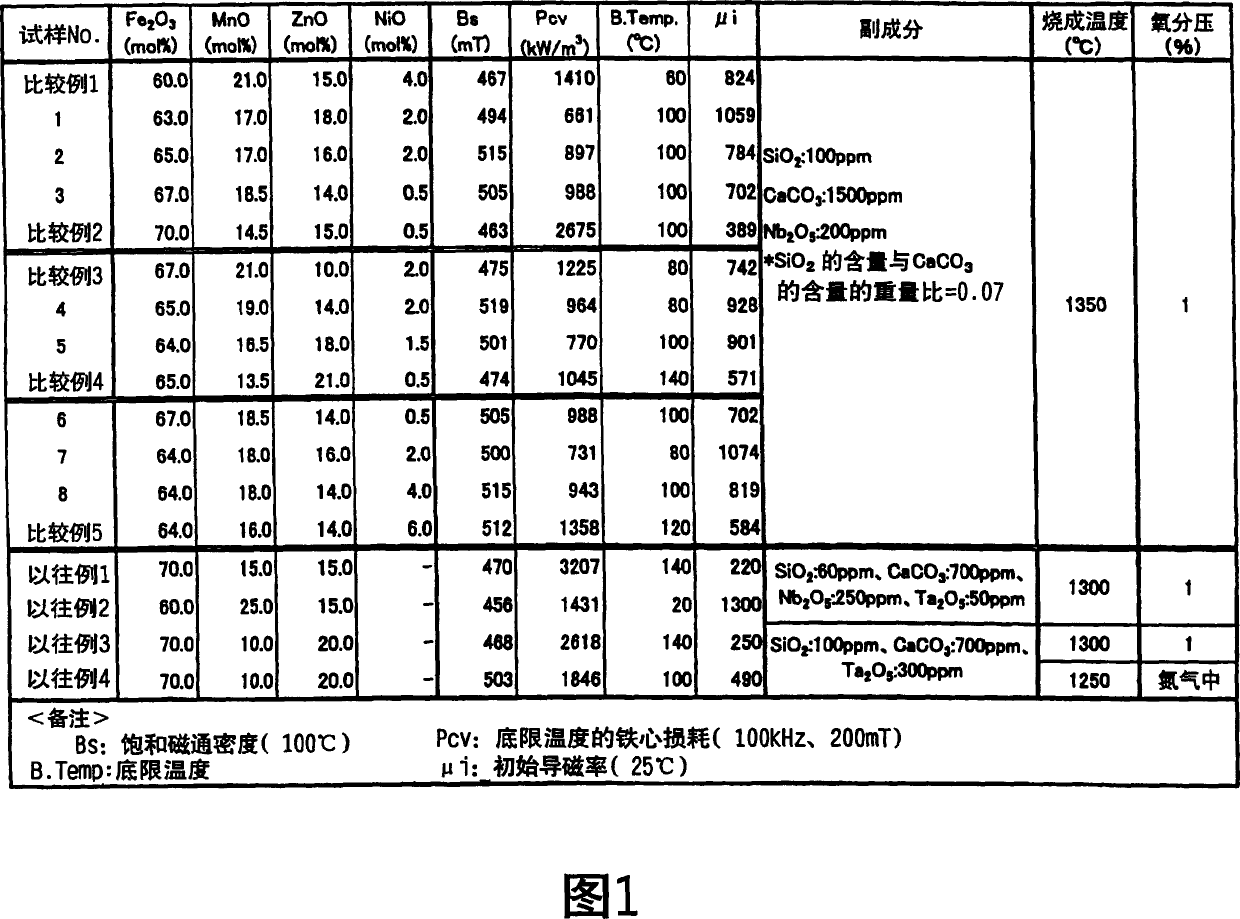

[0077] Experiments conducted to confirm a preferable composition of MnZnNi-based ferrite are shown as a first example.

[0078] A ferrite with the composition shown in Figure 1 was fabricated.

[0079] As the raw material of the main component, Fe is used 2 o 3 powder, MnO powder, ZnO powder and NiO powder. These powders were calcined at 900° C. for 2 hours after wet mixing.

[0080] Next, the calcined product of the raw material of the main component and the raw material of the subcomponent are mixed. SiO is used as a raw material for subcomponents 2 Powder, CaCO 3 powder and Nb 2 o 5 powder. The raw material of the subcomponent is added to the calcined product of the raw material of the main component, and mixed while pulverizing. Pulverization was performed until the average particle diameter of the calcined product became 1.5 μm. A binder was added to the obtained mixture, and it was granulated and molded to obtain a ring-shaped molded body.

[0081] The obtaine...

no. 2 Embodiment

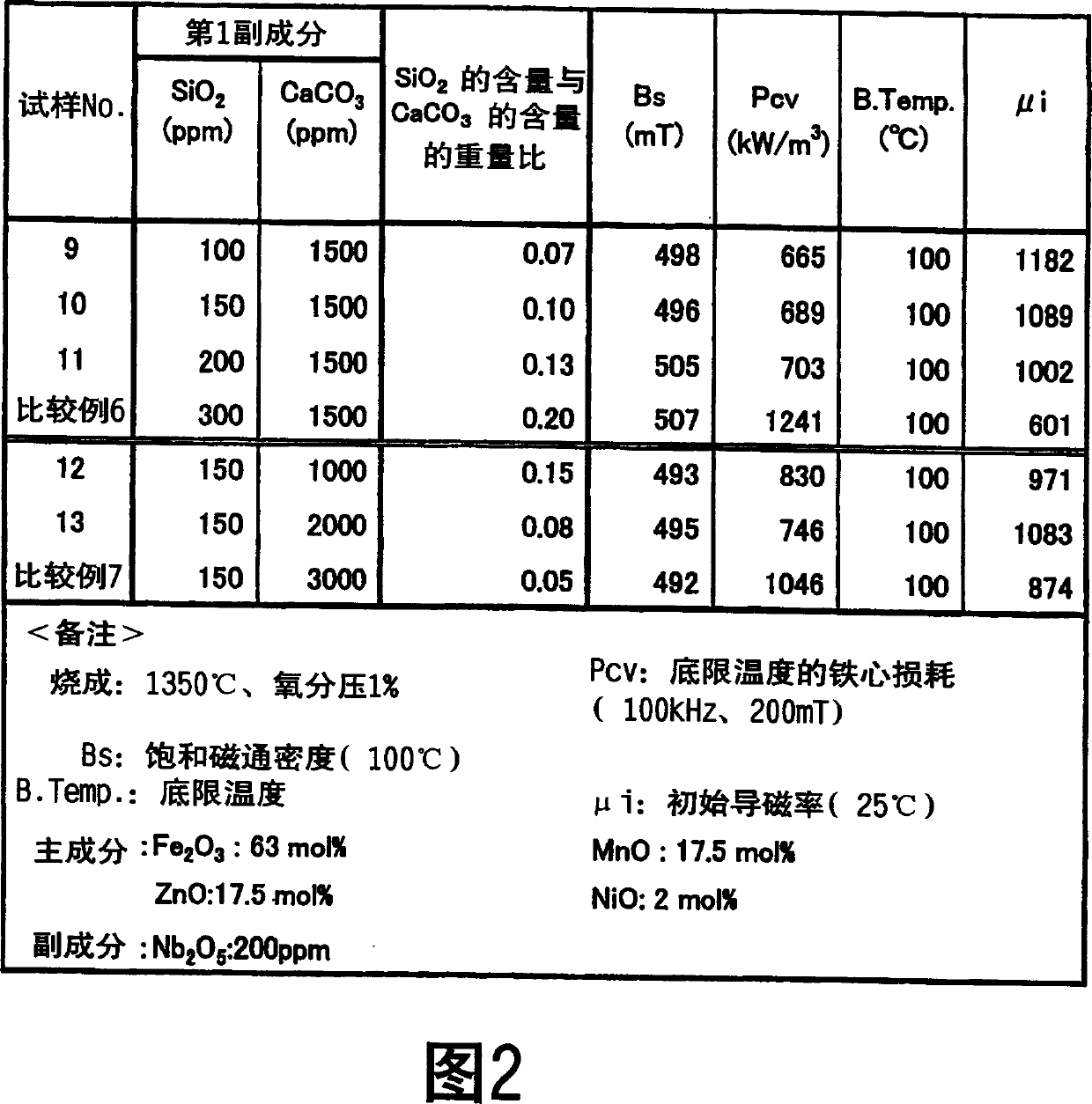

[0091] An experiment conducted to confirm the optimum addition amount of the first subcomponent for MnZnNi-based ferrite is shown as a second example.

[0092] A ferrite core having the composition shown in FIG. 2 was produced by the same process as in the first embodiment. In addition, magnetic properties and the like were measured under the same conditions as in the first example. The results are shown together in FIG. 2 .

[0093] As shown in FIG. 2 , it can be seen that the core loss (Pcv) can be reduced by adding Si and Ca as the first subcomponents in predetermined amounts. However, in the case of Si, the amount added is SiO 2 When converted to 300ppm, the core loss increases. On the other hand, in the case of Ca, its addition amount is expressed as CaCO 3 When converted into an additive amount of 3000 ppm, the core loss increases.

no. 3 Embodiment

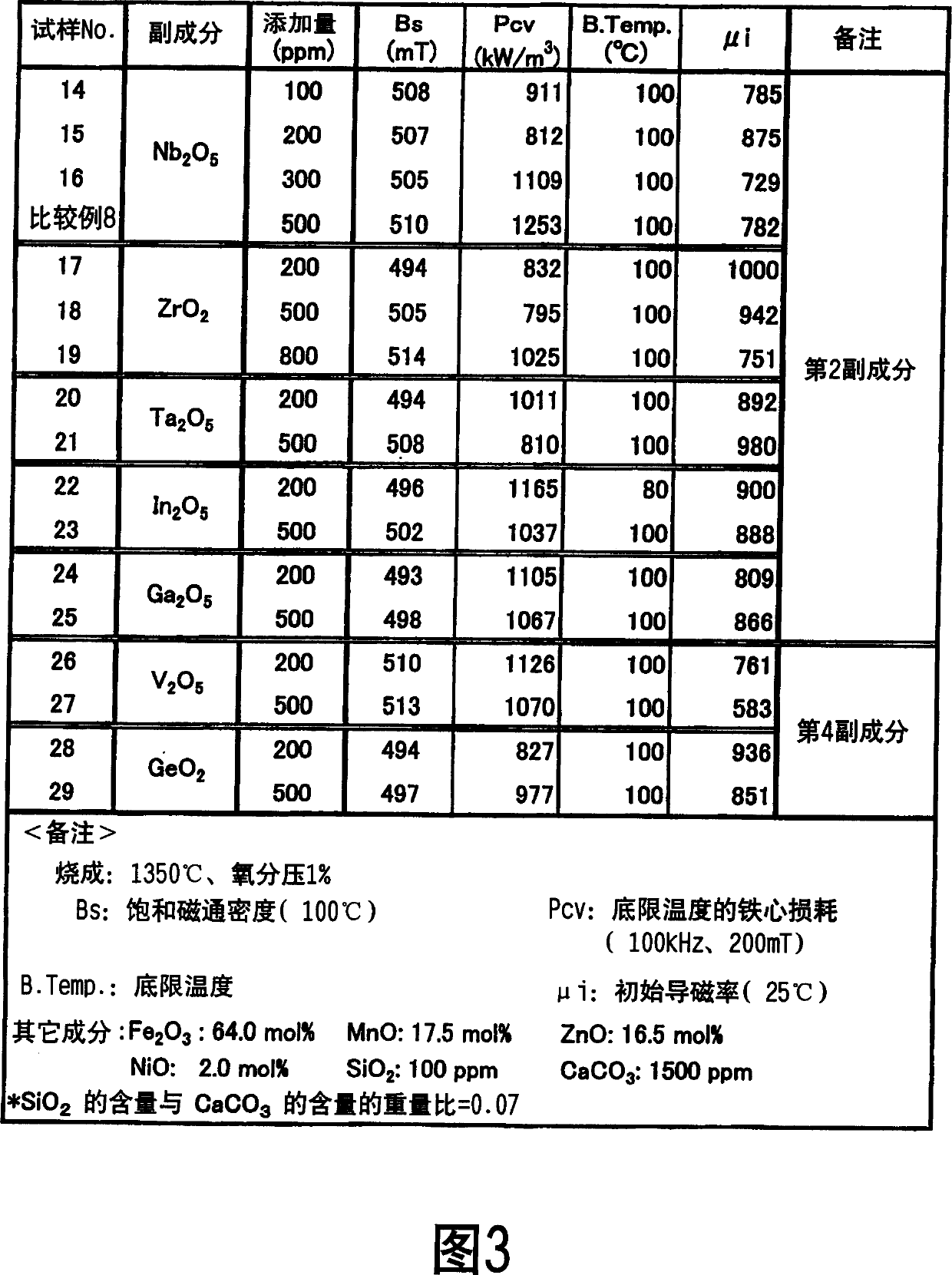

[0095] An experiment conducted to confirm changes in magnetic properties and the like associated with the addition of the second subcomponent or the fourth subcomponent for MnZnNi-based ferrite is shown as a third example.

[0096] A ferrite core having the composition shown in FIG. 3 was produced by the same process as in the first embodiment. In addition, magnetic properties and the like were measured under the same conditions as in the first example. The results are shown together in FIG. 3 .

[0097] As shown in Figure 3, it can be seen that even if the second subcomponent (Nb 2 o 5 , ZrO 2 、 Ta 2 o 5 、In 2 o 5 , Ga 2 o 5 ) or the fourth subcomponent (V 2 o 5 、GeO 2 ) still has a saturation magnetic flux density (Bs) of around 500mT, while obtaining 1200kW / m 3 or less core loss (Pcv). Nb in the second subcomponent 2 o 5 , ZrO 2 、 Ta 2 o 5 , and GeO in the fourth subcomponent 2 The effect of reducing the core loss is greater. For its Nb 2 o 5 In other...

PUM

| Property | Measurement | Unit |

|---|---|---|

| saturation flux density | aaaaa | aaaaa |

| saturation flux density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com