Iron-based amorphous soft magnetic alloy with high saturation magnetic induction and preparation method thereof

A magnetic induction strength, iron-based amorphous technology, applied in the direction of magnetic objects, magnetic materials, electrical components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

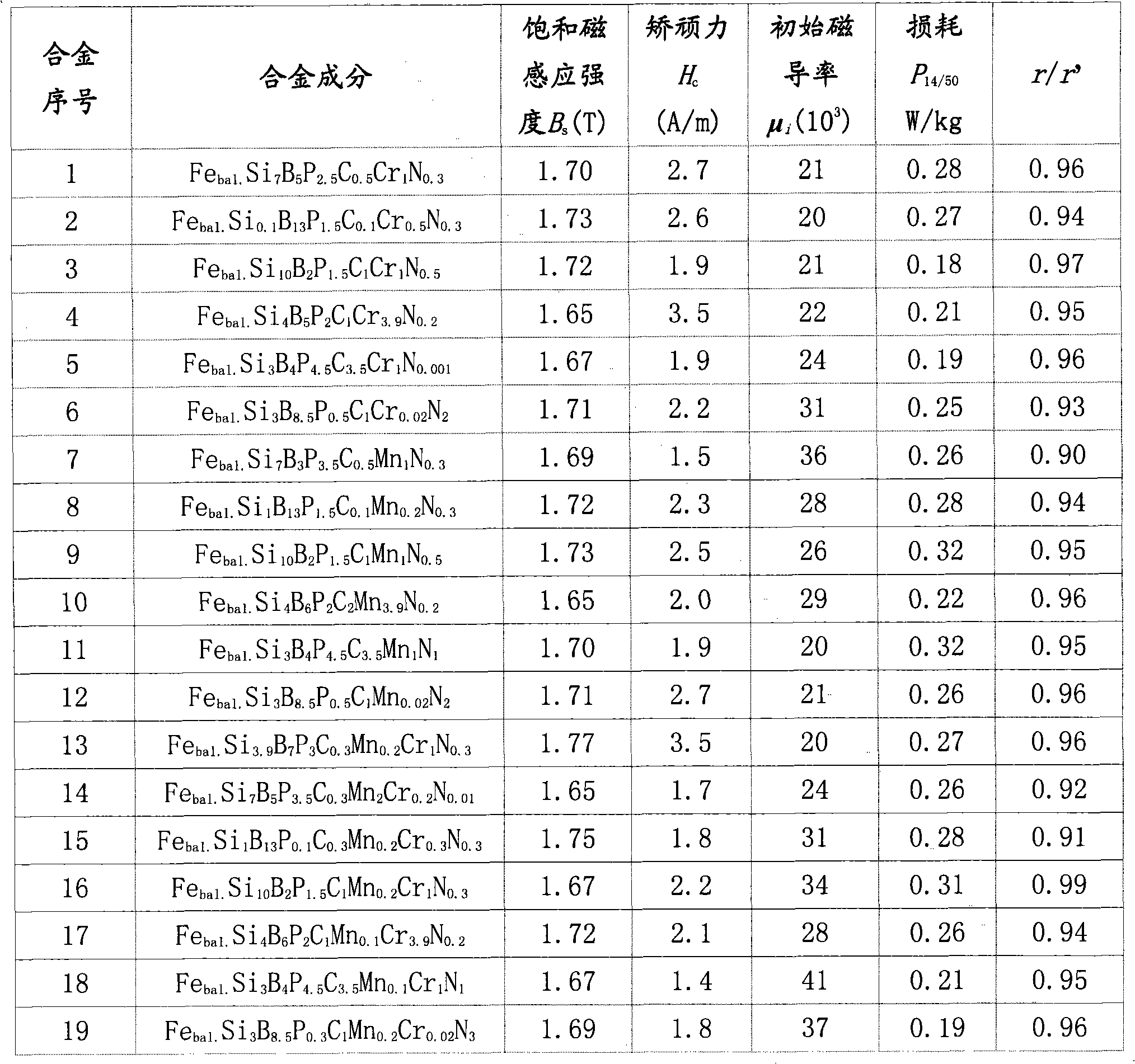

[0057] According to the composition range of the iron-based amorphous alloy of the present invention, we did a series of experiments. Dosing according to the composition of the present invention, at 1MPa N 2 The master alloy is smelted into ingots under pressure. Then at 0.5MPa N 2 Under protection, the master alloy ingot was heated to 1400°C, and an amorphous strip with a width of 10±0.1mm and a thickness of 28-30μm was prepared by a single-roll method at a roll speed of 25m / s. The thin strip was wound into a core having an outer diameter of 20 mm and an inner diameter of 16 mm. Under the protection of argon, the iron core was isothermally annealed at 380°C for 40 minutes, and the measured soft magnetic properties are listed in Table 1. The saturation magnetic induction of the alloy B s Vibrating sample magnetometer (VSM) is used to measure, and the magnetic induction intensity with a magnetic field of 10000A / m is used as the saturation magnetic induction intensity B of t...

Embodiment 2

[0066] According to the composition range of the iron-based amorphous alloy of the present invention, we did a series of experiments. Carry out batching according to the alloy composition of the present invention, in the N of 2MPa 2 Master alloy smelting under pressure. Then at 0.35MPa N 2 Under protection, the master alloy ingot was smelted to 1400°C, and an amorphous strip with a width of 10±0.1mm and a thickness of 28-30μm was prepared by a single-roll method at a roll speed of 26m / s. The thin strip was wound into a core having an outer diameter of 20 mm and an inner diameter of 16 mm. Under the protection of argon, the iron core was isothermally annealed at 380°C for 30 minutes, and the measured soft magnetic performance indicators are shown in Table 1. The saturation magnetic induction of the alloy B s Vibrating sample magnetometer (VSM) is used to measure, and the magnetic induction intensity with a magnetic field of 10000A / m is used as the saturation magnetic induct...

PUM

| Property | Measurement | Unit |

|---|---|---|

| saturation magnetic induction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com