Iron-based constant-permeability nano crystal magnetic core and production method thereof

A nanocrystalline and magnetic core technology, which is applied in the manufacture of inductors/transformers/magnets, magnetic materials, magnetic objects, etc., can solve problems affecting the continuous preparation of strips, insufficient fluidity of molten steel, and high brittleness of strips, etc., to achieve Simple and fast production process, low coercive force, strong corrosion resistance and thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

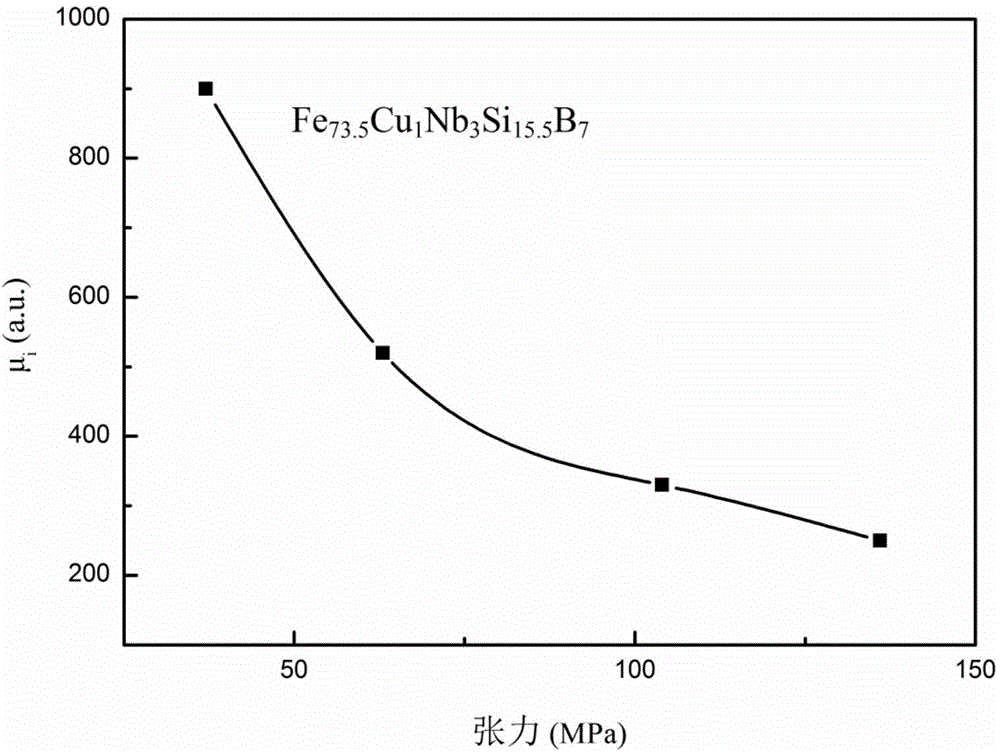

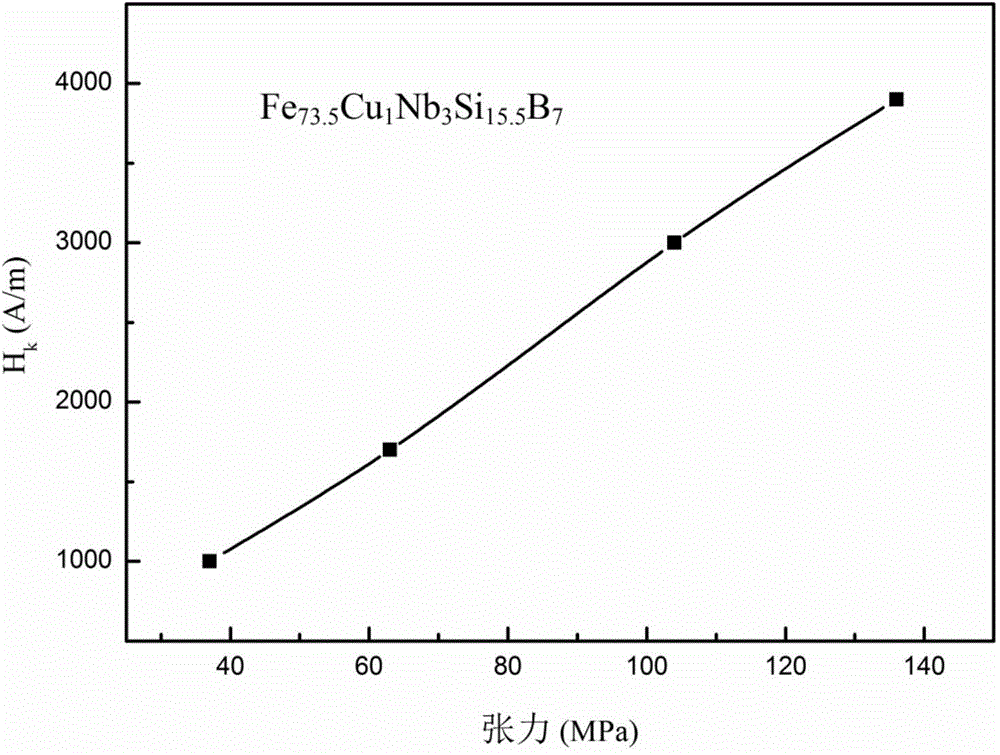

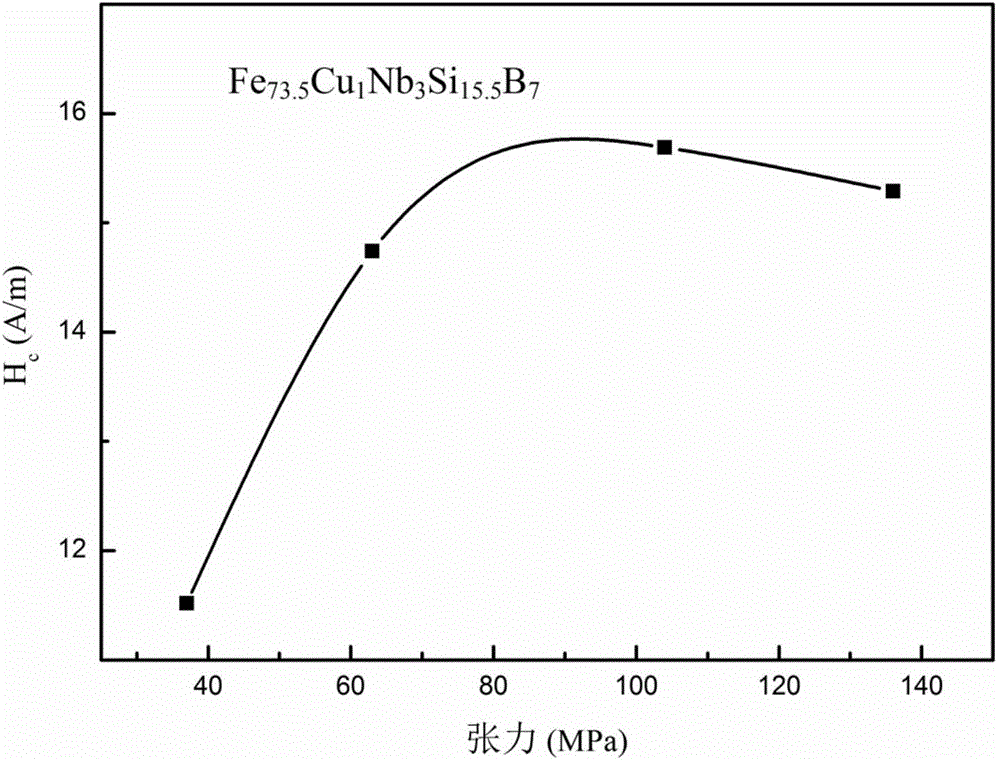

[0061] Embodiment 1 is used to prepare the alloy of magnetic core to be Fe 73.5 Cu 1 Nb 3 Si 15.5 B 7

[0062] In this embodiment, 6 groups of tests were carried out, wherein the first four groups (1-4) were products of the present invention, and the latter two groups (5-6) were comparative examples.

[0063] The preparation method is as follows:

[0064](1) According to the composition and raw material ratio of each experimental combination of gold in Table 1, the alloy raw materials were vacuum smelted at 1350 ° C to prepare a master alloy ingot; then the master alloy ingot was put into a vacuum induction furnace for secondary melting Then under the protection of argon, while maintaining the constant pressure in the furnace, the quenched amorphous alloy thin strip with a width of 30 mm and a thickness of 22 μm is made by using a single roll quenching method, wherein the roll is a copper roll, and the surface speed of the roll is 25 m / s;

[0065] (2) Cut the thin stri...

Embodiment 2

[0078] Each group of magnetic cores in Example 1 is made into a current transformer through processes such as surface treatment, packaging, copper wire winding, and testing. The performance parameters of the obtained current transformers are shown in Table 2. The relative error RE and phase difference θ in the table are tested by the transformer calibrator, and the rated primary current of the test is 60A.

[0079] Table 2 Alloy heat treatment method and performance data of current transformer

[0080]

[0081] Magnetic core provided by the present invention can be used for current transformer, see Figure 10 , which is an equivalent circuit diagram of a known current transformer. The current transformer includes the magnetic core provided by the present invention, and additionally has a primary winding and at least one secondary winding. The primary winding usually has one turn. As can be seen from Table 2, the current transformer of the present invention has a small abs...

Embodiment 3

[0083] Each group of magnetic cores in Example 1 is made into a current compensation choke coil through processes such as surface treatment, packaging, copper wire winding, and testing. The performance parameters of the obtained current transformers are shown in Table 3.

[0084] Table 3 Alloy heat treatment method and performance data of current compensation choke coil

[0085]

[0086] The magnetic core provided by the present invention can be used for current compensation choke coil, see Figure 11 , which is a working principle diagram of the known current compensation choke coil. The current compensation choke coil of the present invention has the above-mentioned magnetic core. Phase or multi-phase current has more than three windings with the same turns and the same direction. The current compensation choke coil provided by the invention has strong anti-saturation capability, and the loss value is less than 50W / kg under the condition of 500mT / 20kHz.

[0087] Based ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com