High voltage induction energy fetching power supply and method for obtaining power from high voltage line

A technology of energy extraction and high-voltage induction, applied in circuits, transformers, inductors, etc., can solve the problems of low conversion efficiency of solar cells, limited energy, and restricted applications.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

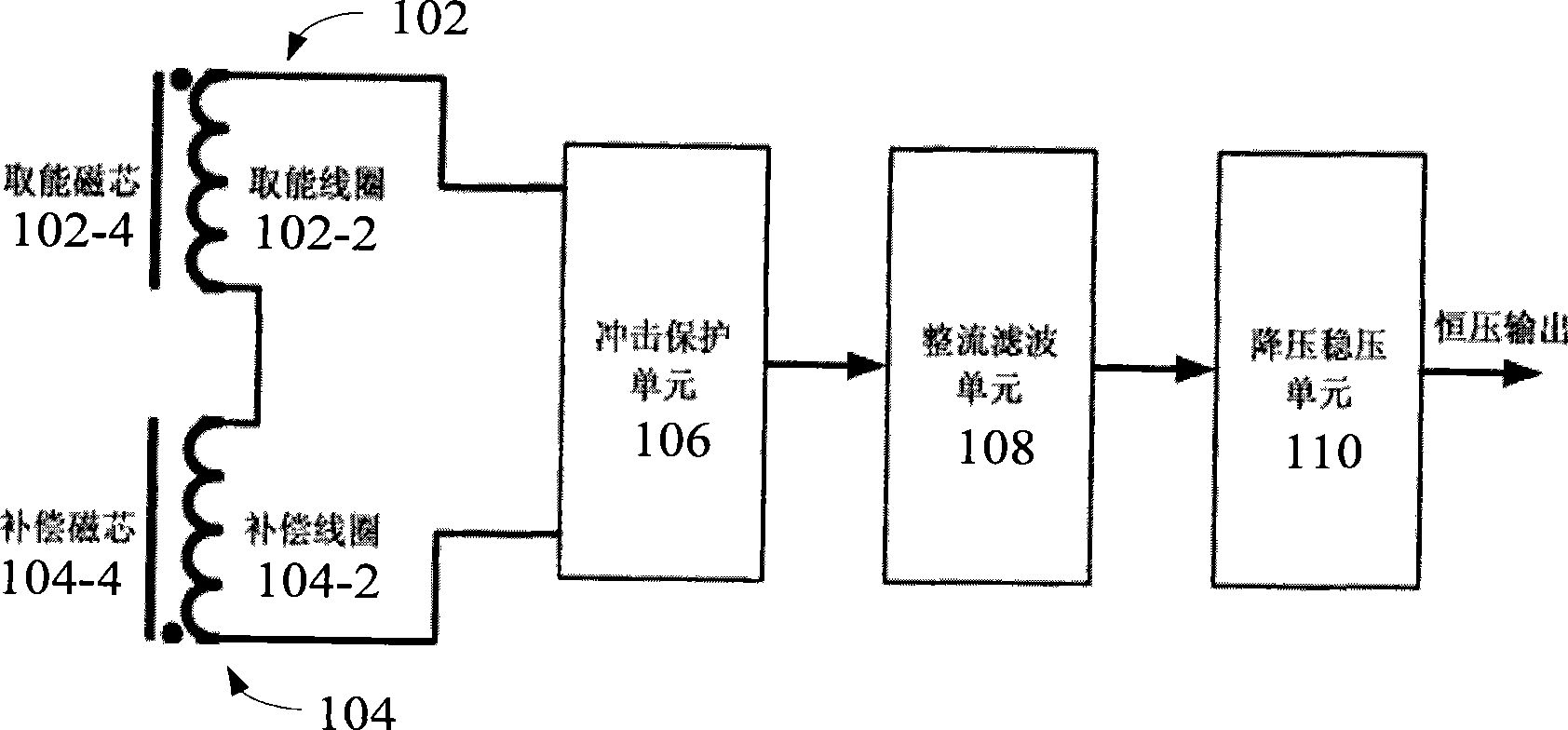

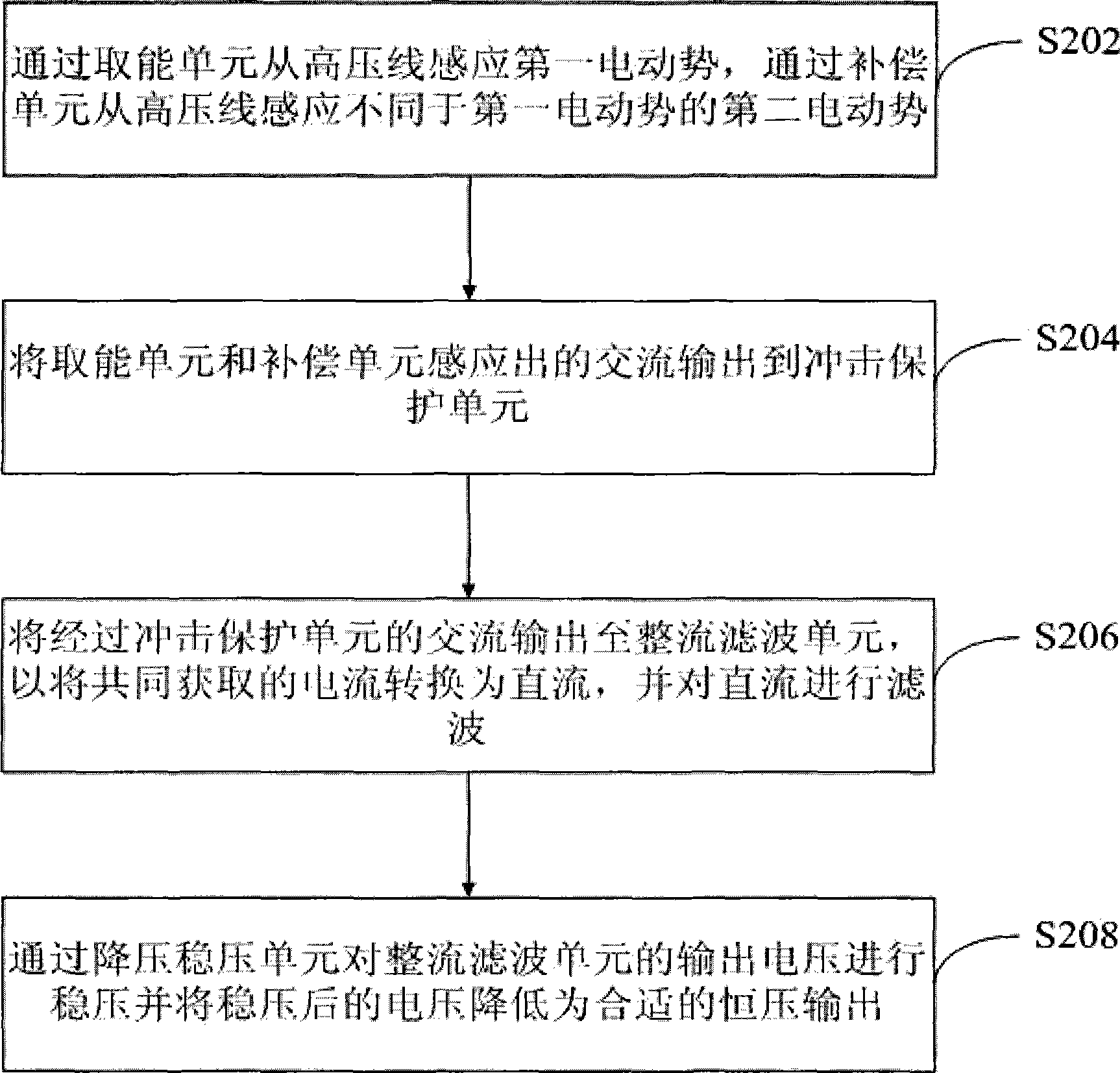

[0025] The specific implementation manners of the present invention will be described in detail below with reference to the accompanying drawings.

[0026] Line current induction energy harvesting The energy for power supply comes from the high-voltage line, and the energy harvesting is completed through a magnetic ring wound with a coil and worn on the high-voltage line. At present, the problems that need to be solved urgently in this power supply method include: 1) providing stable output under the condition of wide range variation of line current; 2) long-term stable operation with low heat consumption.

[0027] In recent years, there have been many reports at home and abroad on the research on line current sensing energy harvesting and power supply. It is required that the high-voltage side electronic equipment can work under the condition that the current of the high-voltage line is small. The energy-taking magnetic core can be made by selecting magnetic materials with hi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com