Nanocrystalline spinel-carbon composite powder and preparation method thereof

A technology of carbon composite powder and spinel, which is applied in the field of nanocrystalline spinel-carbon composite powder and its preparation, can solve problems such as unevenness and excessive dispersion of spinel grains, and achieve good interface bonding , avoid the effect of excessive grain size and clean interface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

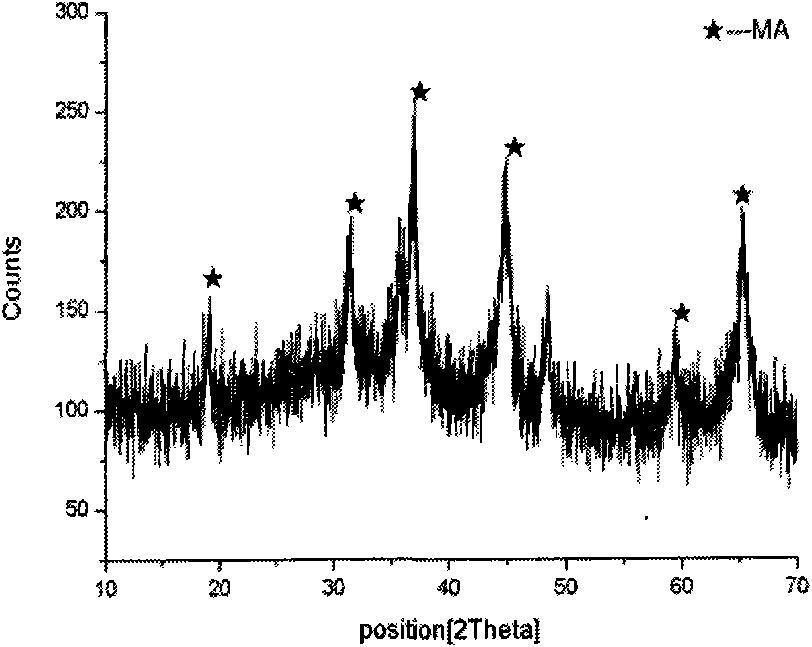

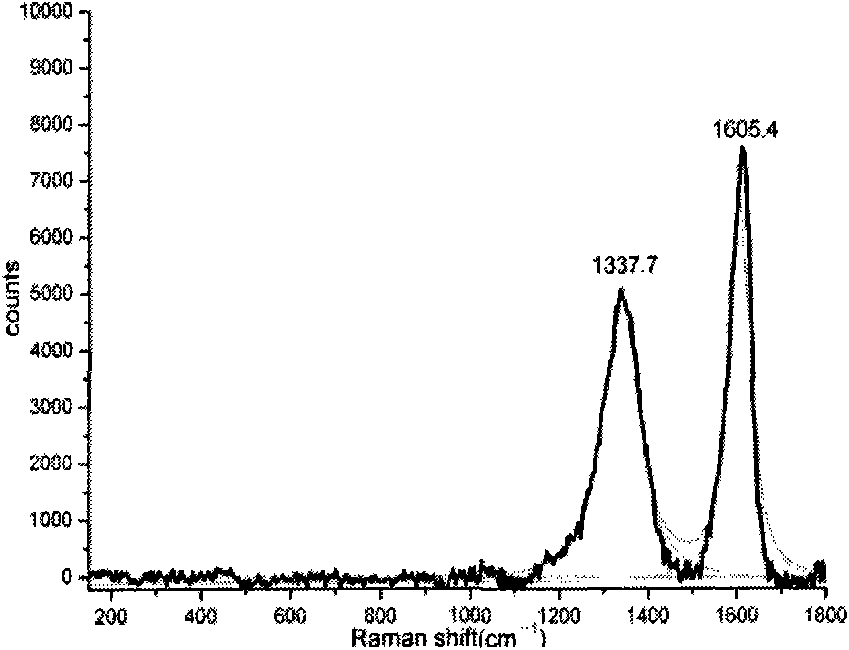

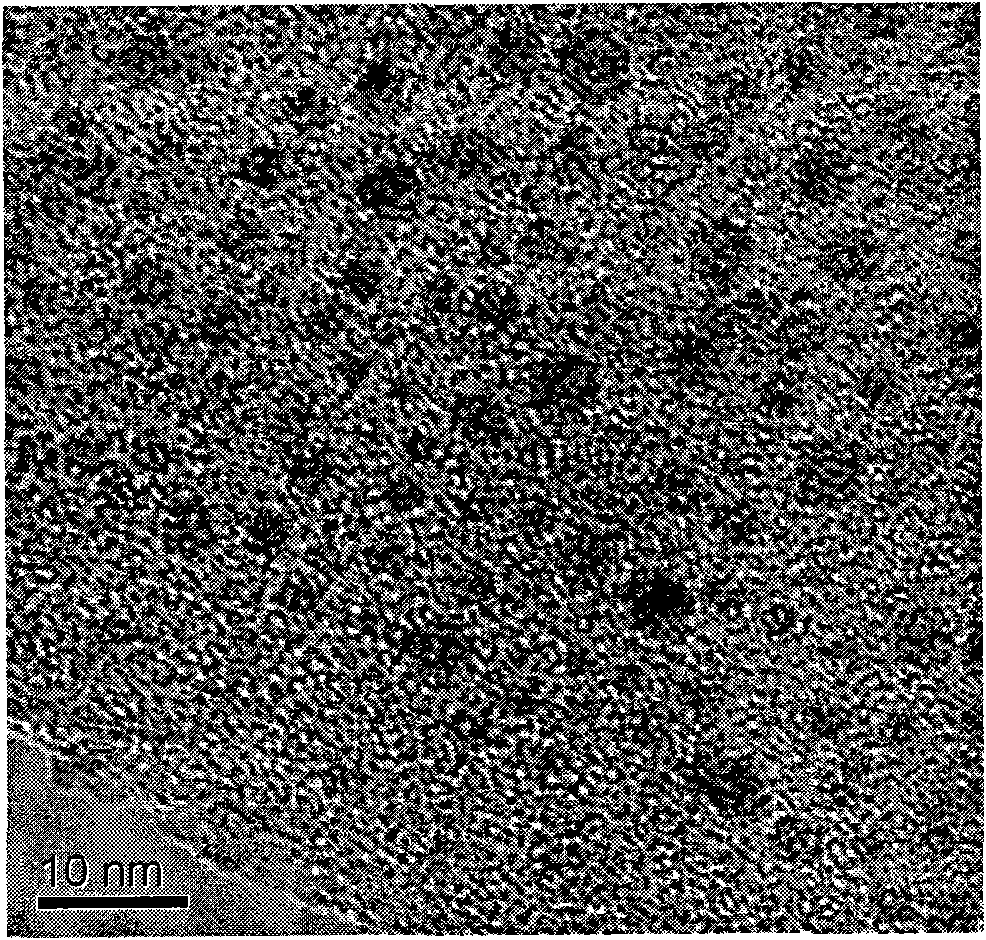

[0023] A nanocrystalline spinel-carbon composite powder and a preparation method thereof. Using magnesite and metal aluminum powder as raw materials, mixing magnesite and metal aluminum powder at a molar ratio of 3:4 to form a mixed raw material. Then put the mixed raw material and steel ball into the stainless steel ball mill jar according to the mass ratio of mixed raw material and steel ball as 1: (40-60), seal it, vacuumize it to -0.1MPa, and then place it on a planetary ball mill for ball milling for 2-2 ~ After 50 hours, a nanocrystalline spinel-carbon composite powder was prepared.

Embodiment 2

[0025] A nanocrystalline spinel-carbon composite powder and a preparation method thereof. The industrial magnesium carbonate and metal aluminum powder are used as raw materials, and the industrial magnesium carbonate and metal aluminum powder are mixed at a molar ratio of 3:4 to form a mixed raw material. Then put the mixed raw material and steel ball into a stainless steel ball mill tank according to the mass ratio of mixed raw material and steel ball as 1: (40-60), seal it, vacuumize it to -0.1MPa, fill it with high-purity nitrogen, and place it on a planetary Milling on a ball mill for 2 to 50 hours to prepare nano crystal spinel-carbon composite powder.

Embodiment 3

[0027] A nanocrystalline spinel-carbon composite powder and a preparation method thereof. Using chemically pure magnesium carbonate and metal aluminum powder as raw materials, chemically pure magnesium carbonate and metal aluminum powder are mixed in a molar ratio of 3:4 to form a mixed raw material, and metal nickel powder less than 0.1wt% of the mixed raw material is added, and mixed evenly , forming a mixture. Then put the mixture and steel balls into a stainless steel ball mill tank according to the mass ratio of the mixture to steel balls is 1: (40-60) and seal it, vacuumize to -0.1MPa, fill with high-purity argon, and then place Milling on a planetary ball mill for 2 to 50 hours to prepare nano crystal spinel-carbon composite powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com