Preparation method for diamond/copper composite material with high heat conductivity and low thermal expansion coefficient

A low thermal expansion coefficient and composite material technology, applied in the field of metal matrix composite materials, can solve the problem of low thermal conductivity of composite materials, achieve good interface bonding, high density, and reduce thermal expansion coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

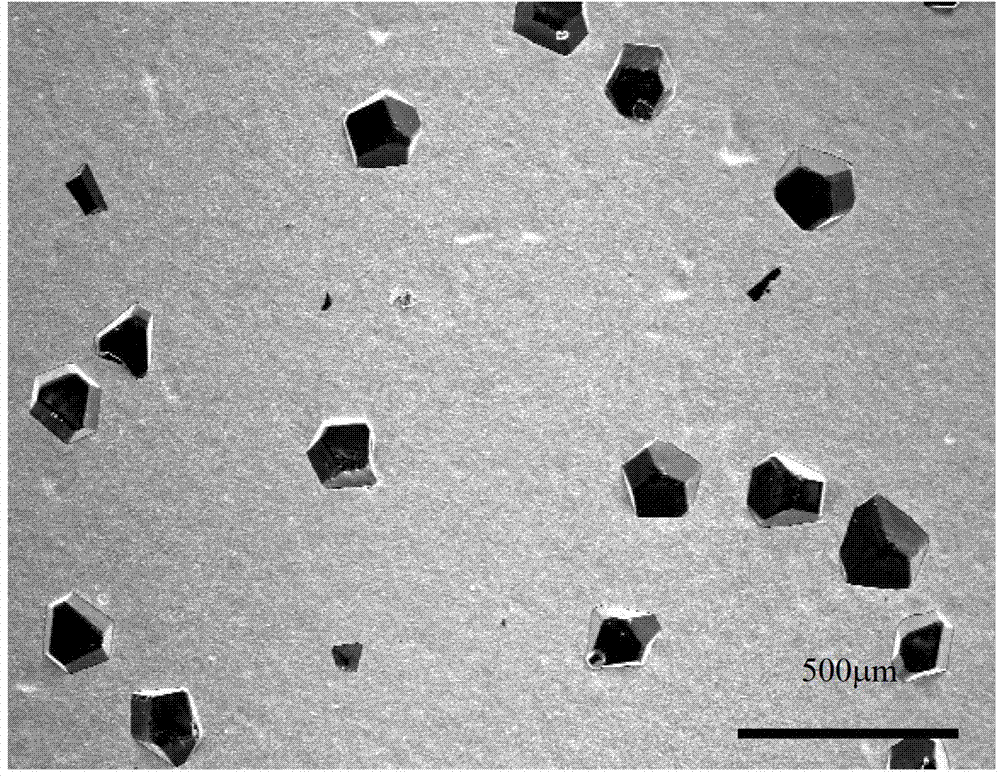

[0014] Specific Embodiment 1: In this embodiment, a method for preparing a diamond / copper composite material with high thermal conductivity and low thermal expansion coefficient is realized according to the following steps:

[0015] 1. Copper-coated diamond powder is formed by electroless copper plating on the surface of diamond powder with a particle size of 1-200 μm to coat a copper coating of 0.1-5 μm;

[0016] 2. Mix the copper-plated diamond powder and copper powder in step 1 by mechanical powder mixing to form a mixed powder;

[0017] 3. Use a graphite mold to cold-press the mixed powder prepared in step 2, then put the cold-pressed mixed powder together with the graphite mold into a vacuum hot-press furnace, and first evacuate the vacuum hot-press furnace to a vacuum degree of 0.001 ~0.1Pa, and then under the condition of heating rate of 5~20℃ / min, the temperature of the vacuum hot-press furnace is raised to 800~1000℃, and the pressure is applied to 20~60MPa at the same...

specific Embodiment approach 2

[0021] Embodiment 2: This embodiment differs from Embodiment 1 in that: the particle size of the diamond powder in step 1 is 50-150 μm. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0022] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the particle size of the diamond powder in step 1 is 100 μm. Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com