Brazing method and solder preparation method for high-volume-fraction SiCp/Al composite

A high volume fraction, composite material technology, applied in the direction of welding/cutting media/materials, welding equipment, welding media, etc., can solve the problems of poor wettability, low air tightness, low strength of brazed joints, etc., and achieve joint strength High, well-integrated interface, tight connection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

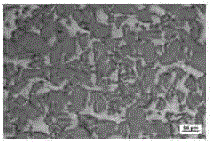

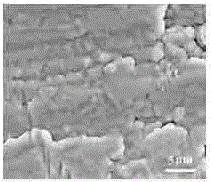

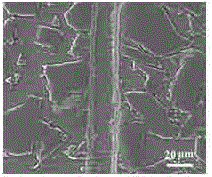

Image

Examples

Embodiment 1

[0024] A method for preparing brazing material of high volume fraction SiCp / Al composite material, comprising the steps of:

[0025] The first step, mixing materials: according to the mass ratio of 26.7%Cu, 5.25%Si, 1.5%Mg and the balance of Al, the raw materials of pure Al, pure Cu, Al-20Si, Al-50Mg are mixed, and then pure Al, The Cu element and the Al-20Si master alloy are placed in the graphite crucible of the high vacuum induction melting furnace, and the Al-50Mg master alloy is placed in the stainless steel mold, and the stainless steel mold is evacuated to 1×10 -3 Pa~3×10 -3 Pa, and then filled with high-purity argon until the pressure in the stainless steel mold is 0MPa;

[0026] The second step is to prepare the brazing material blank: turn on the induction heating power supply, preheat the graphite crucible to 300 ° C ~ 400 ° C, and then heat the graphite crucible to 1500 ° C ~ 1600 ° C within 10 minutes to completely melt the metal raw materials in the graphite cru...

Embodiment 2

[0036] A method for preparing brazing material of high volume fraction SiCp / Al composite material, comprising the steps of:

[0037] The first step, mixing materials: according to the mass ratio of 20.0%Cu, 6.0%Si, 1.5%Mg and the balance of Al, the raw materials of pure Al, pure Cu, Al-20Si, Al-50Mg are mixed, and then pure Al, The Cu element and the Al-20Si master alloy are placed in the graphite crucible of the high vacuum induction melting furnace, and the Al-50Mg master alloy is placed in the stainless steel mold, and the stainless steel mold is evacuated to 1×10 -3 Pa~3×10 -3 Pa, and then filled with high-purity argon until the pressure in the stainless steel mold is 0MPa;

[0038] The second step is to prepare the brazing material blank: turn on the induction heating power supply, preheat the graphite crucible to 300 ° C ~ 400 ° C, and then heat the graphite crucible to 1500 ° C ~ 1600 ° C within 10 minutes to completely melt the metal raw materials in the graphite cruc...

Embodiment 3

[0048] A method for preparing brazing material of high volume fraction SiCp / Al composite material, comprising the steps of:

[0049] The first step, mixing materials: according to the mass ratio of 28% Cu, 6% Si, 2% Mg and the balance Al, the raw materials of pure Al, pure Cu, Al-20Si, Al-50Mg are mixed, and then pure Al, The Cu element and the Al-20Si master alloy are placed in the graphite crucible of the high vacuum induction melting furnace, and the Al-50Mg master alloy is placed in the stainless steel mold, and the stainless steel mold is evacuated to 1×10 -3 Pa~3×10 -3 Pa, and then filled with high-purity argon until the pressure in the stainless steel mold is 0MPa;

[0050] The second step is to prepare the brazing material blank, turn on the induction heating power supply, preheat the graphite crucible to 300 ℃ ~ 400 ℃, and then heat the graphite crucible to 1500 ℃ ~ 1600 ℃ within 10 minutes to completely melt the metal raw materials in the graphite crucible , and ke...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shear strength | aaaaa | aaaaa |

| Shear strength | aaaaa | aaaaa |

| Shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com