Carbon nanotube metal based composite materials and process for preparing the same

A carbon nanotube and composite material technology, applied in the field of carbon nanotube composite materials and their preparation, can solve the problems of low strength of composite materials, and achieve the effects of light impact resistance, excellent performance and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

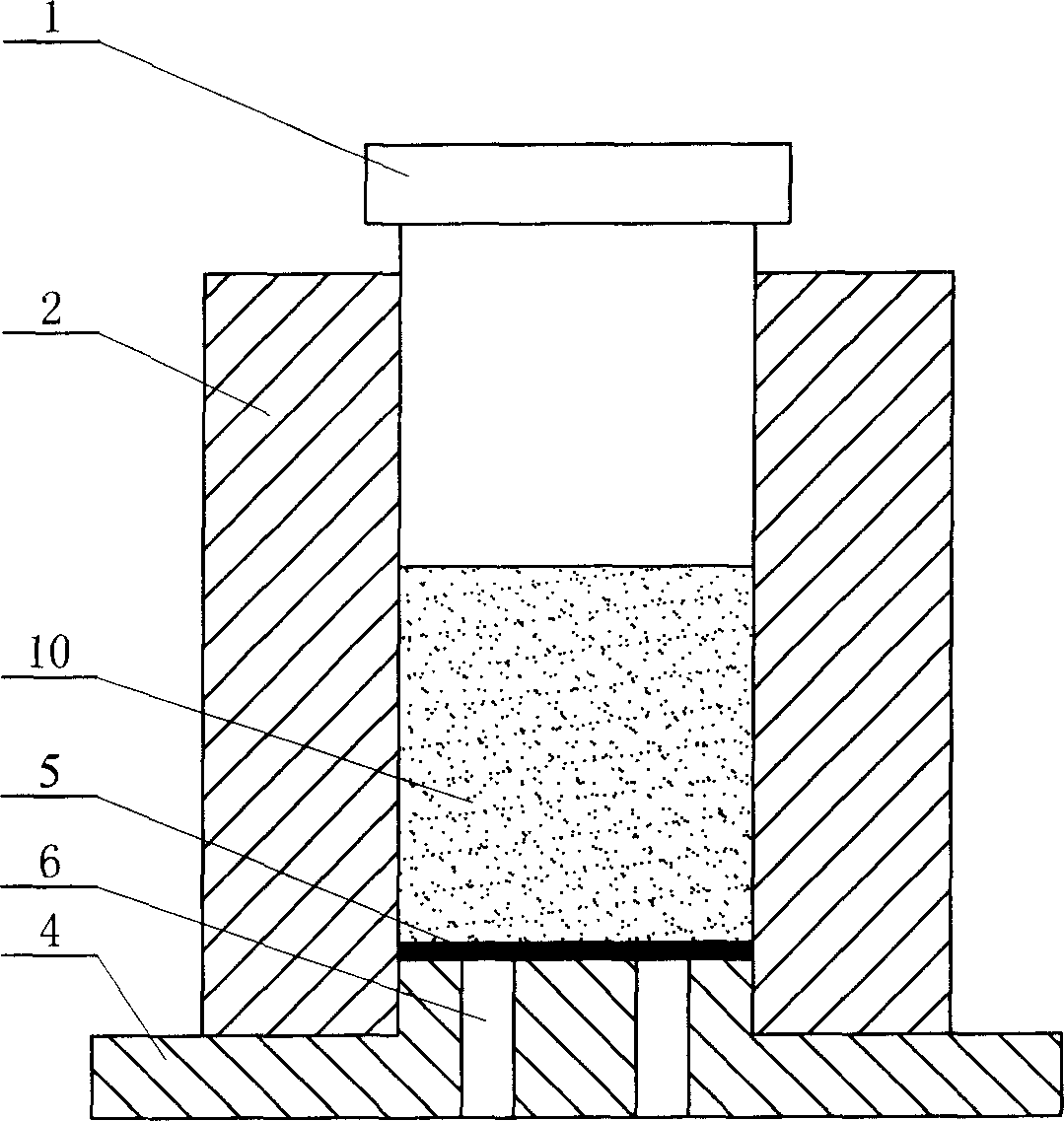

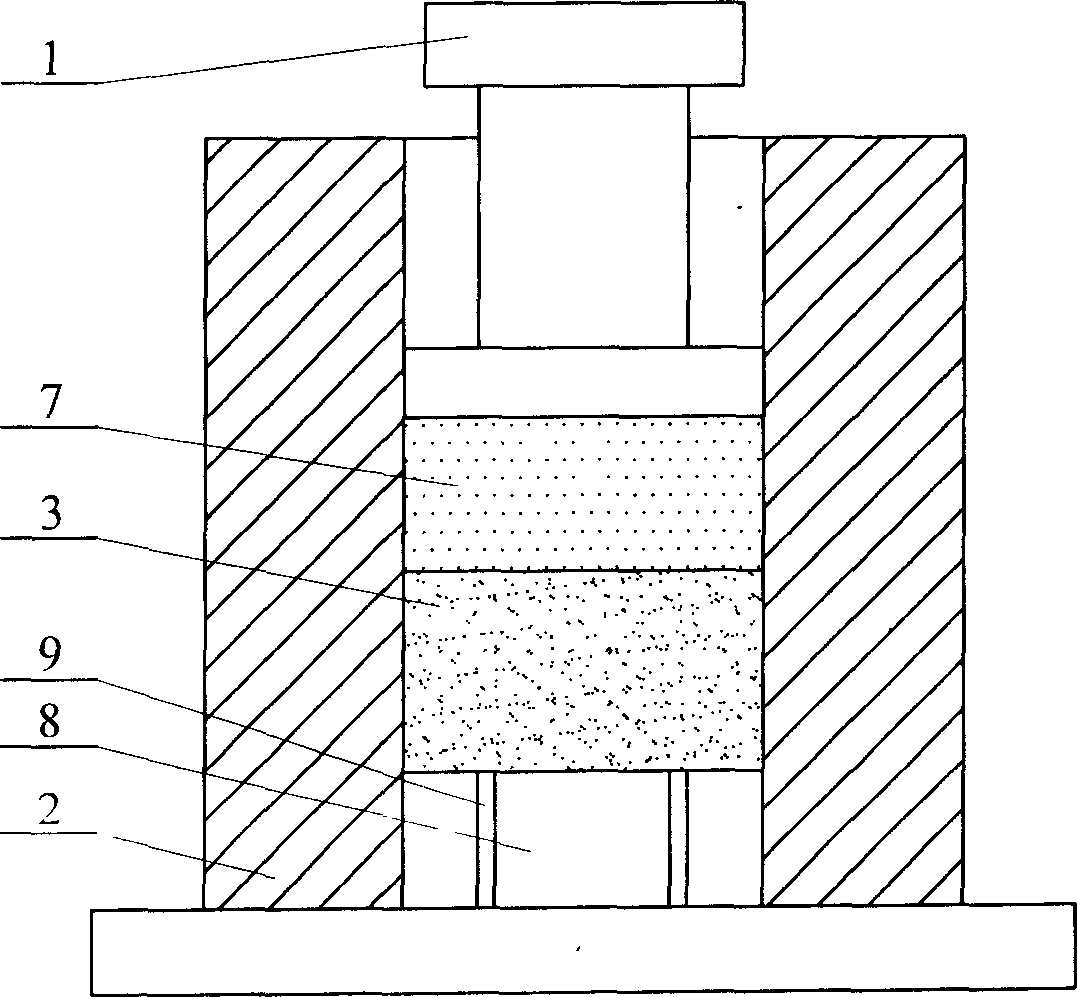

Method used

Image

Examples

specific Embodiment approach 1

[0016] Embodiment 1: The carbon nanotube metal matrix composite material of this embodiment is made of carbon nanotubes and metals, and the volume fraction of carbon nanotubes is 5 to 20%, and the metal (the metal adopts aluminum or aluminum alloy) is 20 to 95%. %.

[0017] The experimental results all show that carbon nanotubes have excellent mechanical properties. The reason why carbon nanotubes have such high strength and toughness is mainly due to the short distance between carbon atoms in carbon nanotubes, the small diameter of single-layer carbon nanotubes, and its nearly perfect structure, making it difficult to reveal defects. In addition, carbon nanotubes have similar wear resistance and friction reduction properties and self-lubricating properties to graphite. In addition, carbon nanotubes prepared by pyrolyzing hydrocarbon gas with catalysts are thin and curved, and are easier to infiltrate and pin in the matrix. Therefore, carbon nanotubes are ideal materials for...

specific Embodiment approach 2

[0018] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the carbon nanotube metal matrix composite material is made of 5% carbon nanotubes and 95% aluminum base in terms of volume fraction.

specific Embodiment approach 3

[0019] Embodiment 3: The difference between this embodiment and Embodiment 1 is that the carbon nanotube metal matrix composite material is made of 14% carbon nanotubes and 86% aluminum base in terms of volume fraction.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com