Method for preparing rGO-loaded petal-shaped MoS2 heterostructure

A heterostructure, petal-shaped technology, applied in the field of preparation of rGO-supported petal-shaped MoS2 heterostructures, can solve the problems of unfavorable photocatalytic efficiency, inability to effectively inhibit the recombination of photogenerated electrons and holes, and achieve enhanced light absorption and photocatalysis. Performance, good interfacial bonding, effect of increasing catalytic sites

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The present invention uses a one-step hydrothermal method to prepare rGO-loaded petal-like MoS 2 Composite structure; MoS under vacuum or argon atmosphere 2 / rGO composite structure powder is annealed to further improve its crystallinity; adjust the type of precursor, the amount of graphene oxide added and the reaction time during the reaction process to achieve the MoS 2 Alteration and control of cluster geometry. MoS of the present invention 2 The preparation method of / rGO heterostructure comprises the following steps:

[0028] (1) Sodium molybdate dihydrate and thiourea are selected as reactants, and graphene oxide is used as a precursor, and the mixed solution is fully mixed to uniformly disperse the suspended mixture.

[0029] The molar ratio of sodium molybdate dihydrate and thiourea is 1:5, the amount of graphene oxide added is controlled within the range of 0% to 10% of sodium molybdate dihydrate, and the above reactants are added to 60mL deionized water to o...

Embodiment 1

[0037] Sodium molybdate dihydrate and thiourea were used as reactants, the molar ratio of sodium molybdate dihydrate and thiourea was 1:5, graphene oxide was used as precursor, graphene oxide was not added, and MoS was synthesized by hydrothermal reaction 2 clusters. The hydrothermal reaction temperature is 210°C, and the reaction time is 24h. The annealing treatment was carried out under the condition of Ar atmosphere, the annealing temperature was 450°C, the heating rate was 5°C / min, the holding time was 2h, and the furnace was cooled.

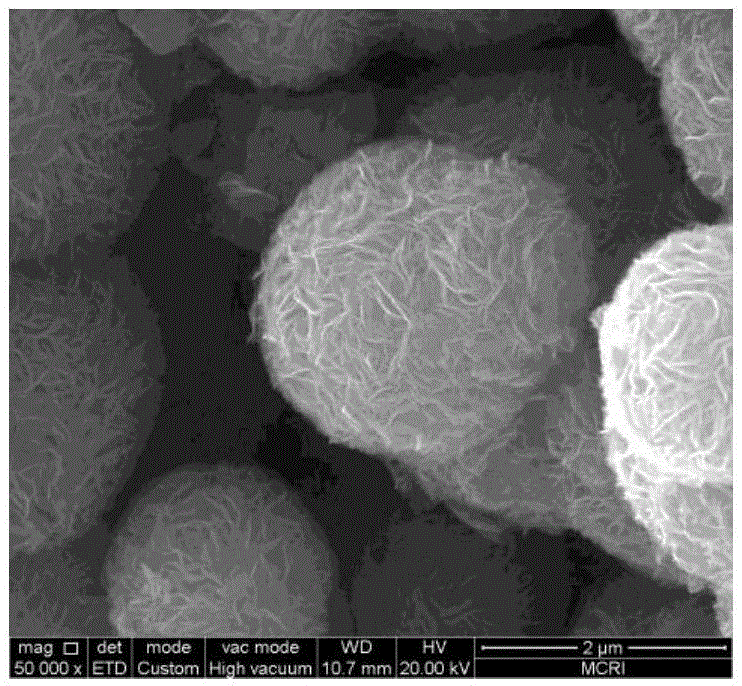

[0038] Such as figure 1 As shown, the MoS prepared in this example 2 The diameter of the cluster is 2.34 μm, and some MoS can be clearly seen on the surface of the cluster 2 Lamellar, poor dispersion of clusters.

Embodiment 2

[0040] Using sodium molybdate dihydrate and thiourea as reactants, the molar ratio of sodium molybdate dihydrate and thiourea is 1:5, graphene oxide is the precursor, and the amount of graphene oxide added is 1% of sodium molybdate dihydrate. %, MoS synthesized by hydrothermal reaction 2 / rGO composites. The hydrothermal reaction temperature is 210°C, and the reaction time is 24h. Annealing treatment under Ar atmosphere, the annealing temperature is 450°C, the heating rate is 5°C / min, the holding time is 2h, and it is cooled with the furnace.

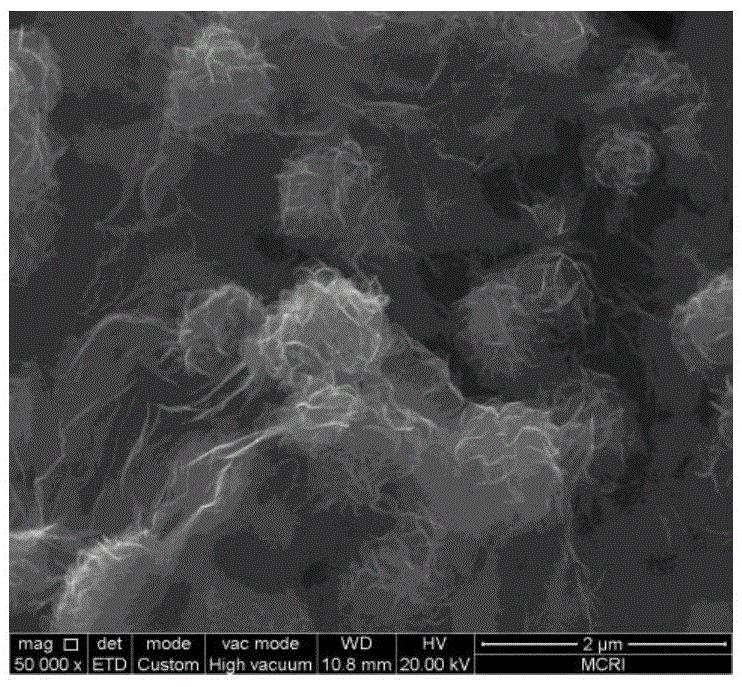

[0041] MoS prepared in this example 2 Petal-like MoS in rGO composites 2 The diameter of the cluster is 1.31 μm, and MoS is clearly visible on the surface of the cluster 2 Sheets, clusters are tightly combined with graphene sheets.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com