Permanent-magnet rapid operation mechanism

A fast-operating, permanent-magnet technology, applied in the direction of the power device inside the switch, can solve the problems such as the inability to obtain the rigid speed, limit the bistable permanent magnet operating mechanism, etc., achieve simple structure, convenient installation and debugging, and improve electrical life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention is further described as follows in conjunction with accompanying drawing and embodiment:

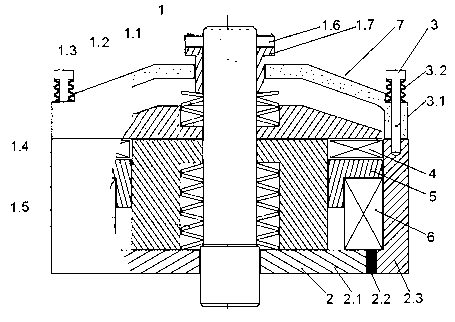

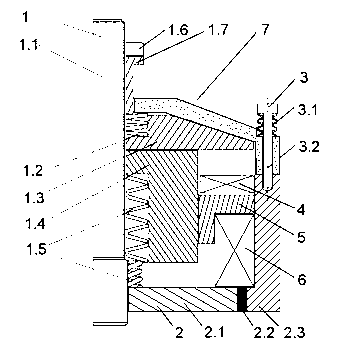

[0024] Such as figure 1 , 2 Shown: a permanent magnet quick operating mechanism, including a moving iron core assembly 1, a static iron core assembly 2, an opening coil 4, a flange 5, a closing coil 6, a cover plate 7 and a buffer assembly 3; The iron core assembly 1 is composed of a guide rod 1.1 and several components sleeved on the guide rod 1.1. The components are: moving iron core spring 1.5, moving iron core 1.4, repulsion disk 1.3, repulsion disk spring 1.2, adjustment nut 1.7 and lock nut 1.6; the static iron core assembly 2 includes a bottom plate 2.1 that is sleeved on the guide rod 1.1 and is in contact with the moving iron core spring 1.5, the bottom plate 2.1 is covered with a permanent magnet 2.2, and the permanent magnet 2.2 is covered There is a sleeve 2.3; there is a flange 5 in the cavity between the inner peripheral surface of the sleeve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com