Preparing method of AgSnO electric contact materials with uniform tissues

An electrical contact material, silver tin oxide technology, applied in metal material coating process, circuits, relays, etc., can solve problems such as aggregation and silver aggregation, and achieve the effect of simple process flow, easy production, and improved material transfer resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

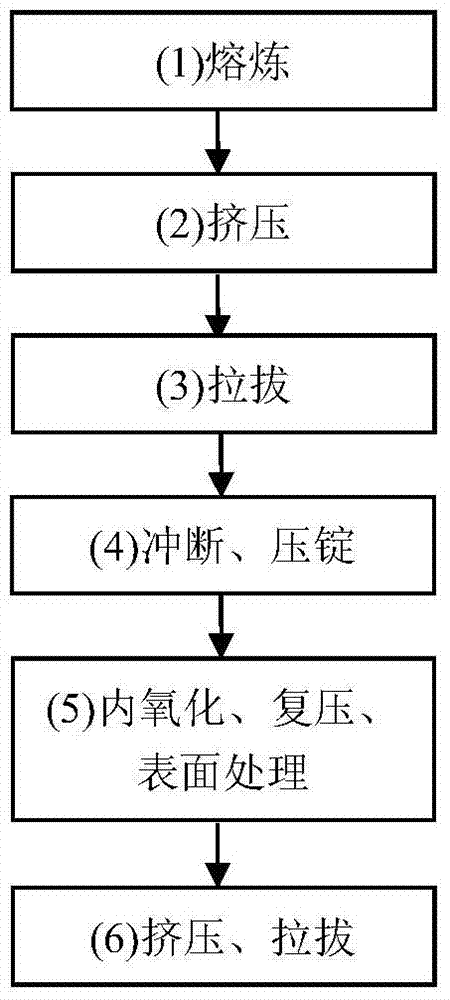

Method used

Image

Examples

Embodiment 1

[0037] (1) Melt Ag ingots, Sn ingots, and additives (In, Ga, Ce) with a composition ratio of Ag86Sn8In3Cu2Ga1 (by weight percentage) and cast them into round ingots, and then use a lathe to remove 4mm of surface oxide scale;

[0038] (2) extrusion, heating temperature 660°C, heat preservation 6h, obtain Φ4mm wire;

[0039] (3) Pulled to Φ2.5mm;

[0040] (4) punching and pressing the ingot, wherein the length of the broken wire is 30mm, the diameter of the spindle is 80mm, and the pressure is 8MPa;

[0041] (5) The oxidation temperature is 750°C, the oxygen pressure is 5MPa, the oxidation time is 5h, the diameter of the spindle after repressing is 85mm, the repressing pressure is 50MPa, and the surface of the spindle is turned to 4mm;

[0042] (6) The extrusion heating temperature is 900°C, and the holding time is 5 hours to obtain a Φ7mm wire, and then hot-drawn to a finished wire of Φ1.5mm;

[0043] (7) Make rivets with the wires of the above specifications, and conduct ele...

Embodiment 2

[0050] (1) Melt Ag ingots, Sn ingots, and additives (In, Zr, Co) with a composition ratio of Ag92Sn5In2Ce0.3Zr0.3Co0.2 (by weight percentage) and cast them into round ingots, and then use a lathe to remove surface oxidation Leather 3mm;

[0051] (2) extrusion, heating temperature 770°C, heat preservation 3h, obtain Φ3mm wire;

[0052] (3) Pulled to Φ2.5mm;

[0053] (4) punching and pressing the ingot, wherein the length of the broken wire is 20mm, the diameter of the spindle is 85mm, and the pressure is 12MPa;

[0054] (5) The oxidation temperature is 850°C, the oxygen pressure is 2MPa, the oxidation time is 10h, the diameter of the spindle after repressing is 85mm, the repressing pressure is 60MPa, and then the surface of the spindle is turned to 2mm;

[0055] (6) Extrusion heating temperature is 800°C, heat preservation for 8 hours, and then heat preservation time at 900°C for 2 hours, the wire specification after extrusion is Φ5mm, and then hot drawn to the finished wire ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com