Method for preparing Ag/La1-xSrxCoO3 electric contact composite material

A composite material, electrical contact technology, applied in contacts, circuits, electrical switches, etc., to improve wettability, save silver, and prolong service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

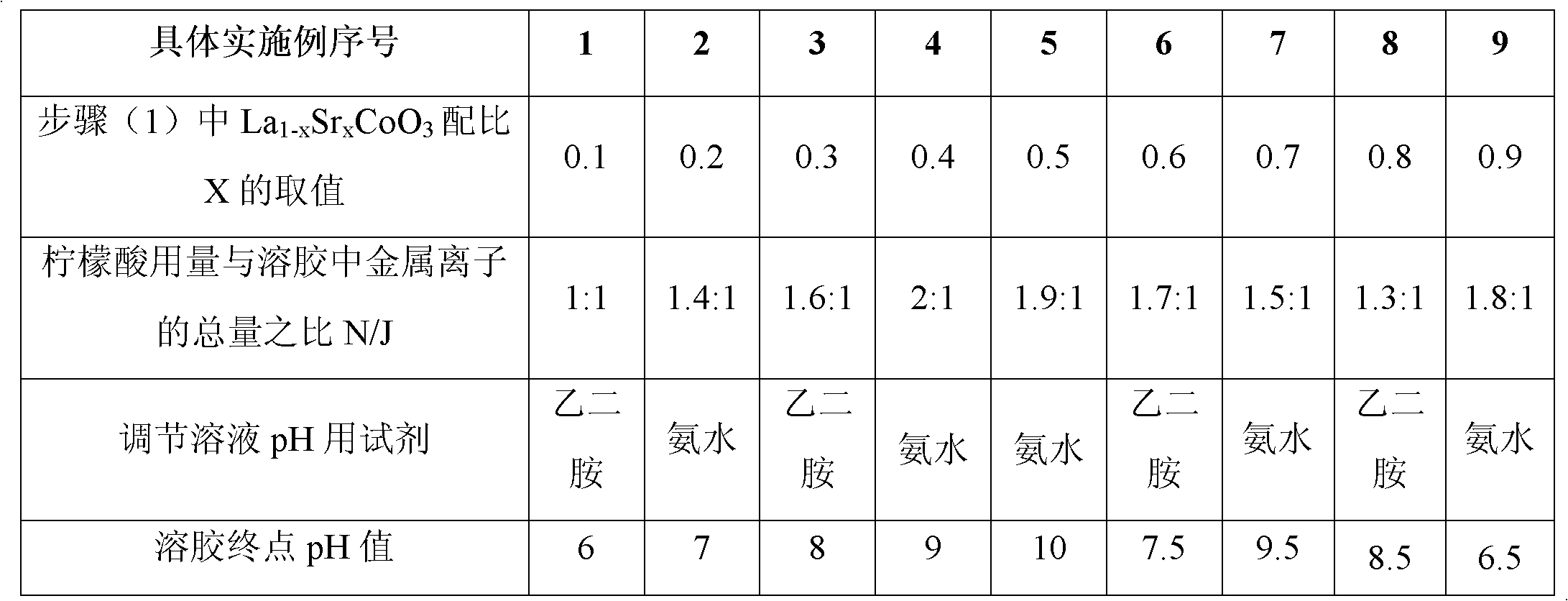

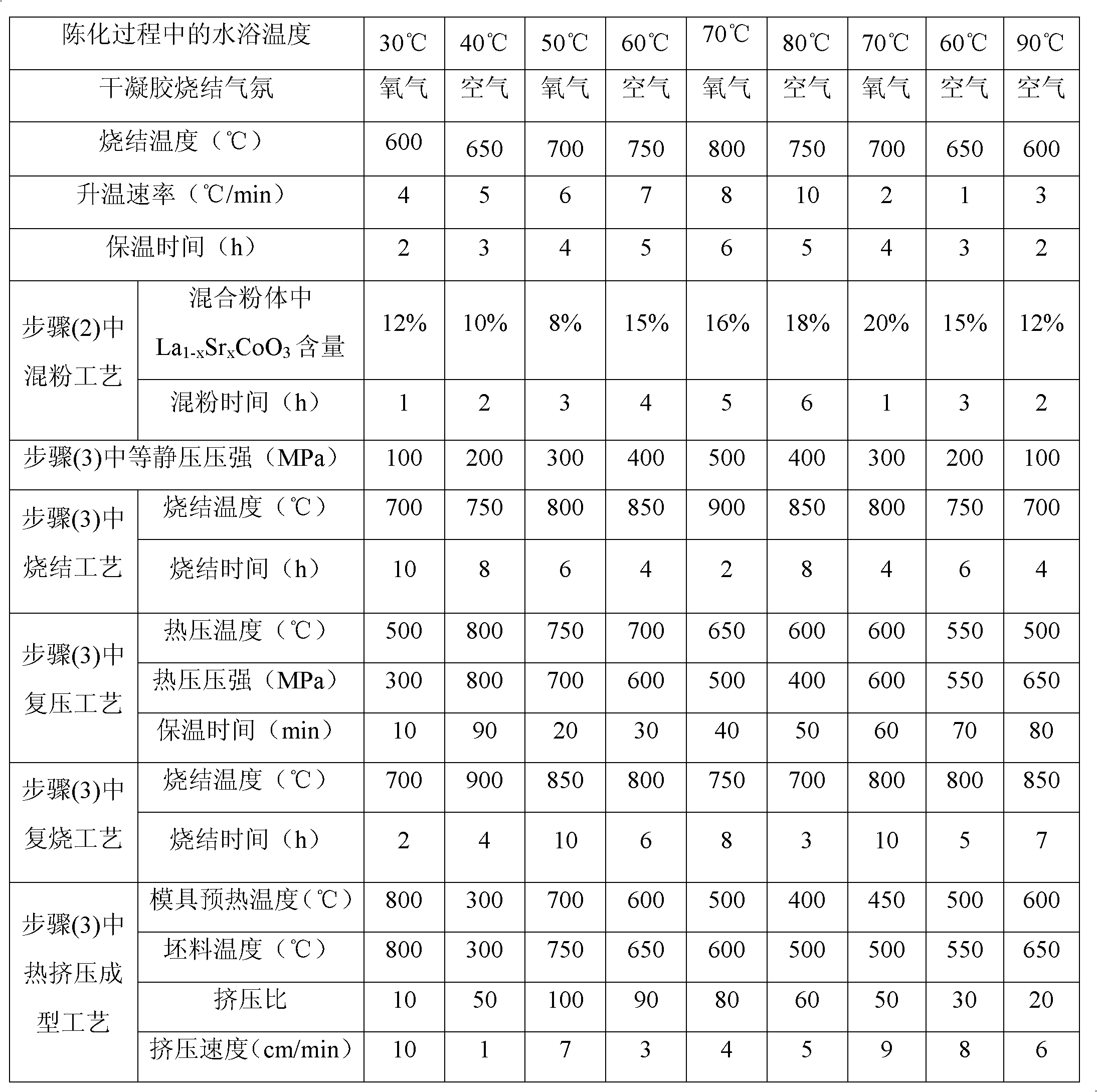

[0024] The present invention is further described by examples below.

[0025] The preparation method of the Ag / La1-xSrxCoO3 electrical contact composite material provided by the present invention specifically comprises the following steps:

[0026] (1) Prepare La by sol-gel method 1-x Sr x CoO 3 System conductive ceramic micro-nano powder;

[0027] (2) the above La 1-x Sr x CoO 3 Micro-nano powder and silver powder are mixed evenly in the V-shaped powder mixer, La 1-x Sr x CoO 3 The powder accounts for 8% to 20% of the total mass of the mixed powder;

[0028] (3) The uniformly mixed powder is pressed into a green body by isostatic pressing, then sintered, repressed, and refired in sequence, and finally hot-extruded to obtain Ag / La 1-x Sr x CoO 3 Electrical contact composites.

[0029] The sol-gel method adopted in step (1) prepares La 1-x Sr x CoO 3 The method of conducting conductive ceramic micro-nano powder in the system is: La(NO 3 ) 3, Sr(NO 3 ) 2 , Co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com