A command type safety valve testing system and method

A test system and safety valve technology, which is applied in the testing of mechanical parts, machine/structural parts testing, measuring devices, etc., can solve the requirement of reducing the inflation pressure of the storage tank, and cannot use the pressurized test method to command the opening and closing of the safety valve Functional testing and other issues to achieve the effect of improving test accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

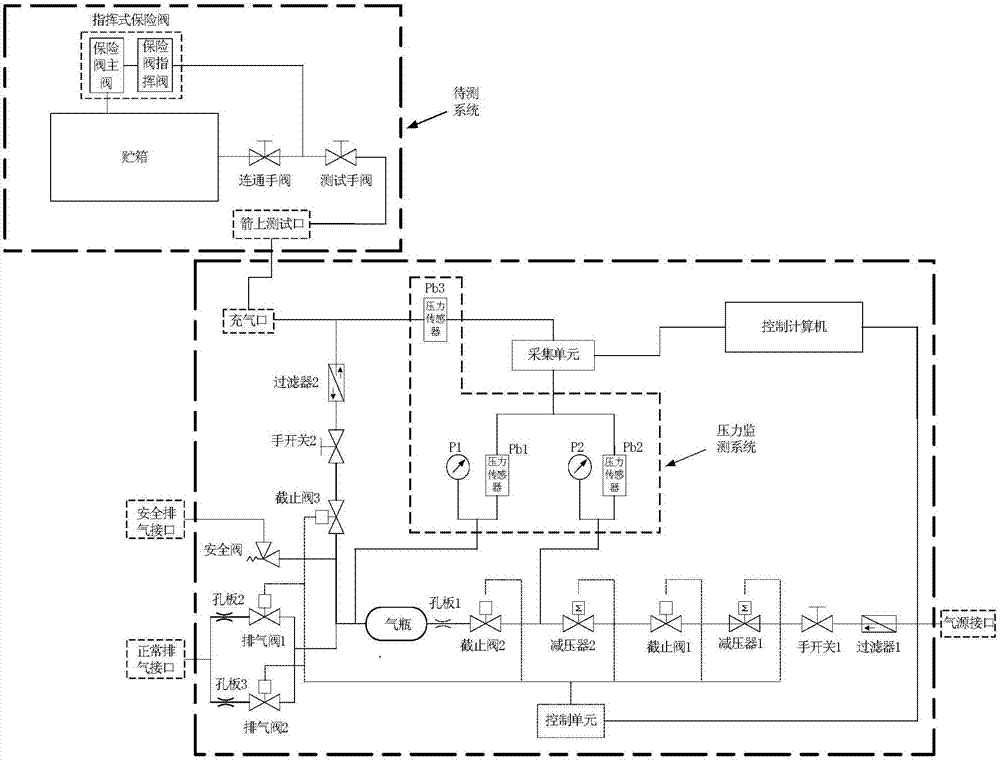

[0030] The basic ideas of the present invention are: the present invention relates to a command safety valve testing system and method, including: a control computer, a control unit, a collection unit, a supply and exhaust system, and a pressure monitoring unit. The supply and exhaust system can filter the source gas, decompress it to the target pressure value according to the demand, and then send it to the safety valve command valve, and realize the deflation function during and after the test; the control computer is used for the test system Terminal control, data display; the acquisition unit is used to collect the pressure data of each key point in the test system and transmit it to the control computer; the control unit is used to transmit the actions and decompression commands output by the control computer to the controlled pressure reducer, Stop valve, exhaust valve, etc., to realize gas decompression, gas circuit on-off control, and exhaust control. This system can a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com