Electromagnetic relay resistant to electric repulsive force

A technology of electromagnetic relay and electric repulsion, which is applied in the direction of electromagnetic relay, electromagnetic relay details, relays, etc., can solve the problems of electric repulsion damage, easy bounce of contacts, strong arc generation, etc., and achieve the balance of suction and reaction force and electrical contact Reliable, the effect of resisting short-circuit current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

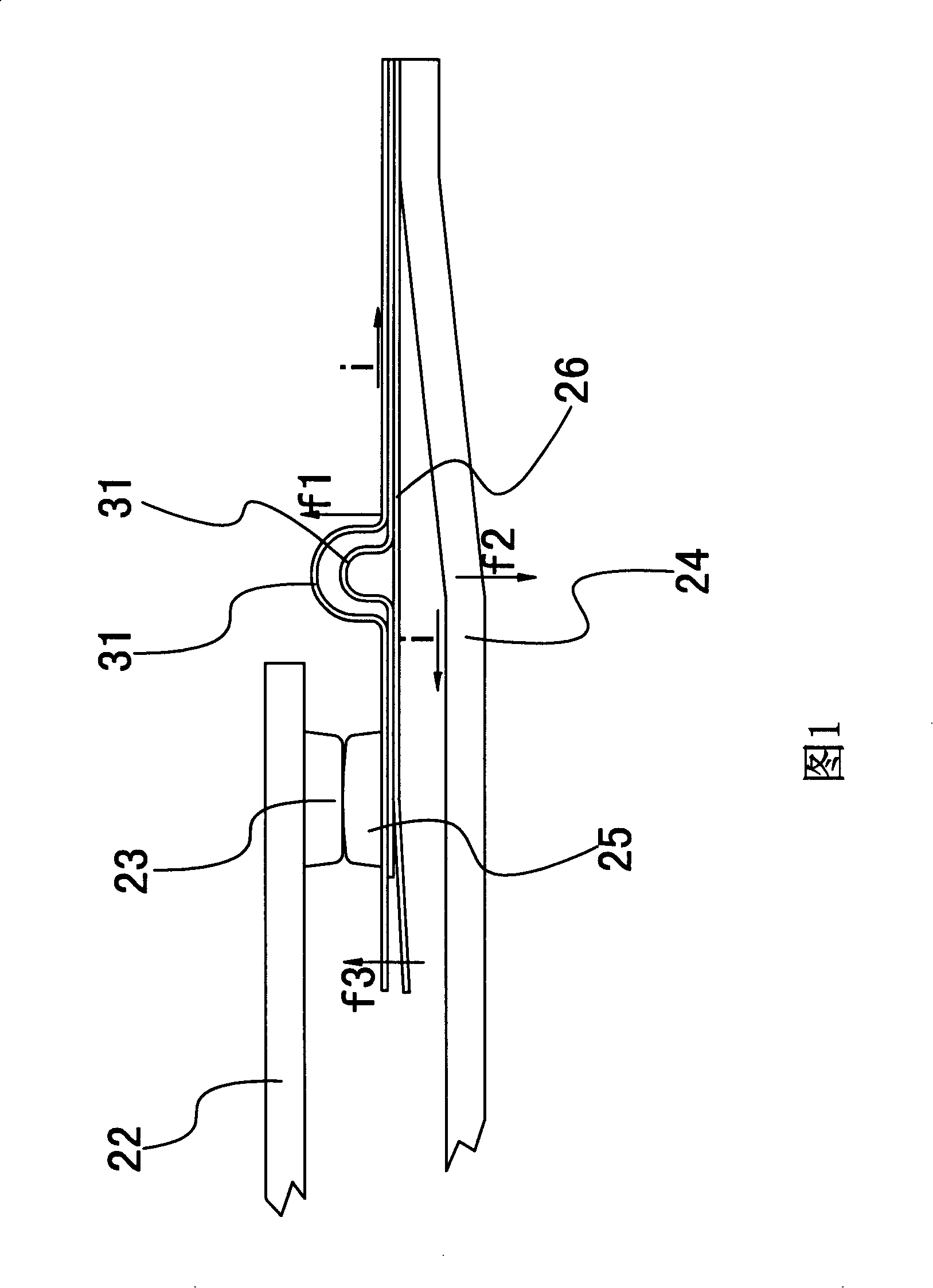

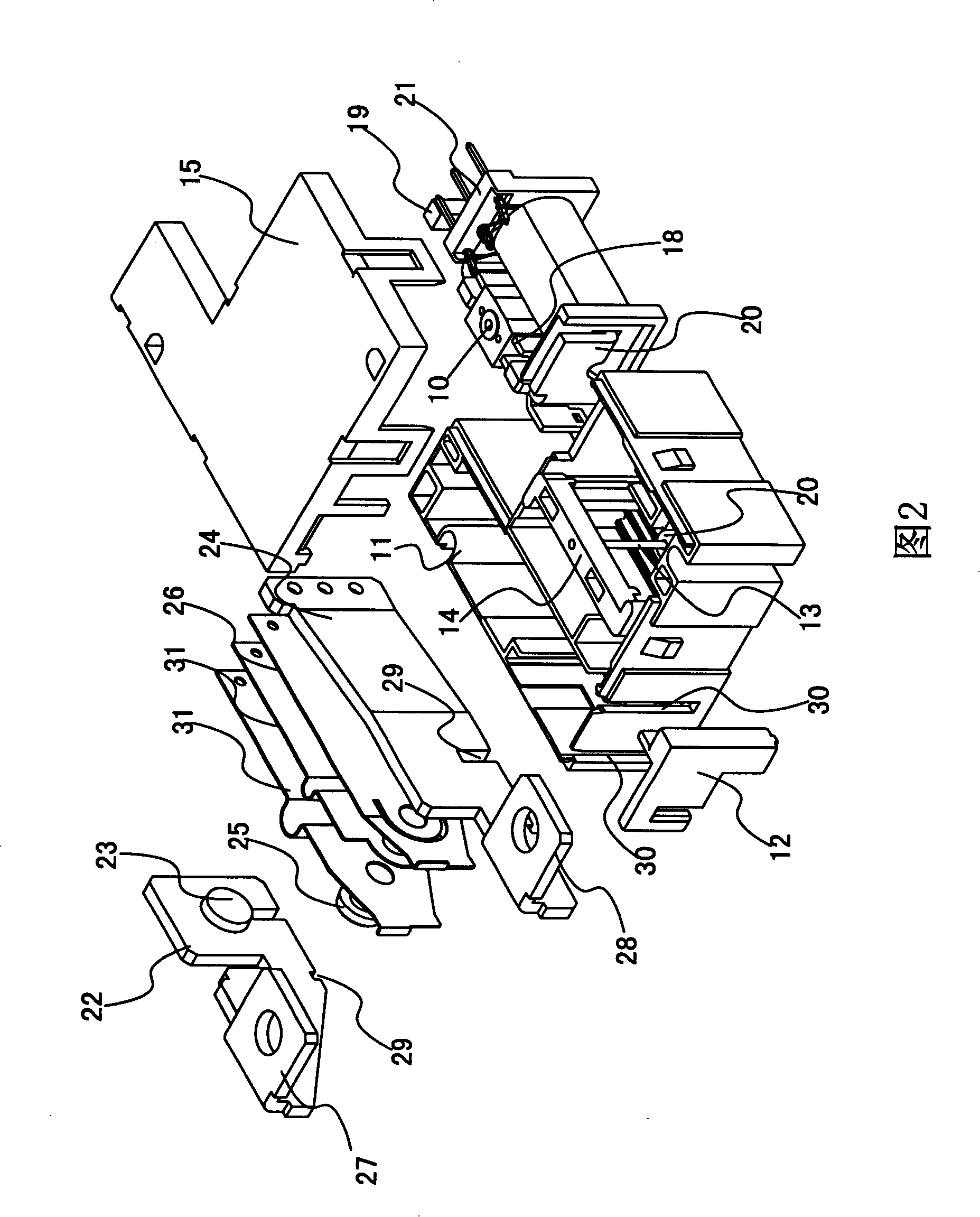

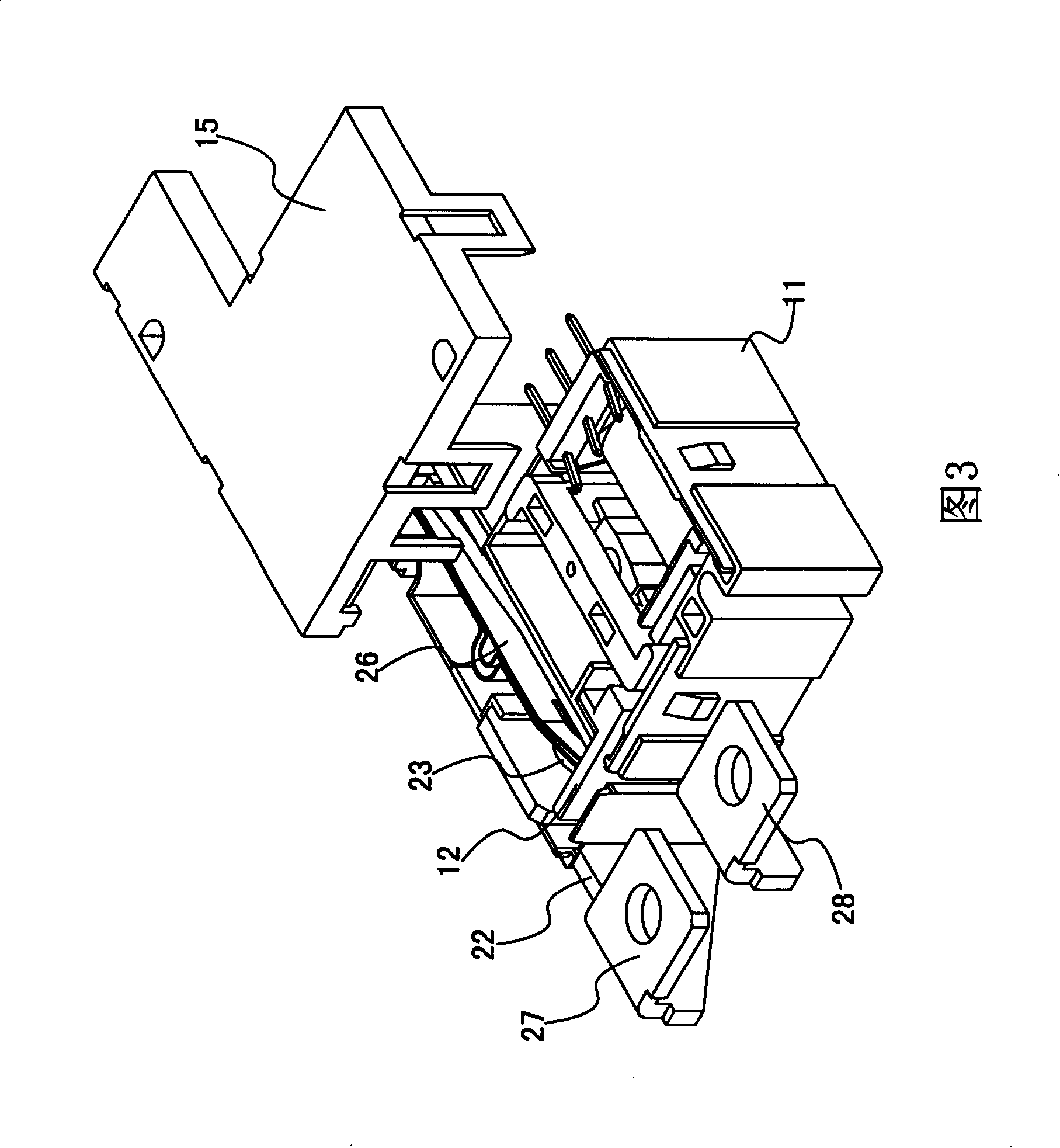

[0026] Please refer to FIG. 2 , an electromagnetic relay resisting electrodynamic repulsion, which has a contact system, an electromagnetic system 10 , a base 11 , a push card 12 , a shaft 13 , a fixing frame 14 and a housing 15 .

[0027] Please refer to Figure 2, Figure 3, Figure 5 as well as Image 6 , the above-mentioned base 11 is provided with a reverse buckle 16, and the above-mentioned shell 15 is provided with a reverse buckle 17, and the shell 15 and the base 11 are assembled together through the phase-tight buckle between the reverse buckle 16 and the reverse buckle 17 . In this embodiment, the assembling method adopts the reverse interlocking method, but it is not limited thereto, and other assembling methods should also fall within the protection scope of the present invention.

[0028] Please refer to Fig. 2, the fixed frame 14 is installed in the base 11; the electromagnetic system 10 includes an armature 18, a permanent magnet 19, a yoke 20 and a coil frame ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com