High-performance multineedle electrostatic spinning jet device

An electrospinning and spinning device technology, applied in the field of multi-needle electrospinning spinning devices, can solve the problems of not reaching the spinning efficiency, uneven distribution of field strength at the spinneret, and unable to spray all normally. Efficient and adaptable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] specific implementation plan

[0012] The top views of the following embodiments further illustrate the present invention.

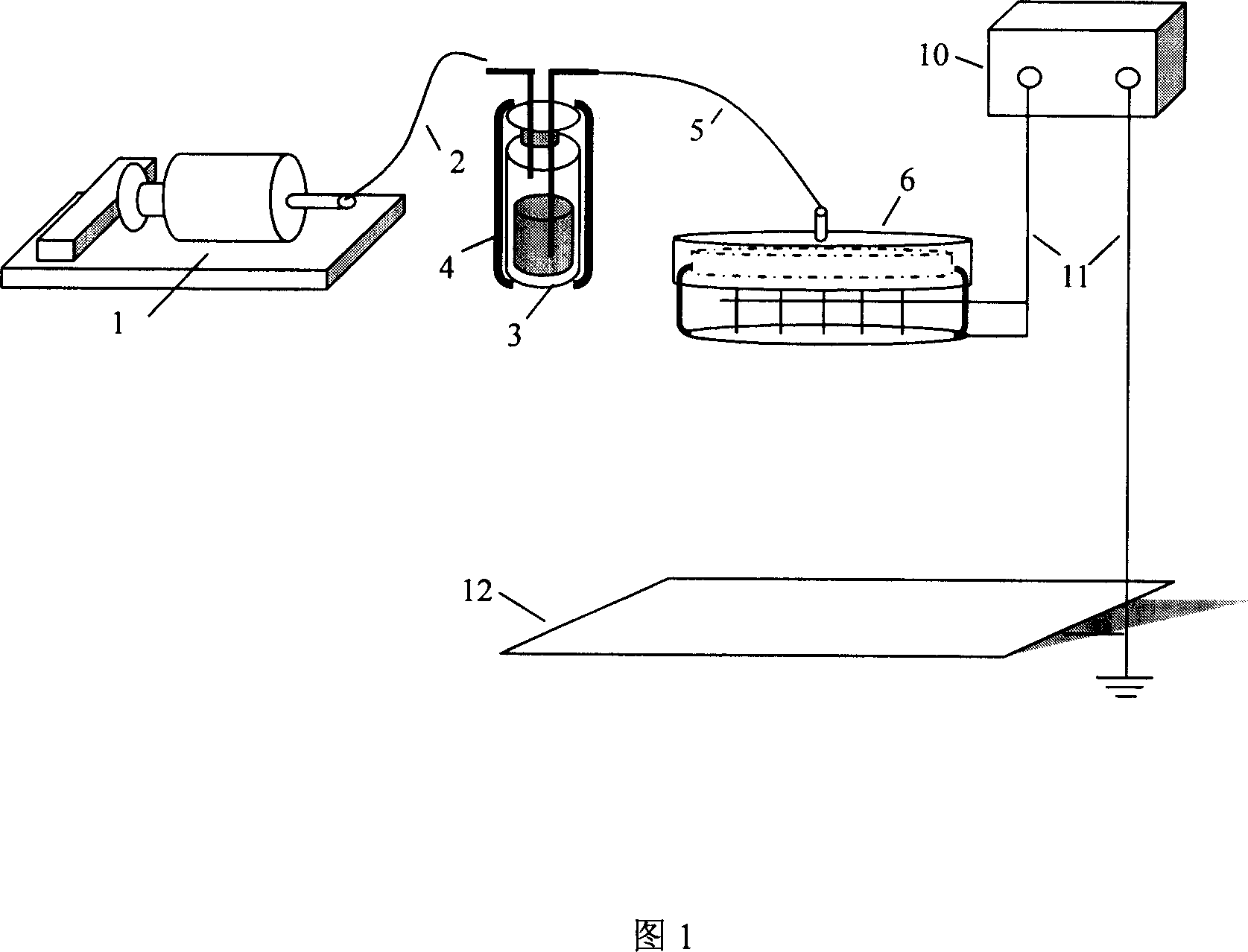

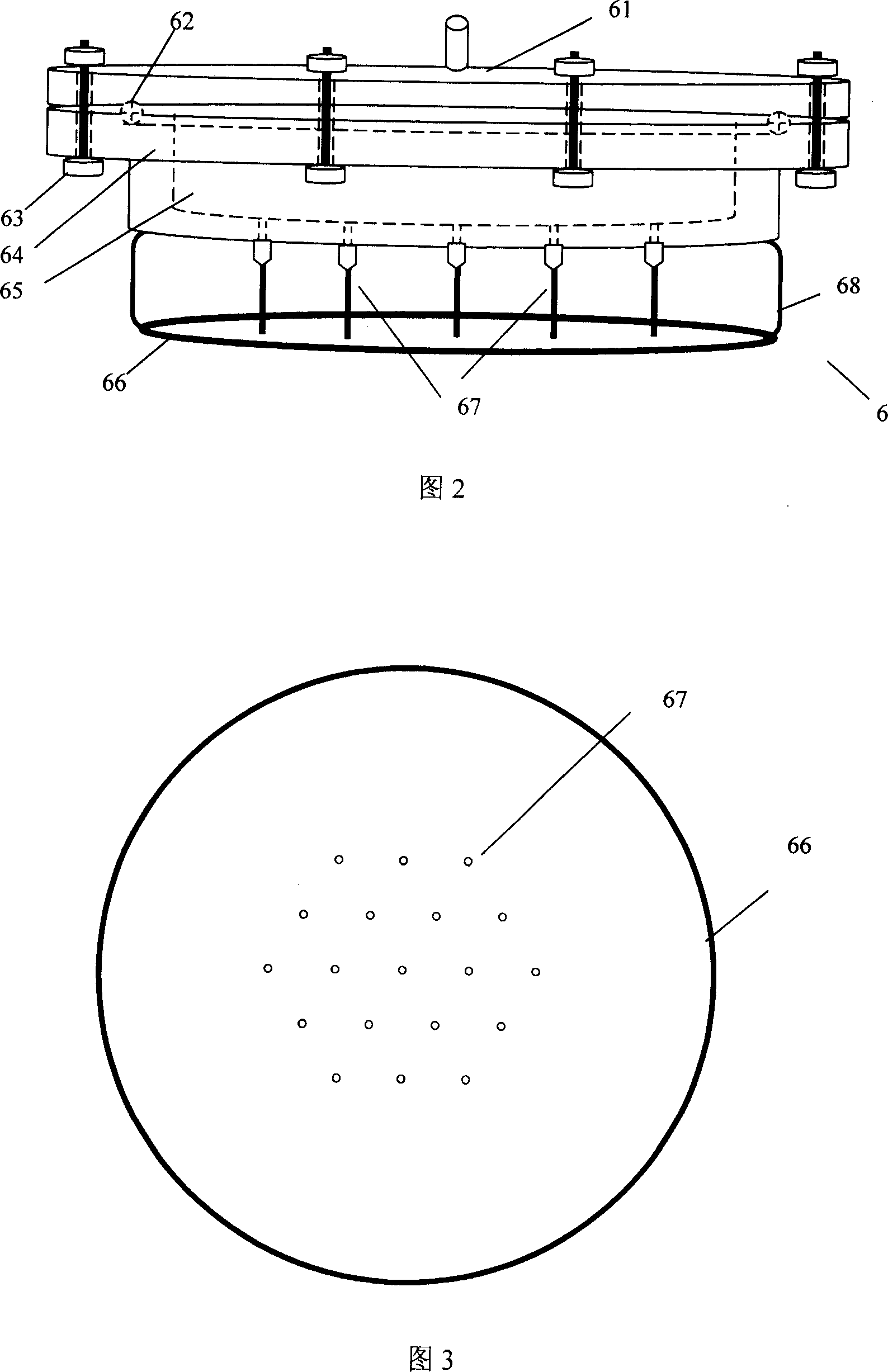

[0013] Referring to Figures 1-3, the high-efficiency multi-needle electrospinning spinning device of the present invention includes: a constant pressure liquid supply system, which includes an air pump 1 and a liquid storage tank 3 connected to the outlet of the air pump 1; connected to the constant pressure liquid supply system The spinneret 6 at the outlet end, the receiving electrode plate 12 and the electrostatic generator 10 arranged under the spinneret 6 . The constant-pressure liquid supply system for spinning liquid ensures uniform and continuous jet flow. The constant pressure liquid supply system can adopt a system composed of a traditional nitrogen cylinder, a pressure reducing valve and a steady flow valve, and the pressure regulator valve and a rotameter are used in combination; a hydraulic liquid supply system or a mechanical liquid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com