Electromagnetic repulsion force system and permanent magnetic system coupled self-adapting control mechanism

A technology of electromagnetic repulsion and permanent magnet mechanism, applied in circuits, electrical switches, electrical components, etc., can solve problems such as unfavorable rapid operation of operating mechanisms, unfavorable service life of circuit breakers, and increased mass of eddy current discs, and reduce mechanical strength. requirements, reducing mass, avoiding the effect of high-speed motion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

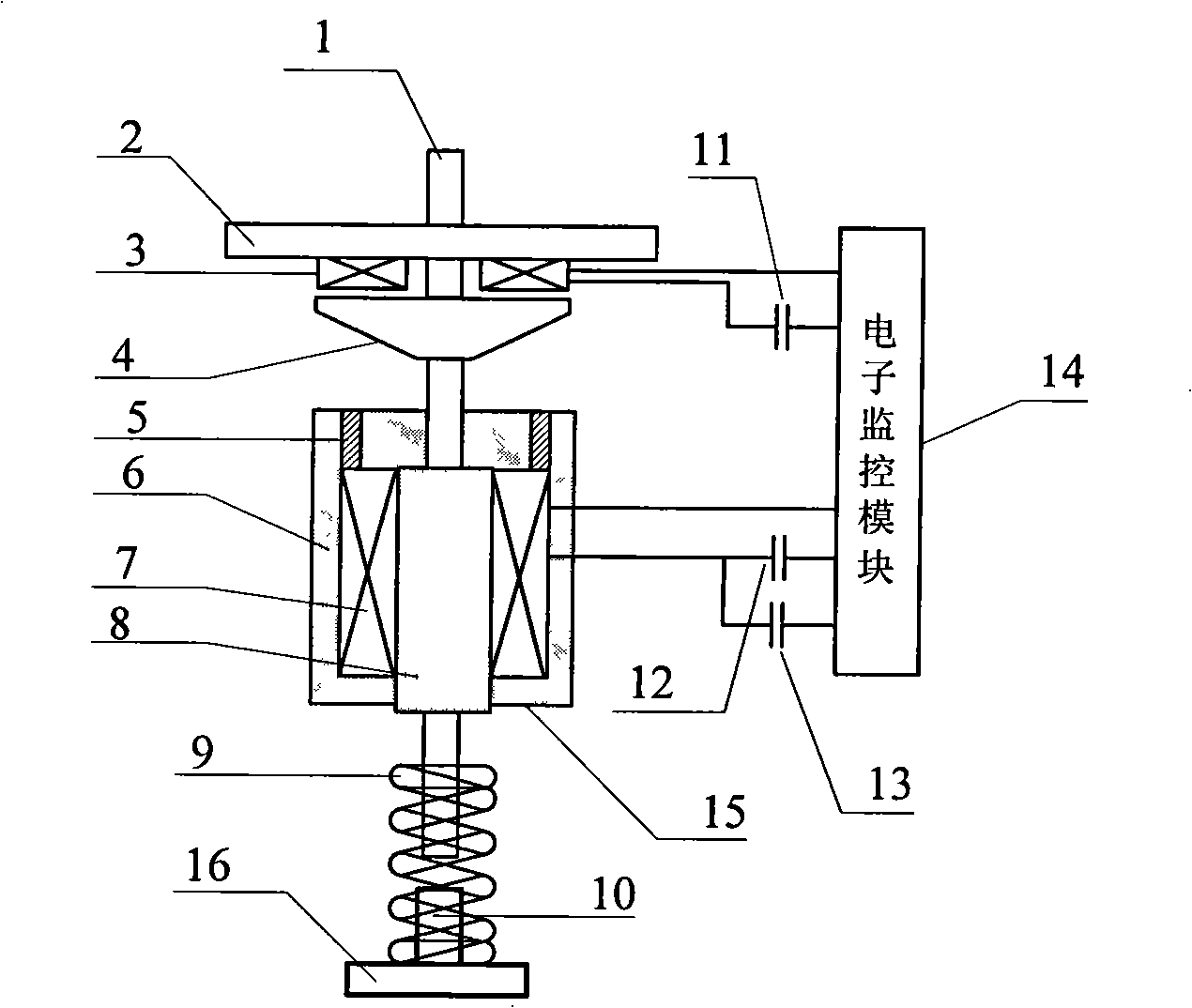

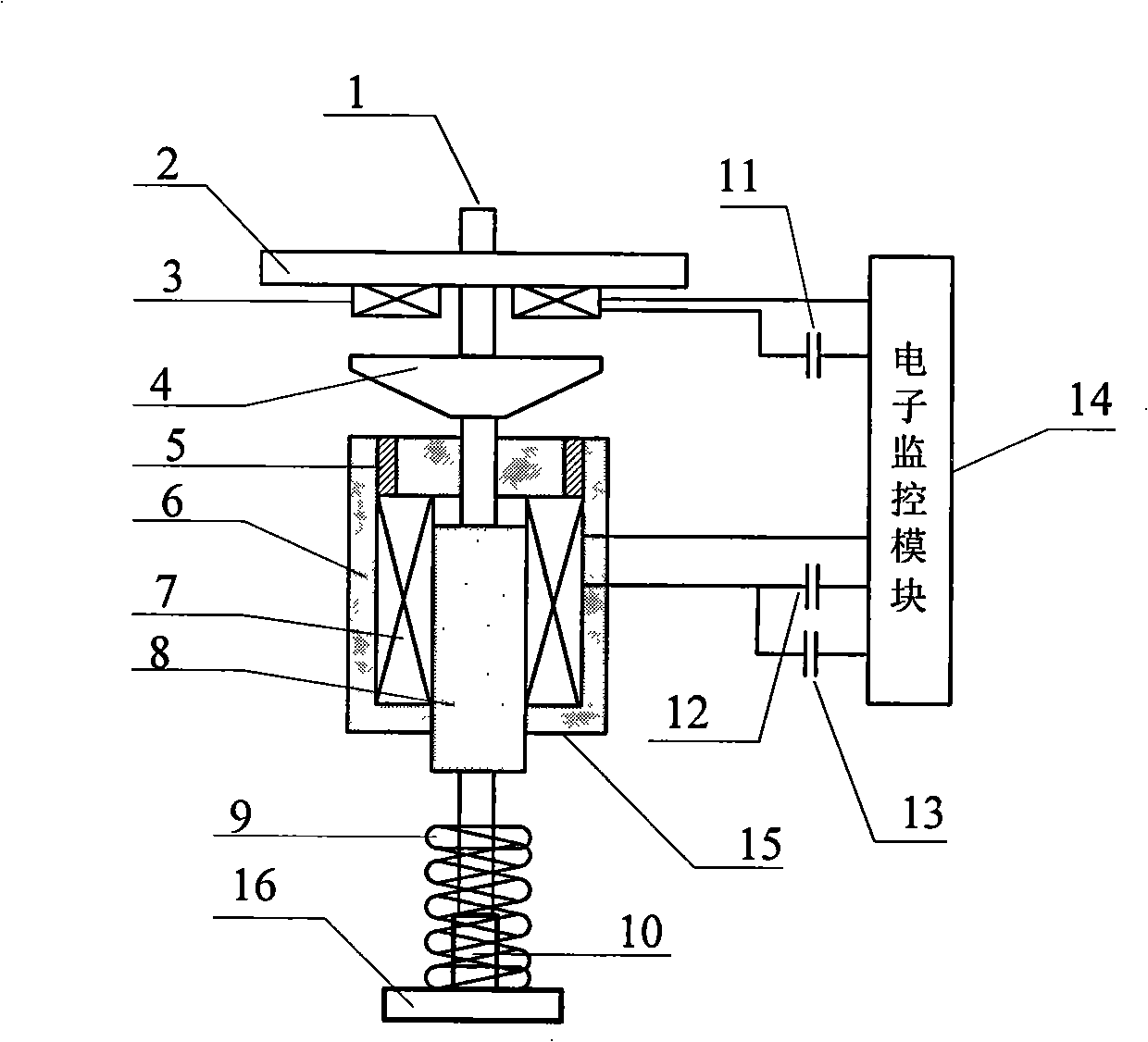

[0019] see figure 1 , figure 2 As shown, the present invention is mainly composed of an electromagnetic repulsion device and a monostable permanent magnet mechanism connected through an axially movable drive rod.

[0020] The electromagnetic repulsion device has the electromagnetic repulsion device metal eddy current disc 4 and the electromagnetic repulsion device coil mounting plate 2 fixedly arranged on the driving rod 1, and the electromagnetic repulsion device coil mounting plate 2 can be fixed on the applied coil of the present invention. On the breaker frame, the electronic monitoring module 14 controls the coil power supply capacitor 11 of the electromagnetic repulsion device to supply power to the coil 3 of the electromagnetic repulsion device.

[0021] The monostable permanent magnet mechanism has the monostable permanent magnet mechanism moving iron core 8 fixedly arranged on the drive rod, the monostable permanent magnet mechanism static iron core 6 fixed on the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com