Aluminum blade of fan and manufacturing technology thereof

A technology of aluminum alloy and blades, which is applied in the direction of mechanical equipment, engine components, machines/engines, etc., can solve the problems of limiting fan speed, flow rate, flow rate, low product qualification rate, blade breakage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

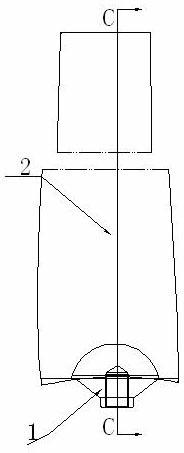

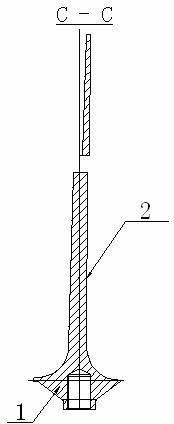

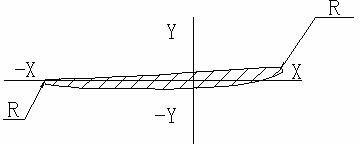

[0049] See Figure 1 ( Picture 1-1 , Figure 1-2 , Figure 1-3 ), the 30-inch aluminum alloy blade consists of two parts: the Picture 1-1 Middle: No. 1 is the threaded shank part of the blade installation, and No. 2 is the blade body of the blade. The product requires the installation of threaded handles and threaded holes to be machined to ensure dimensional accuracy. The blade body basin arc and back arc are non-machined surfaces. The surface roughness of the blade body 2 reaches 3.2 μm. 0.5mm, the light transmittance between the airfoil template and the airfoil surface is required to be ≤1.5mm, and the back arc of the air inlet and exhaust edge of the airfoil 2 and the basin arc are required to be connected by R. According to the above technical requirements, the blade should belong to precision forging grade.

[0050] See Figure 2 ( diagram 2-1 , Figure 2-2 , Figure 2-3 , Figure 2-4 , Figure 2-5 ), the 30-inch aluminum alloy blade forging drawing, in order to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com