Motor parallel transmission portable angle grinder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

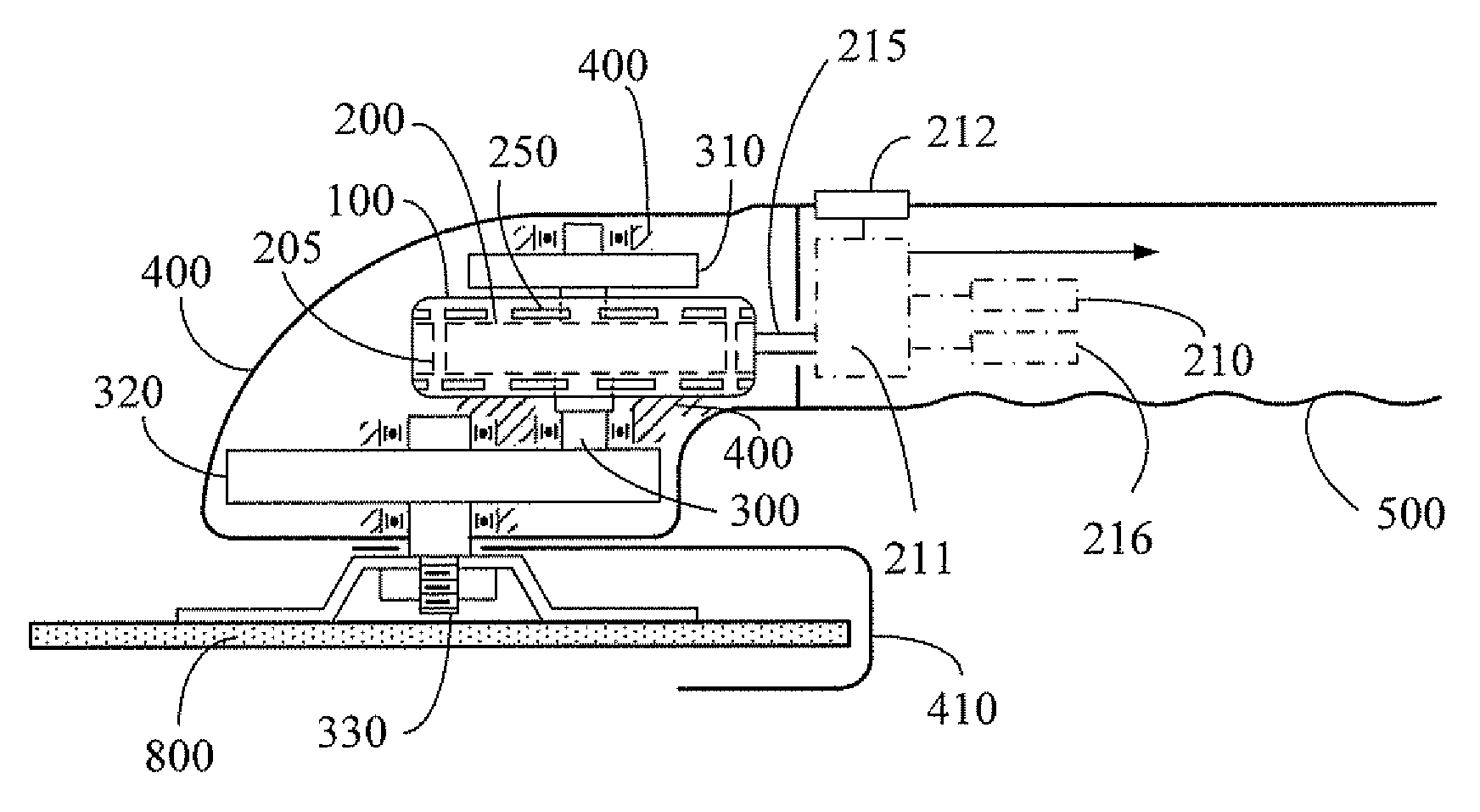

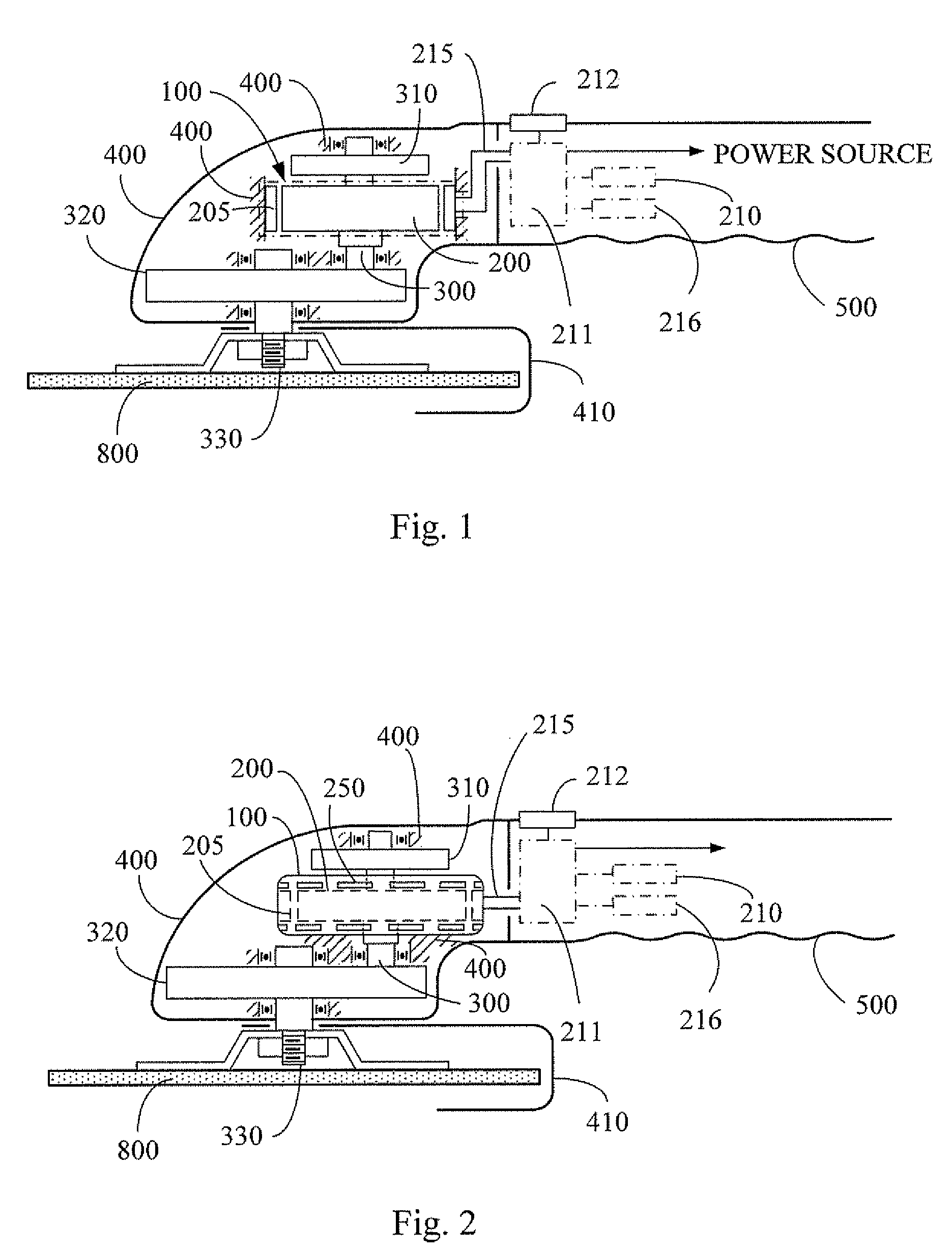

[0028]The present invention relates to a motor parallel transmission portable angle grinder with a motor rotating part spindle parallel installed in a position adjacent to a grinding wheel spindle to form a parallel transmission device driving the grinding wheel. By means of the parallel transmission device, the present invention prevents the emission of noise made by angle type transmission devices; and / or an inertial body is installed on the motor rotating part to form a flywheel to improve the grinding, polishing and machining or cutting abilities of the grinding wheel; and / or a motor is established to be open or semi-hermetic for the space from the interior to a housing and / or a handle of the motor to improve the effect of heat dissipation outward. Aside from a manually controlled electromechanical device, a power storing and discharging device is also installed in the handle for use as a power source. FIG. 1 is a structural drawing showing the main components of the motor paral...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com