Pneumatic turning device and locker using the same

A flipping device and airtight technology, applied in the field of pneumatic flipping devices and lockers, can solve problems such as unsafe, complex motor structure, and easily damaged dampers, so as to solve safety problems, simple processing technology, and avoid pinching hands. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below, in conjunction with accompanying drawing and specific embodiment, the present invention is described further:

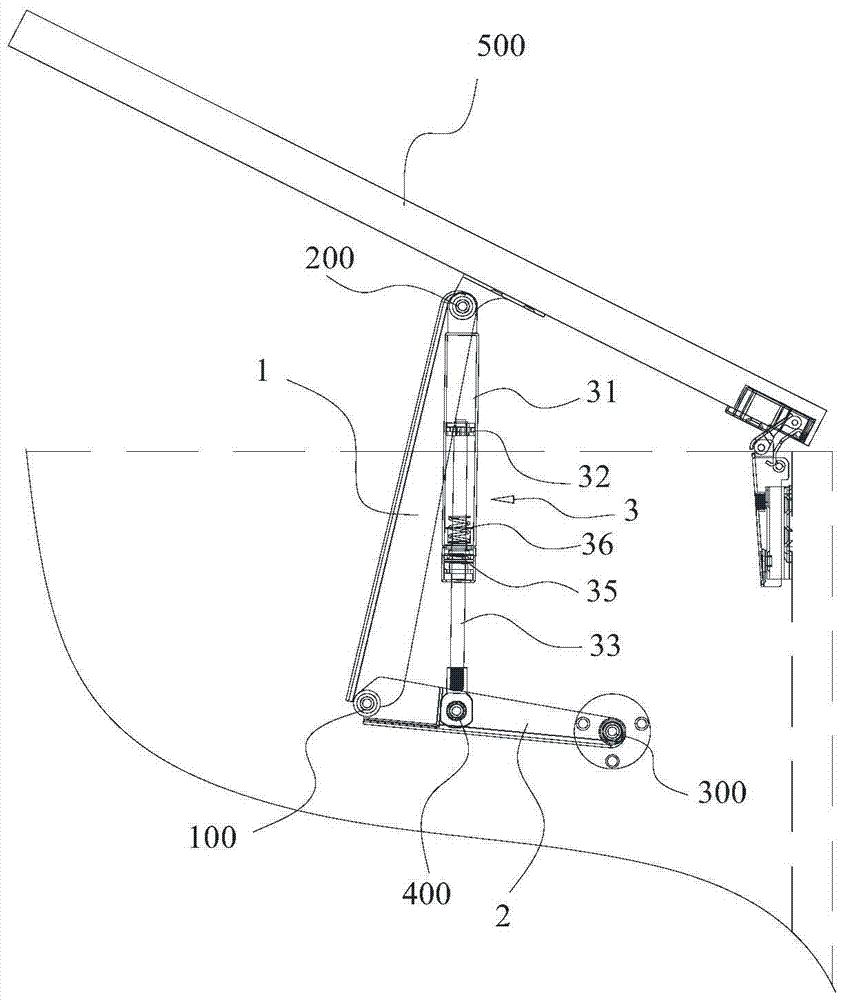

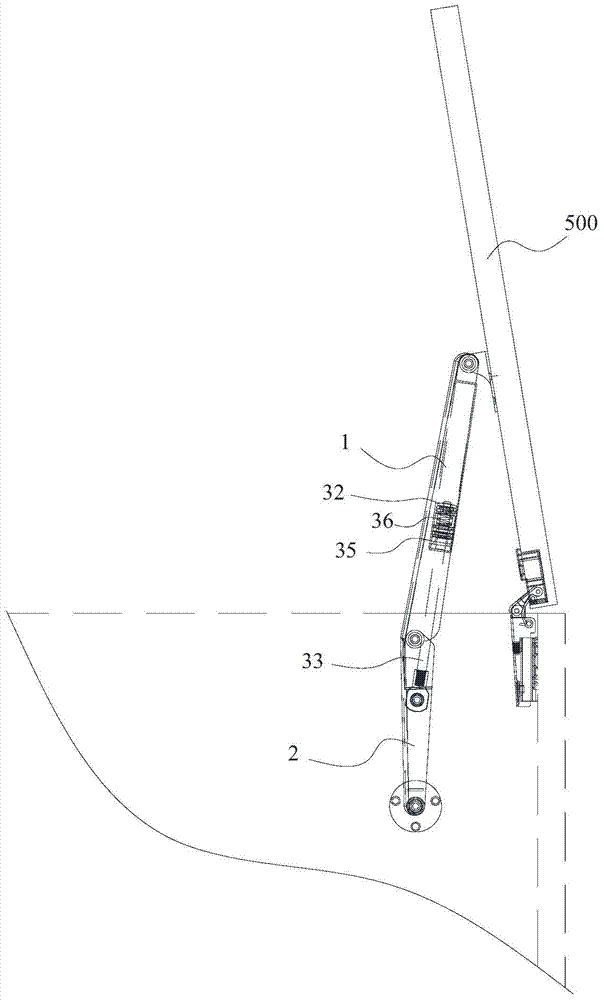

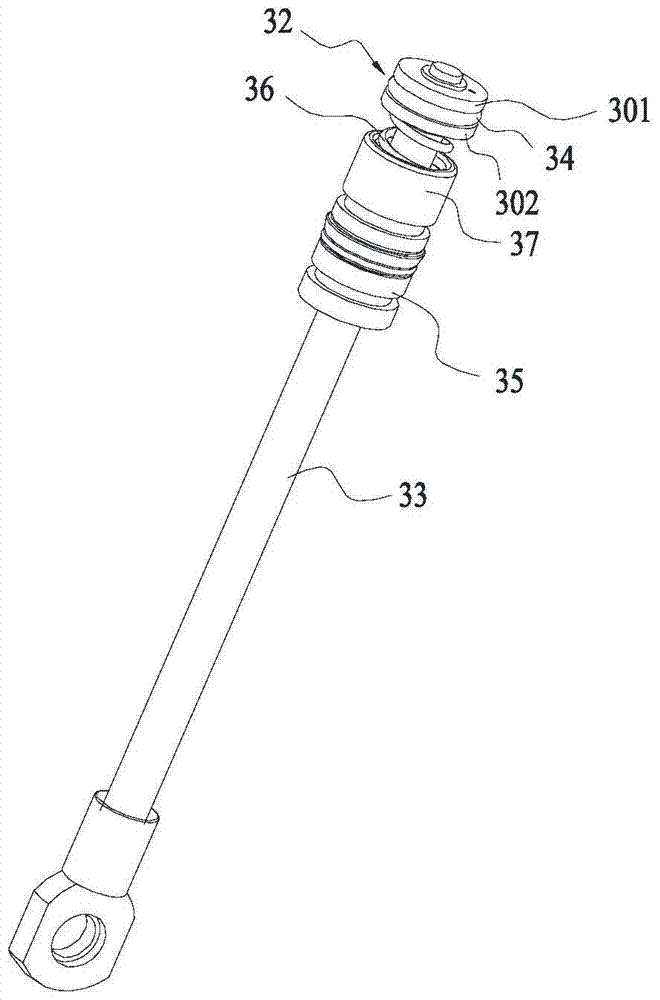

[0028] Such as Figure 1~4 The shown pneumatic turning device comprises a long arm 1, a short arm 2 and a cylinder 3, one end of the long arm 1 is hinged to one end of the short arm 2 to form a first hinge point 100, and the other end of the long arm 1 is set as the first hinge end 200, the other end of the short arm 2 is set as the second hinged end 300, and the cylinder 3 includes a cylinder liner 31, a piston 32, a piston rod 33, a sealing ring 34, a guide sleeve 35, a spring 36, lubricating oil (not shown in the figure) ) and nitrogen (not shown in the figure), the guide sleeve 35 is airtightly inserted into the sleeve port of the cylinder liner 31, the lubricating oil and nitrogen are built into the cylinder liner 31, and the end of the cylinder liner 31 opposite to the sleeve port is hinged to the first The end 200 is hinged, the piston rod 33 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com