Lifting type quenching mechanism for profile steel machining and production

A lift-type and elevator technology is applied in the field of lift-type quenching mechanisms for profile steel processing and production, which can solve the problems that cleaning and maintenance affect profile steel processing and production, steam cannot be recycled and reused, and high processing costs, so as to improve resource recovery and utilization, and facilitate later stages. Machining and handling, compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

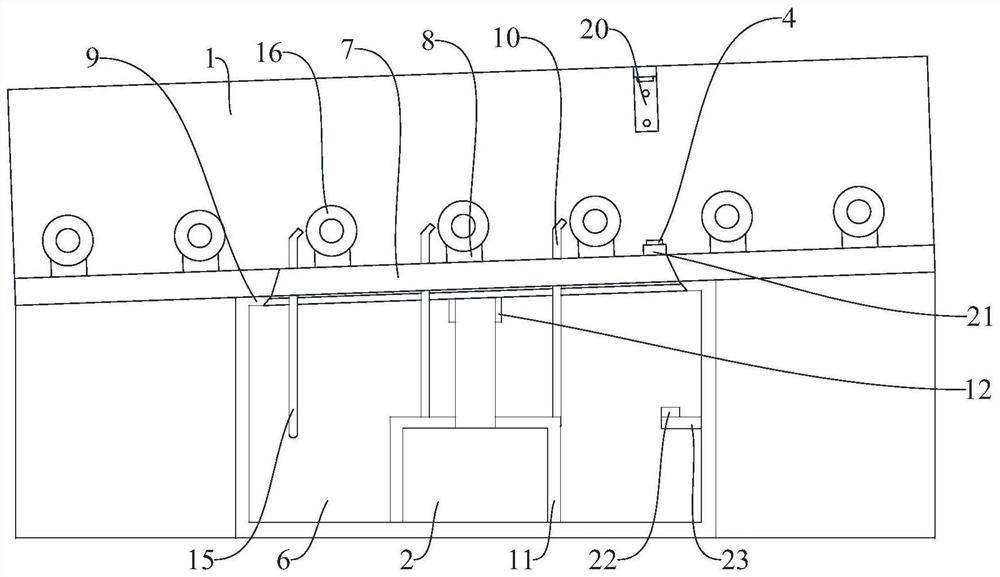

[0035] Embodiment: When the electric lift 2 drives the bottom lifting platform 7 to descend, the bottom of the bottom lifting platform 7 squeezes and presses the control switch 22 to control the electric lift 2 to rise and reset.

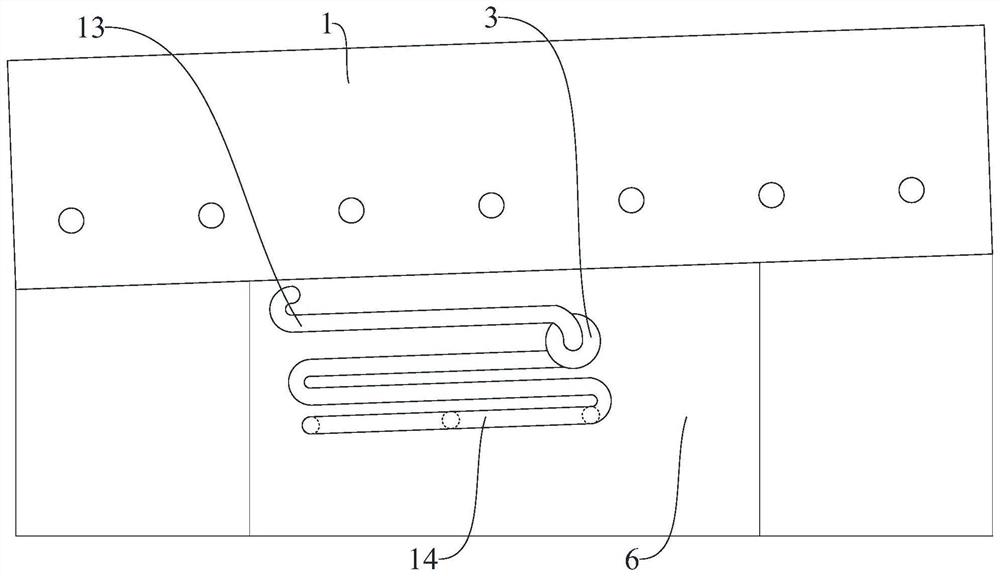

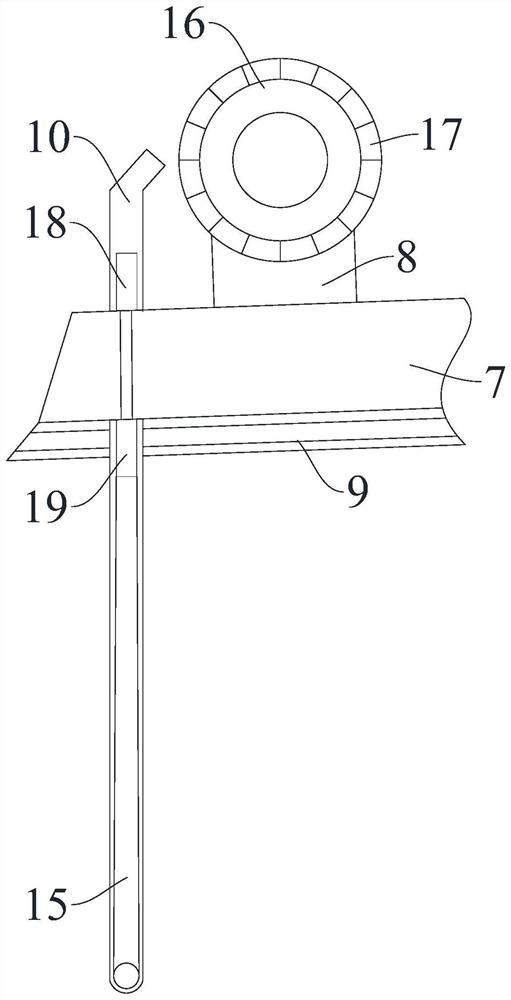

[0036]An elevating quenching mechanism for section steel processing and production according to the present invention provides a bottom elevating opening 5 on the lower surface of the main frame body 1, and a bottom quenching tank body with a built-in electric elevator 2 and a bottom elevating platform 7 is fixed with bolts below the bottom elevating opening 5 6. The steel on the bottom lifting platform 7 is driven by the electric elevator 2 into the bottom rubbing tank 6 for quenching treatment. By directly installing it on the existing conveyor belt, it makes the structure more compact and the transformation is more convenient. The transformation cost and The adaptation requirements are low, and it is convenient to popularize and popularize; on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com