Noise treatment method and system for paper mill

A technology for noise treatment and paper mills, which is applied to components of pumping devices for elastic fluids, non-variable pumps, pump components, etc., and can solve problems that affect the noise reduction and noise reduction effects of noise reduction equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

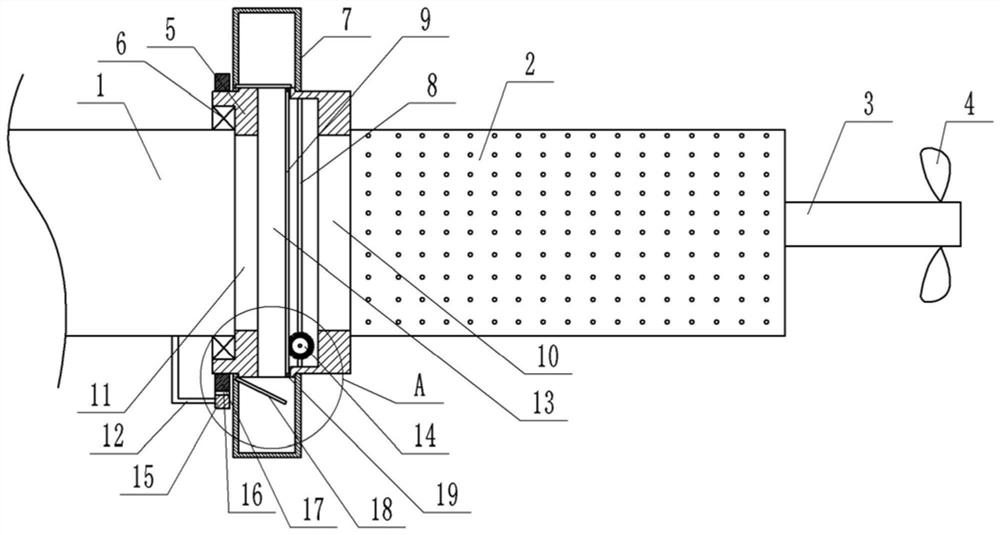

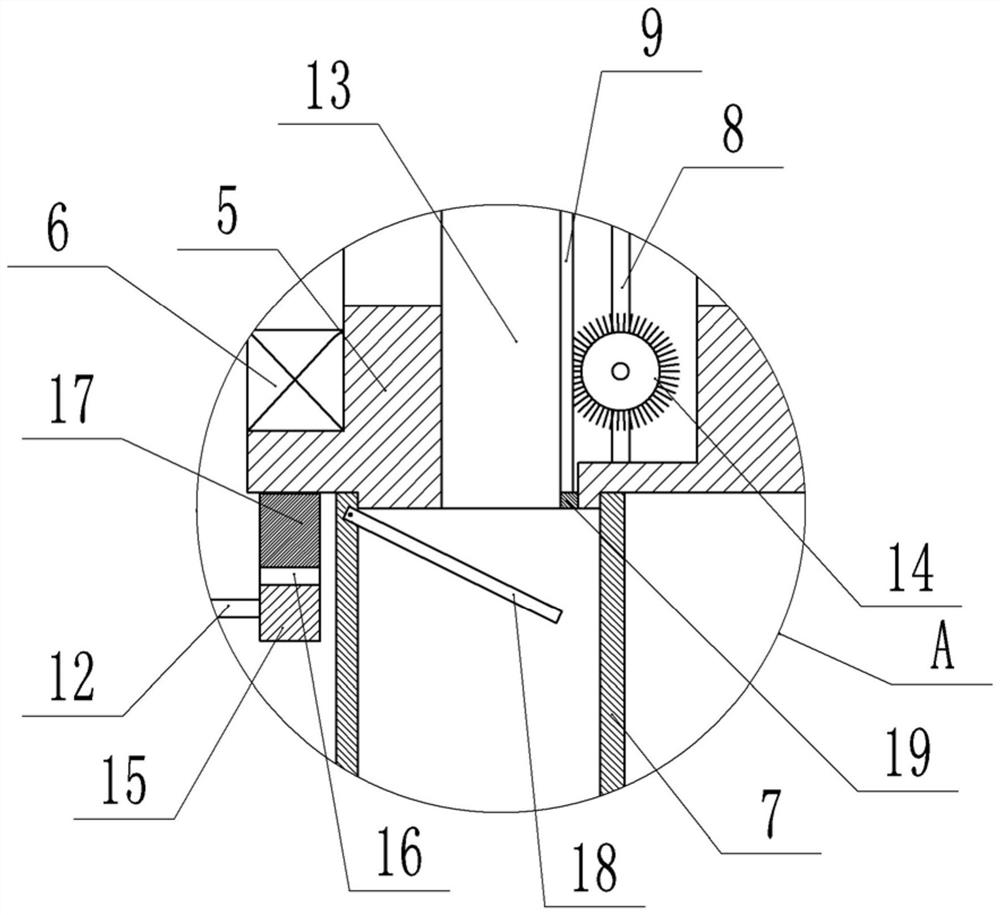

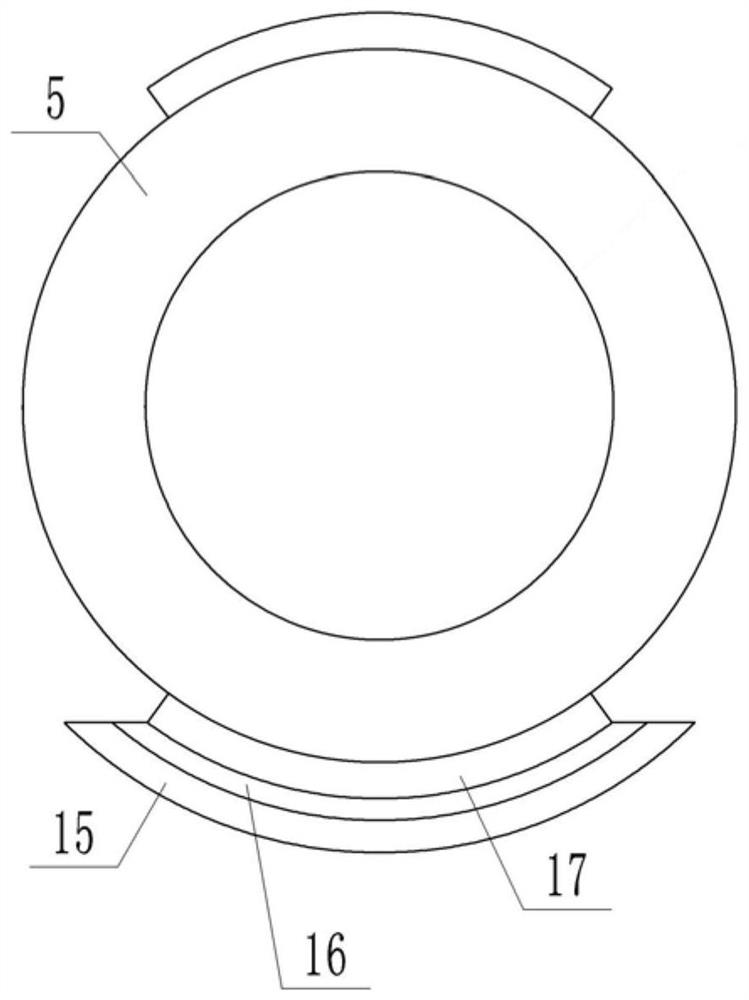

[0029] Basic as attached figure 1As shown: the noise treatment system used in paper mills, including the silencer pipe 2 and the rotating sleeve 5, the left end of the silencer pipe 2 is fixedly connected to the rotation sleeve 5, the specific fixing method is: the left end of the silencer pipe 2 is welded with a flange , bolts are connected between the flange plate and the rotating sleeve 5. The rotating sleeve 5 is provided with an air inlet 11 for communicating with the air outlet pipe 1 of the fan and an air outlet 10 for communicating with the silencer pipe 2. The air inlet 11 is located on the left side of the air outlet 10, and the rotating sleeve 5 rotates through the bearing 6 Connect to the outlet pipe 1 of the fan. The interior of the rotating sleeve 5 is provided with a dust filter chamber 13, the dust filter chamber 13 is located on both sides of the air inlet 11 and the air outlet 10, the dust filter chamber 13, the air inlet 11 and the air outlet 10 are connect...

Embodiment 2

[0040] combine Figure 4-Figure 5 As shown, the outer side of the rotating sleeve 5 is fixed with a plurality of telescopic rods 20 by screws, and the circumference of the plurality of telescopic rods 20 is evenly distributed on the rotating sleeve 5, and the end of the telescopic rods 20 away from the rotating sleeve 5 is fixedly connected with an iron ball 21 by screws. The telescopic rod 20 in this embodiment comprises two sleeves that are nested in each other. The inside of the telescopic rod 20 is provided with an extension spring, and the two ends of the extension spring are respectively welded on the iron ball 21 and the rotating sleeve 5. Under normal conditions, it is in a contracted state under the action of a tension spring. combine Figure 5 As shown, the outer side of the rotating sleeve 5 is provided with a magnet 24 for attracting the iron ball 21, the magnet 24 is fixed on the air outlet pipe 1 of the fan through the frame, and the magnet 24 is located on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com