Seepage-proofing processing method of channel concrete panel crack

A technology for a concrete panel and a treatment method, which is applied in water conservancy projects, marine engineering, construction, etc., can solve the problems that resin mortar is difficult to adapt to large deformation, difficult to apply uniform pressure, and high cost, and can improve the bonding, sealing, water-stopping effect and resistance to resistance. The effect of water flushing and peeling ability, improving adhesive strength and reducing peeling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] In this embodiment, the crack width is 1-3 mm.

[0024] 1. Material properties

[0025] The elastic anti-seepage material is selected as the HPU-2 sealant produced by Henan Sida Engineering Technology Co., Ltd. The main performance indicators: the tensile strength of the coating film is 4.0MPa, the elongation at break is 560%, and the bonding strength is 2.5MPa (the base surface is painted ZP-1 primer produced by Henan Sida Engineering Technology Co., Ltd.), the surface drying time is 2 hours, and the color is off-white (similar to the color of concrete).

[0026] 2. Construction technology

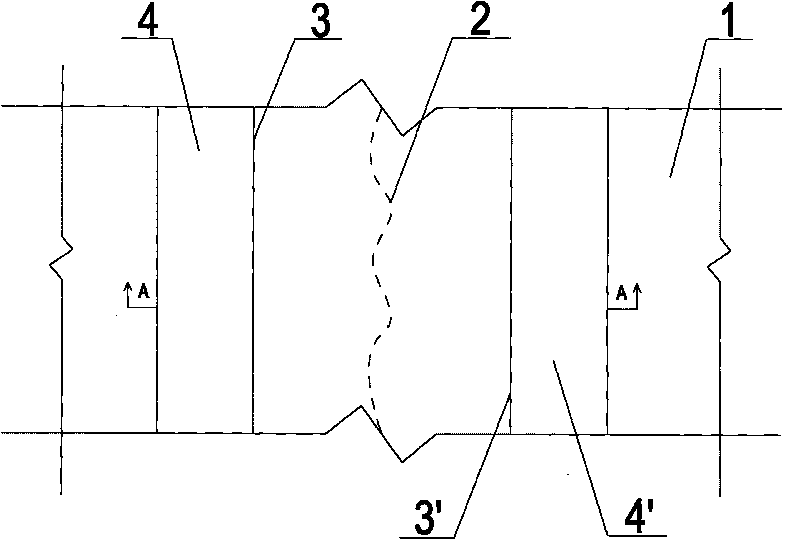

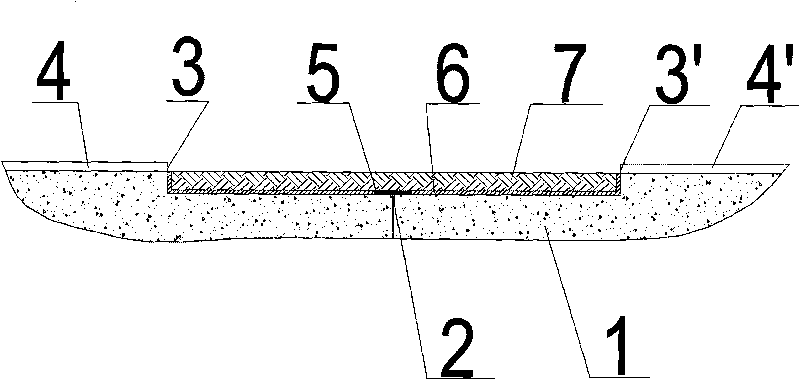

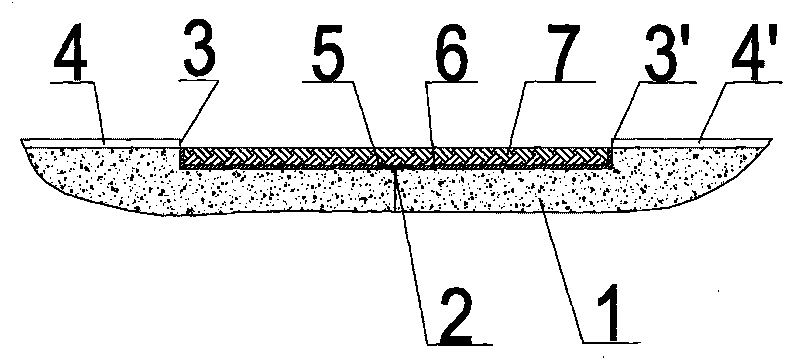

[0027] (1) marking line: such as figure 1 and figure 2 As shown, on the channel concrete panel 1, take the irregular crack 2 as the center line, draw two marking lines 3, 3' on both sides, and the distance between the marking lines (that is, the width of the groove) is 6 cm, so as to ensure the crack bonding width and suitable seepage path.

[0028] (2) Groove grinding: Use a...

Embodiment 2

[0036] In this embodiment, the width of the crack 2 is 3-5 mm, and the primer 6 and elastic anti-seepage material 7 used are SK polyurea and the matching SK-BE14 primer produced by Beijing Kehaili New Building Material Development Co., Ltd. agent, its performance parameters: tensile strength 10.3MPa, elongation at break 276%, bonding strength 2.1Mpa, primer dosage 250g / m 2 ; Groove width 5cm, depth 4mm, the vertical and horizontal groove transitions in a circular arc, the radius of curvature of the circular arc is 0.6mm; stick a layer of plastic adhesive tape along the surface of the crack 2 as the isolation layer 5, and the width is 7mm; other implementations are the same example 1.

Embodiment 3

[0038] In this embodiment, the width of the crack 2 is 0.1-1 mm, and the elastic material used is SF-1 polysulfide sealant produced by Henan Sida Engineering Technology Co., Ltd. and the matching primer. Its performance parameters: tensile strength 2.1MPa, elongation at break 260%, bonding strength 1.6Mpa, primer dosage 400g / m 2 ; Groove width 12cm, depth 2mm, the vertical and horizontal groove transitions in a circular arc, the radius of curvature of the arc is 0.3mm; paste a layer of kraft paper adhesive tape along the surface of the crack 2 as the isolation layer 5, and the width is 10mm; other implementations are the same example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Crack width | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Adhesive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com