Preservative film

A technology of plastic wrap and polyvinylidene chloride, which is applied in the direction of flexible coverings, packaging, wrapping paper, etc., can solve the problems of low friction and non-discovery, and achieve the effect of low friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] 3. Preparation of Resin

[0039] The preparation of the resin to form a wrap film can be performed by a conventional method, respectively.

[0040] [Preparation of polyvinylidene fluoride-based resin]

[0041] For example, the polyvinylidene chloride-based resin preferably used as a resin for forming a fresh-keeping film is more preferably composed of 60 to 99 mass percent of vinylidene chloride and 40 to 1 mass percent of comonomer (commonomer of vinylidene chloride and comonomer) The total amount is 100% by mass) and the vinylidene chloride copolymer formed can usually be prepared by suspension polymerization or emulsion polymerization of predetermined amounts of vinylidene chloride and comonomer. The suspension polymerization method is a method in which mixed and dispersed oil droplets of vinylidene chloride and a comonomer are formed by mechanical stirring in an aqueous solvent containing a suspending agent, and polymerization is carried out using a polymerization in...

Embodiment 1

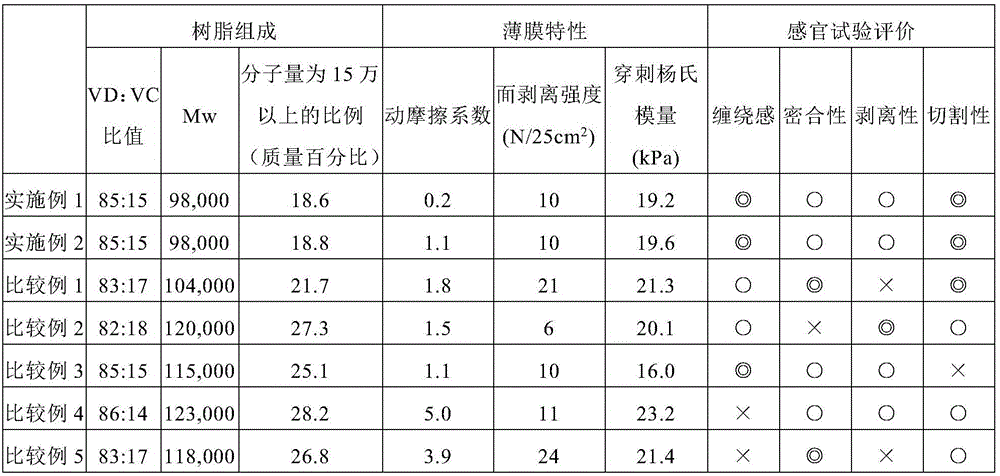

[0132] Using a single-screw extruder with a diameter of 90mm equipped with a vacuum hopper, melt-extrude the vinylidene chloride-vinyl chloride copolymer prepared according to a conventional method at a temperature of 180°C into a ring shape, and in a cooling tank at a temperature of 10°C After rapid cooling in , blow molding biaxial stretching was carried out at room temperature to obtain a plastic wrap with a thickness of 10 μm. In the vinylidene chloride-vinyl chloride copolymer in the plastic wrap, the mass ratio of vinylidene chloride:vinyl chloride (hereinafter sometimes referred to as "VD:VC ratio") is 85:15, and when the molecular weight is measured, the weight average The molecular weight (hereinafter sometimes referred to as "Mw") was 98,000, and the ratio of molecular chains with a molecular weight of 150,000 or more (hereinafter sometimes referred to as "the ratio of molecular weight of 150,000 or more") was 18.6% by mass. Hereinafter, the ratio of VD:VC, Mw, and m...

Embodiment 2

[0135] The composition of the vinylidene chloride-vinyl chloride copolymer was changed to obtain a plastic wrap. The VD:VC ratio of the vinylidene chloride-vinyl chloride copolymer in the cling film was 85:15, Mw was 98,000, and the proportion with a molecular weight of 150,000 or more was 18.8% by mass. Table 1 shows the film characteristics and sensory test evaluation results of this wrap film together with the resin composition.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com