Multiple-sided cmp pad conditioning disk

a technology of conditioning disk and cmp pad, which is applied in the direction of grinding drive, grinding surface conditioning device, manufacturing tools, etc., can solve the problems of increased requirements for high-precision surface quality of wafers, unusability of wafers, and undesirable surface irregularities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

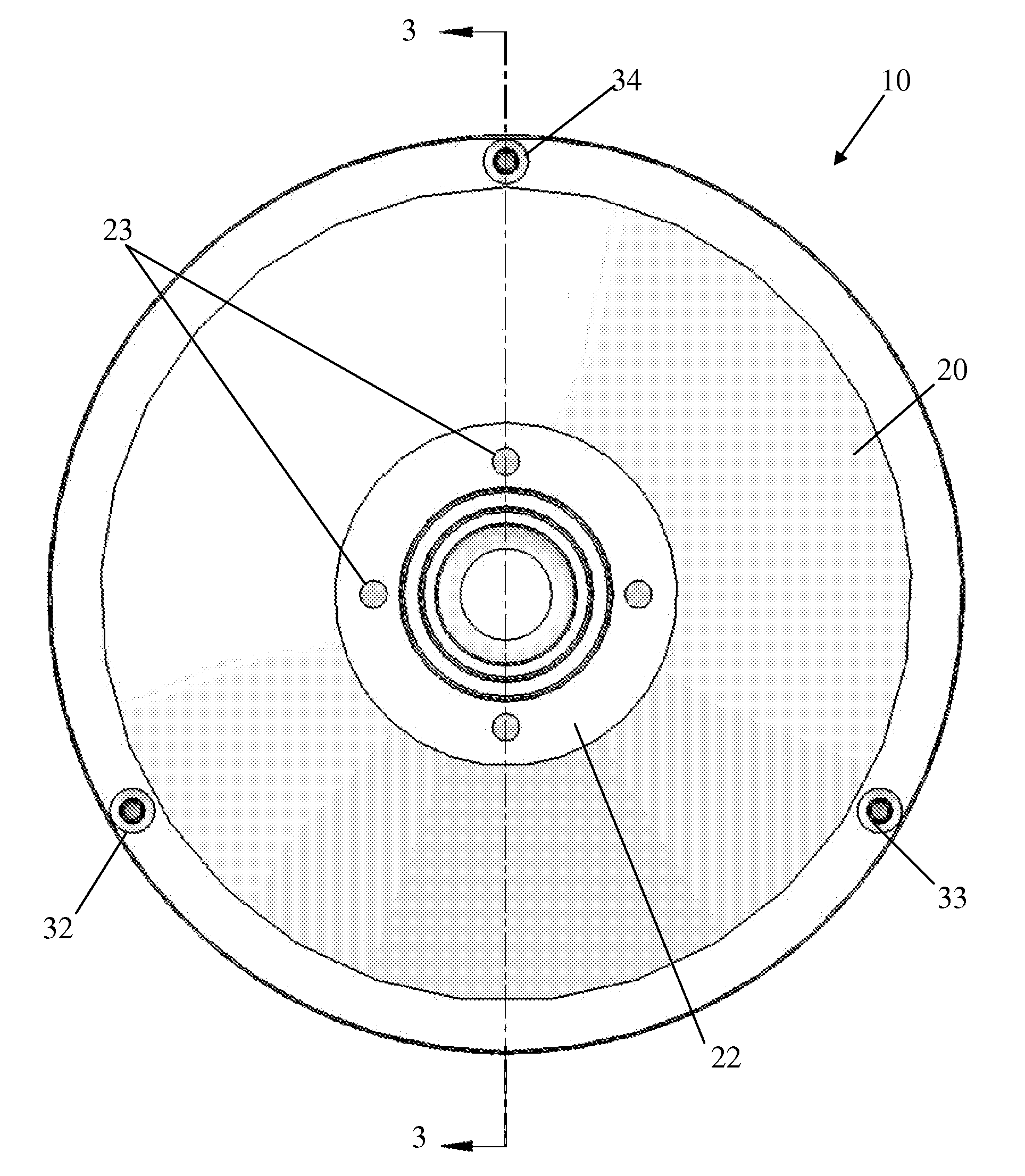

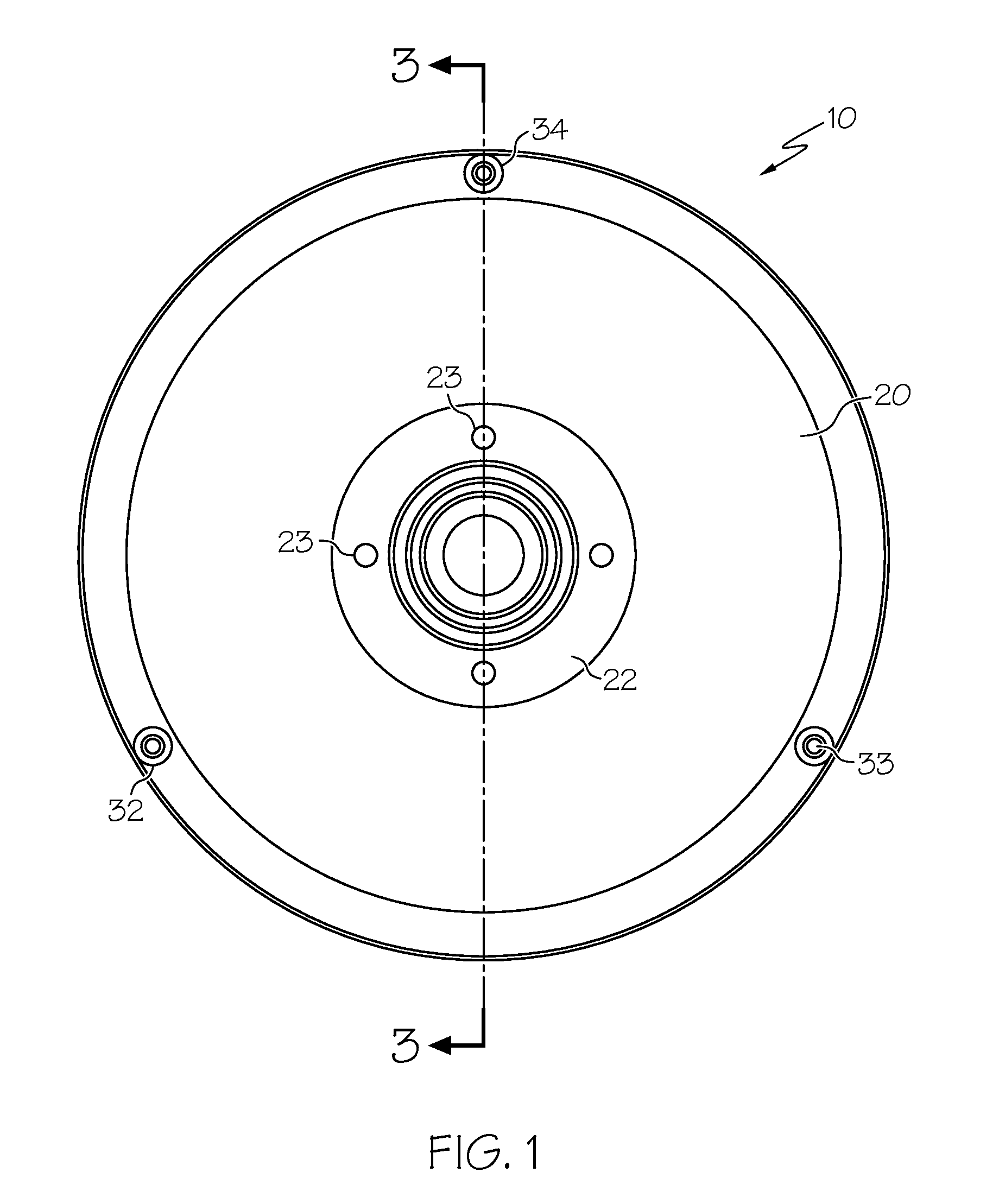

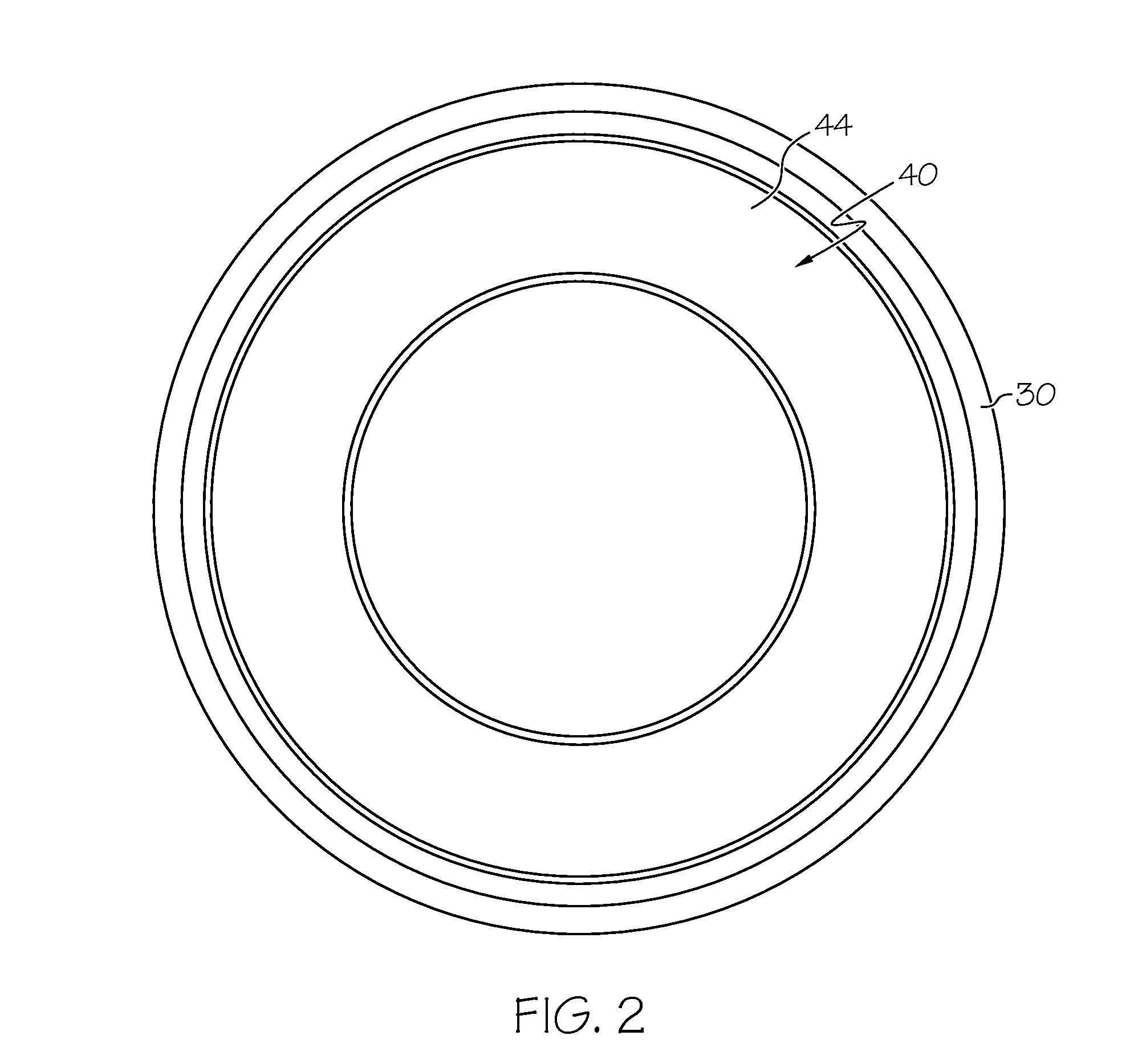

[0049]The preferred embodiment of the present invention includes the following major components that are illustrated in FIGS. 1-10. A holder 10 is made up of a base 20 and a ring 30 that attaches to the base 20. The base 20 is designed to be attached to a drive mechanism (not shown), such as a rotatable drive motor. The ring 30 rigidly and firmly attaches to the base 20 using fasteners, such as screws or magnets. A disk 40 is mounted between the ring 30 and the base 20, and is held in place in a tight, non-rotatable connection preferably by structures located at the peripheral edge of the disk 40 and the ring 30 or base 20 that interlock to prevent relative movement of the disk 40 and the holder 10. In this manner, the disk 40 is held firmly in place in the holder 10, and is driven rotatably thereby without substantial relative rotational movement between the disk 40 and the holder 10. This permits the disk surface to be placed in contact with a CMP polishing pad for conditioning th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Force | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Abrasive | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com