Hydrotreating method of product circulation

A hydrogenation treatment and product technology, applied in chemical instruments and methods, chemical/physical processes, refining to remove heteroatoms, etc., can solve problems such as ineffective treatment of sulfur and reduced reaction efficiency, to eliminate the influence of wetting factors, Reduce side reactions such as cracking and increase specific heat capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

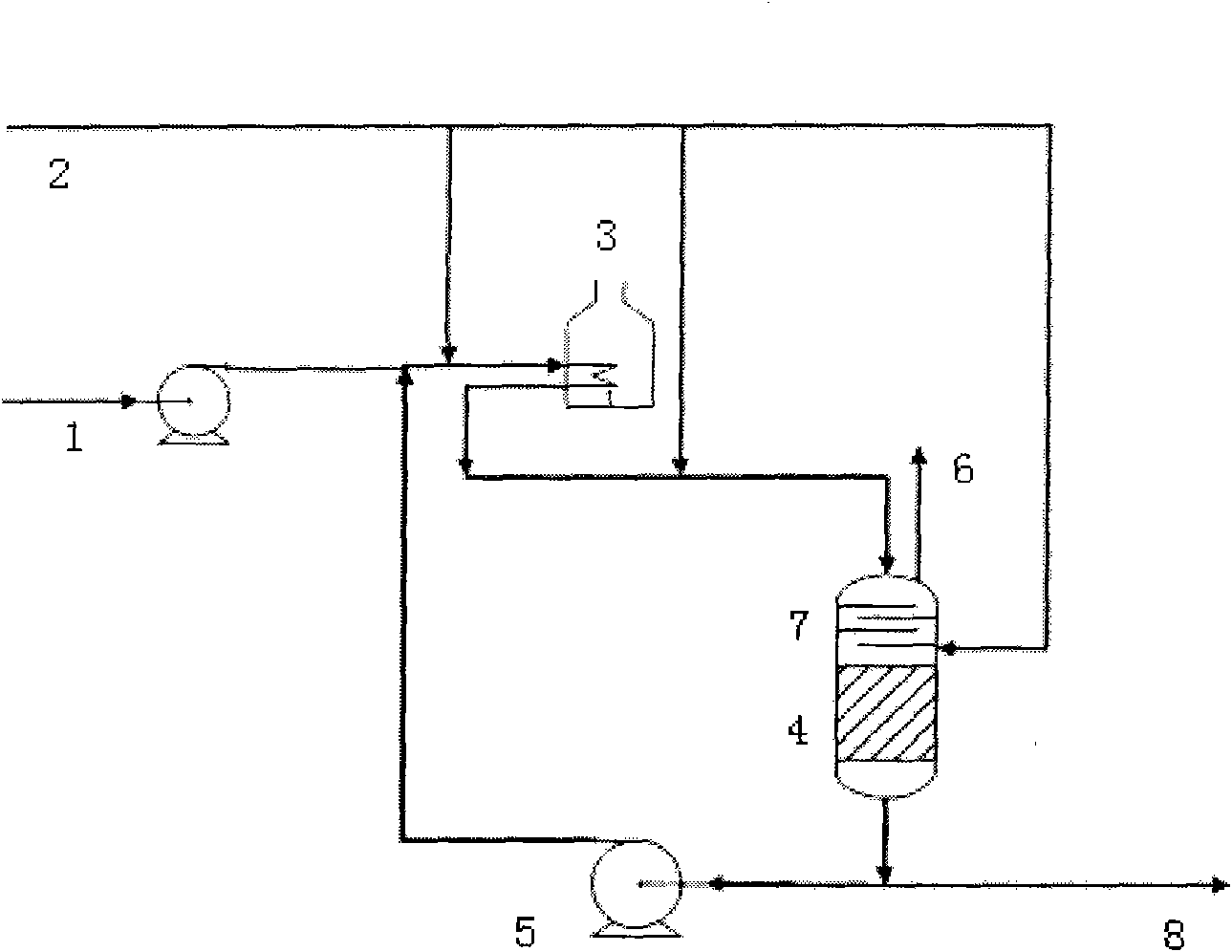

Method used

Image

Examples

Embodiment

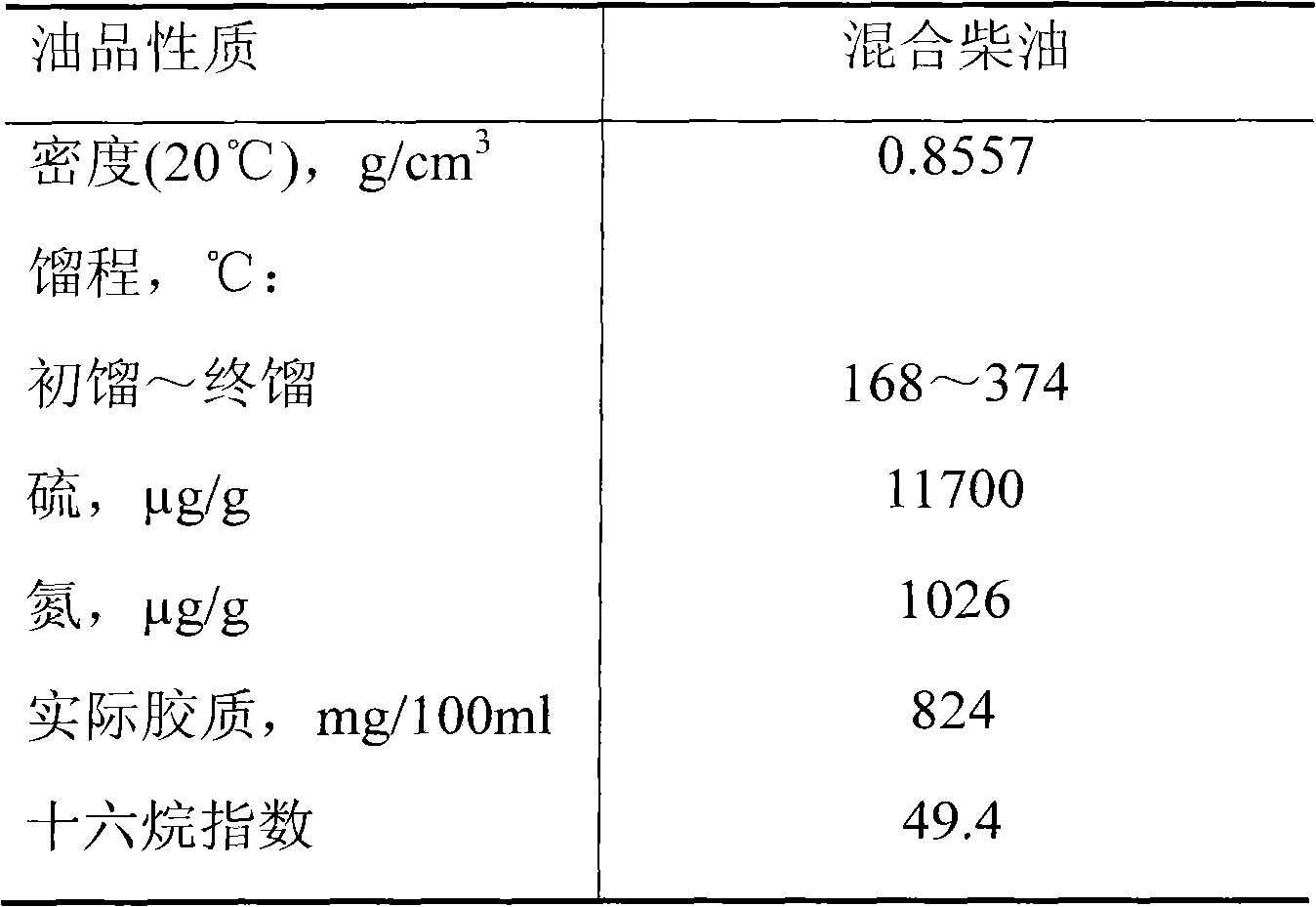

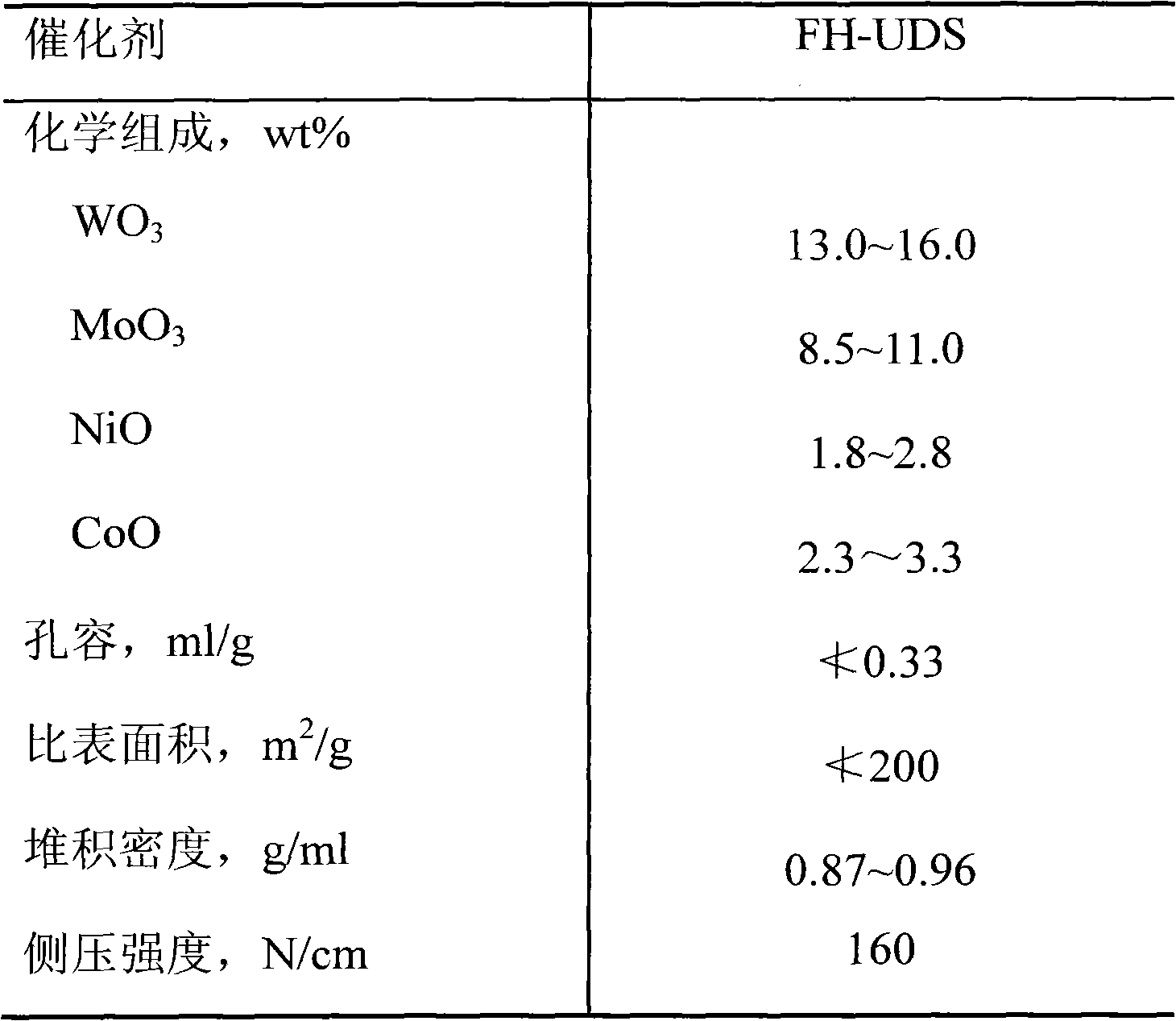

[0029] According to the present invention, the properties of the raw materials used are shown in Table 1-1, and the catalyst is FH-UDS hydrorefining catalyst developed and produced by Fushun Petrochemical Research Institute. The composition and quality index of FH-UDS catalyst are shown in Table 1-2, the process conditions are shown in Table 1-3, and the properties of refined diesel oil are shown in Table 1-4. Three bubble-cap trays are arranged on the upper part of the reactor, and the gas-liquid volume ratio of stripping is 5:1.

[0030] Table 1-1 Properties of Raw Oil

[0031]

[0032] Table 1-2 Composition and quality index of catalyst

[0033]

[0034] Table 1-3 Process conditions

[0035]

[0036] Table 1-4 Properties of refined oil

[0037]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com