Conversion method for petroleum hydrocarbons

A technology for petroleum hydrocarbons and gasoline, applied in the field of catalytic cracking, which can solve problems such as improving product distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

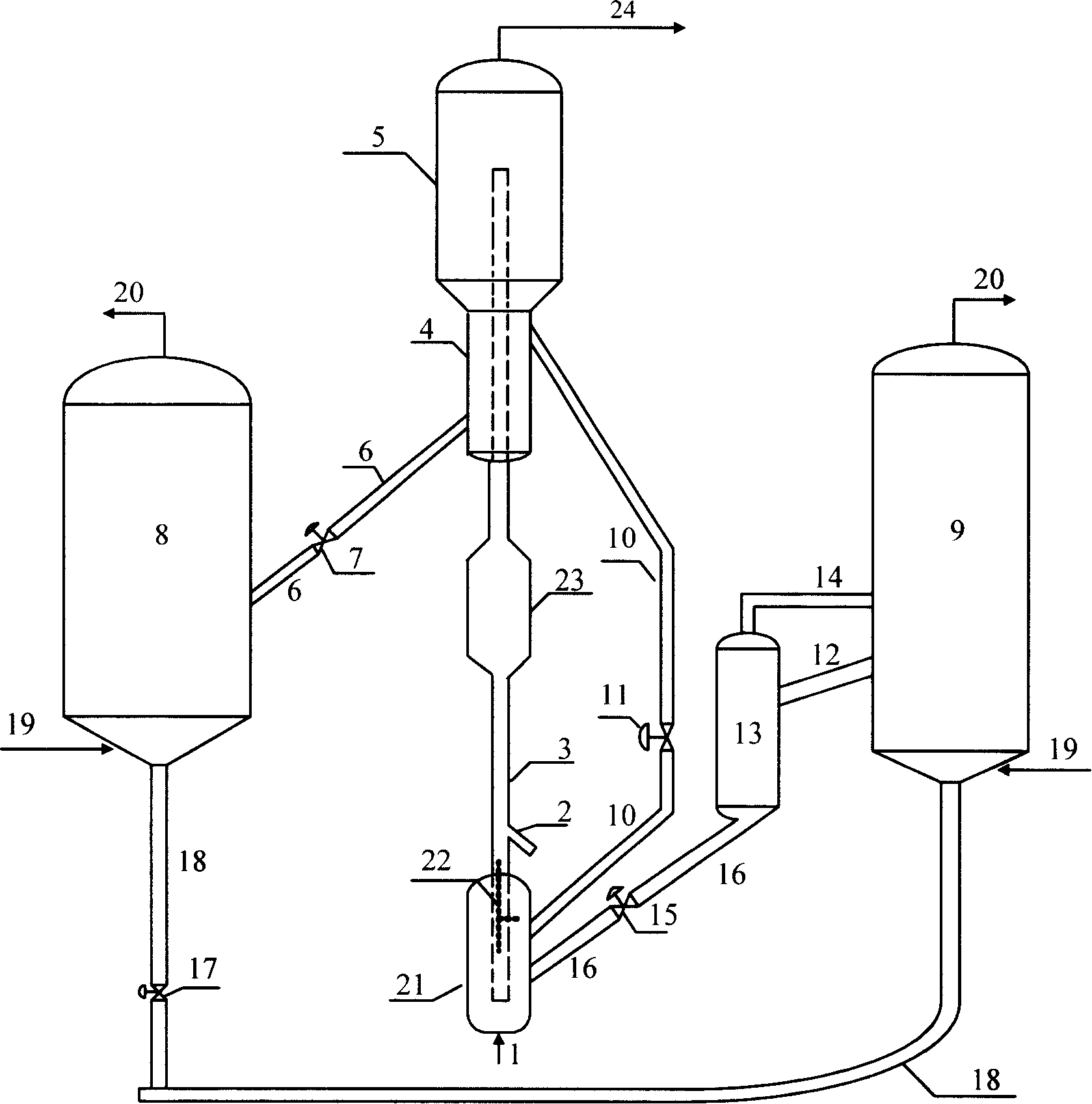

[0043] This example illustrates the distribution of products obtained by adopting the method provided by the present invention and using different operating conditions for straight-run wax oil on a medium-sized catalytic cracking unit.

[0044] The flow chart of the medium-sized catalytic cracking unit is as follows: figure 1 As shown, the feed oil M listed in Table 2 is used as the raw material, and the preheated feed oil M is injected into the riser reactor through the pipeline 2, and is in contact with the mixed catalyst of catalyst A listed in Table 1. The raw catalyst and the 700°C regenerated catalyst are mixed at a ratio of 0.1:1. The reaction temperature in the first reaction zone of the riser reactor is 515°C, the pressure at the top of the reactor is 0.2 MPa, and the reaction time is 1.2 seconds; The reaction temperature in the second reaction zone is 500° C., and the reaction time is 4 seconds. The agent-to-oil ratio of the device is 9.6:1. The reaction product, s...

Embodiment 2

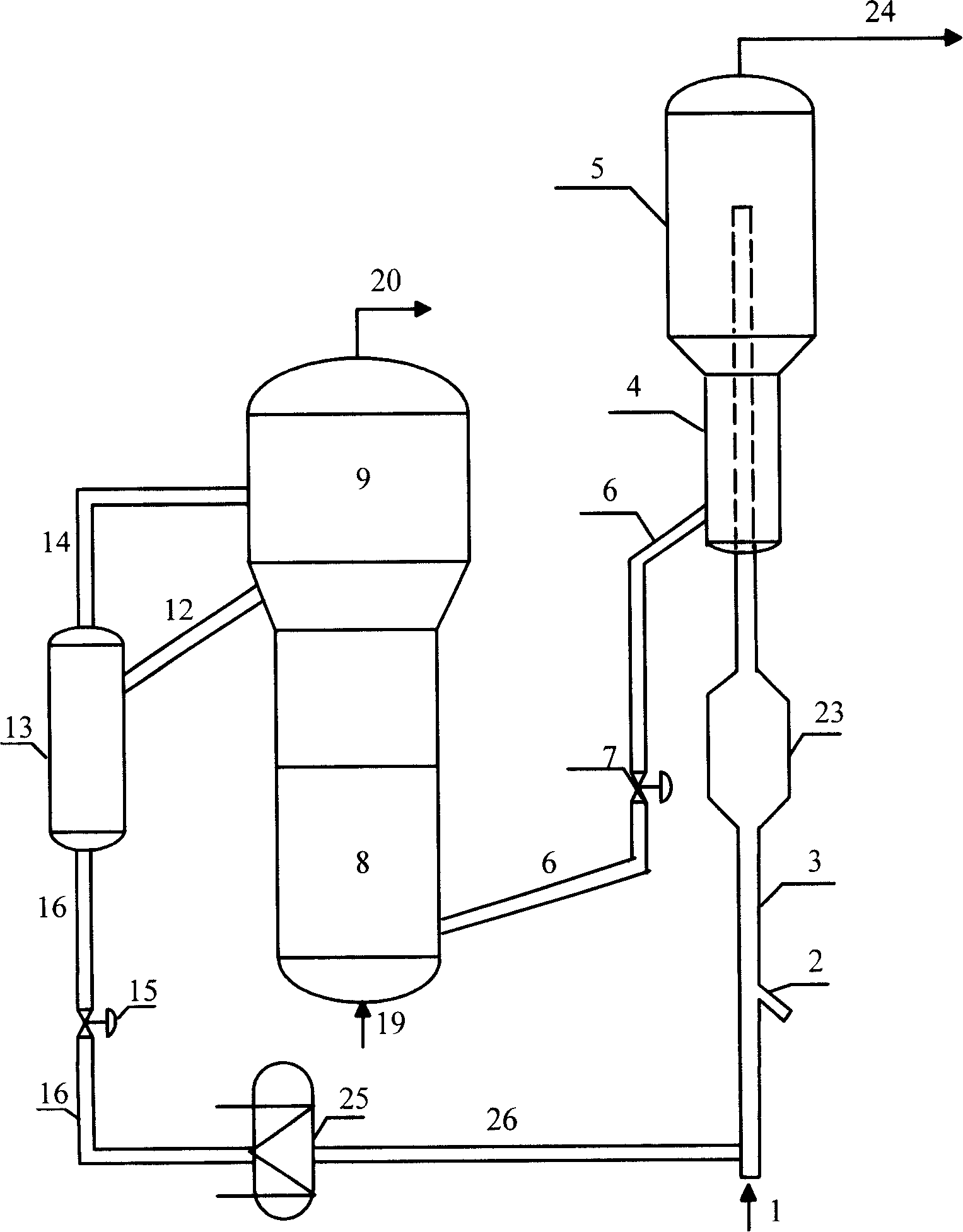

[0050] This example illustrates the reaction of atmospheric residual oil in a medium-sized catalytic cracking unit by adopting the method provided by the present invention.

[0051] The flow chart of the medium-sized catalytic cracking unit is as follows: figure 2 As shown, the feed oil N listed in Table 2 is used as the raw material, and the preheated feed oil N is injected into the riser reactor through the pipeline 2, and is in contact with the catalyst B listed in Table 1. The regenerated catalyst B is cooled at 650°C Regenerated catalyst, the reaction temperature in the first reaction zone of the riser reactor is 515 ° C, the pressure at the top of the reactor is 0.2 MPa, the reaction time is 1.2 seconds, the reaction temperature in the second reaction zone is 500 ° C, and the reaction time is 4 seconds. Under the catalytic conversion reaction. The reaction product, steam and raw catalyst are separated in the settler, and the reaction product is separated to obtain gas ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com