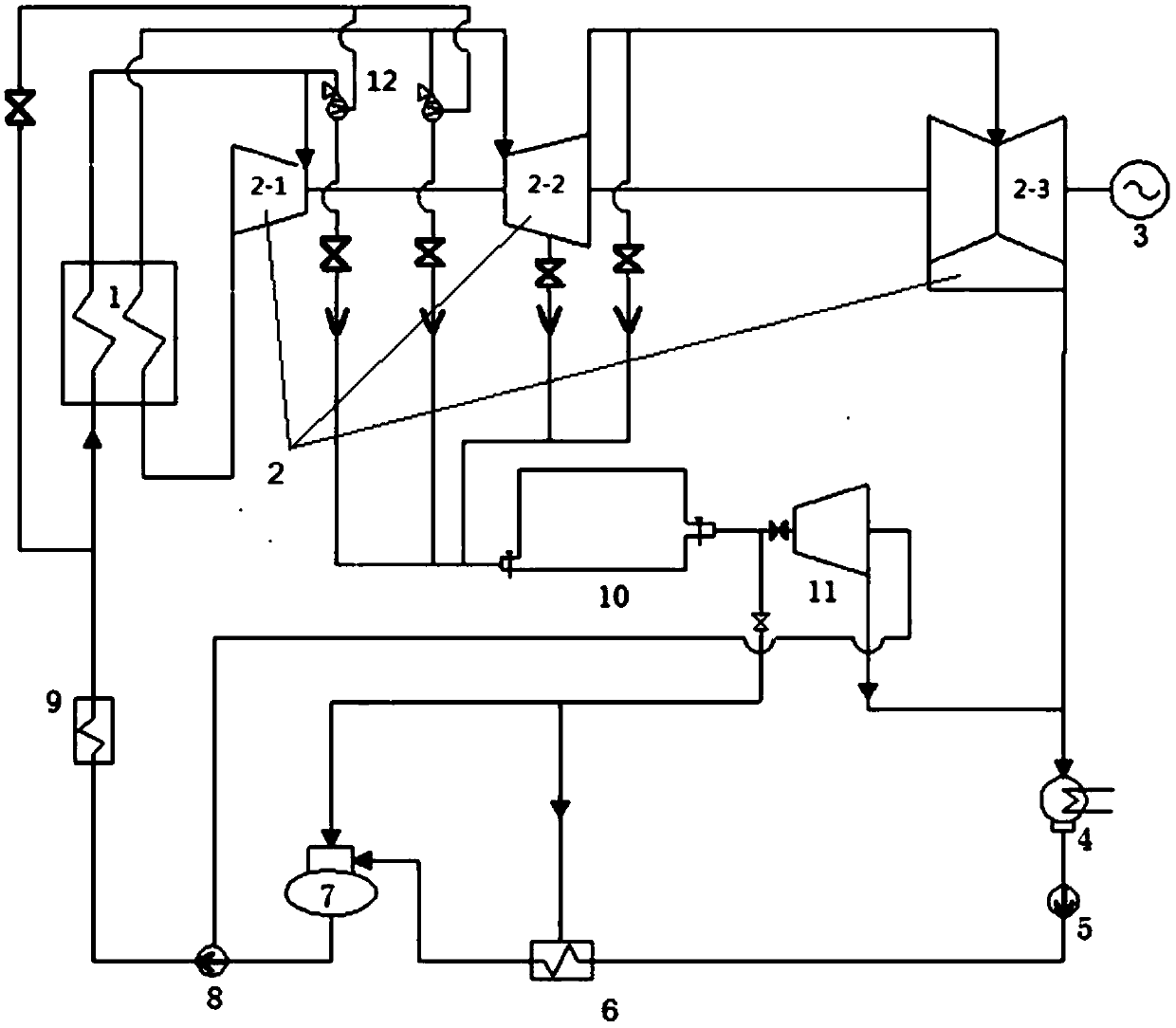

Heat regenerative system capable of improving unit peak load regulation capacity and dynamic calculation method of heat regenerative system heat storage tank steam temperature

A technology for a regenerative system and a heat storage tank is applied in the field of dynamic calculation of the steam temperature of the regenerative system and the heat storage tank of the regenerative system, and can solve the problems of poor peak shaving capability and flexibility of thermal power units.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

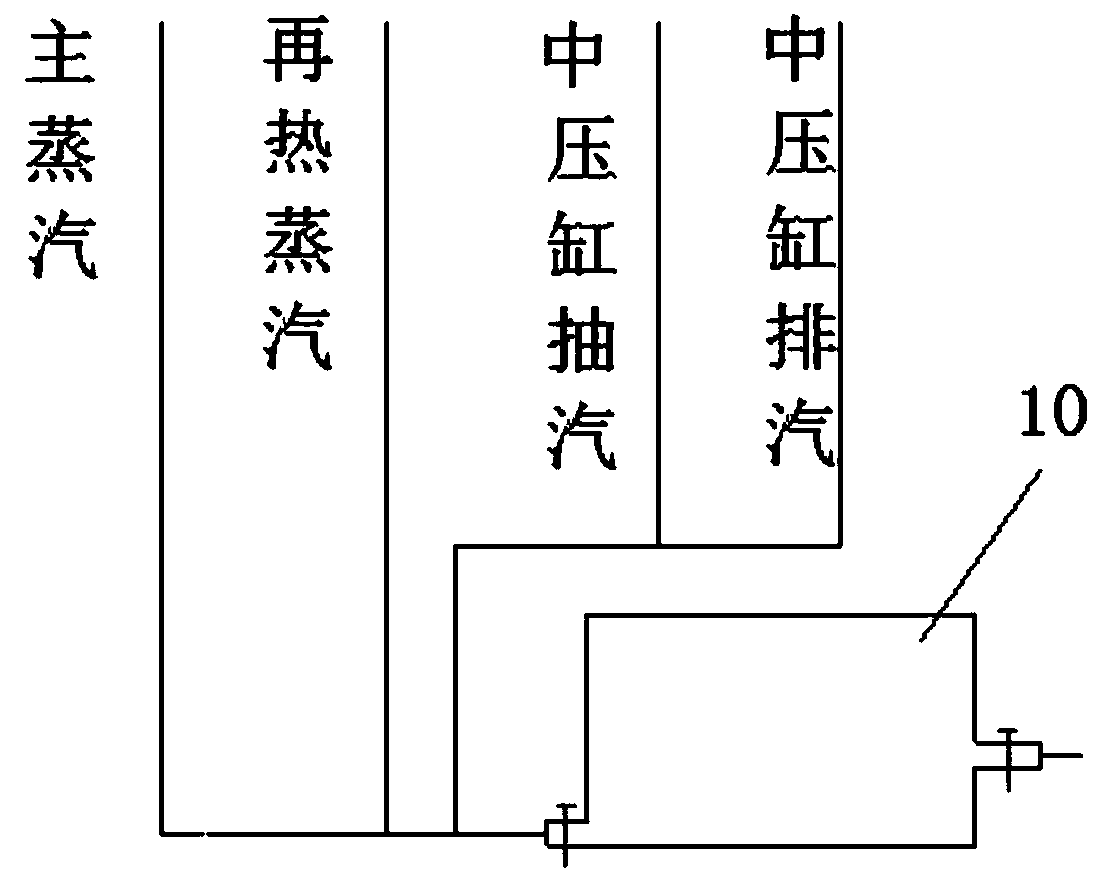

Method used

Image

Examples

example

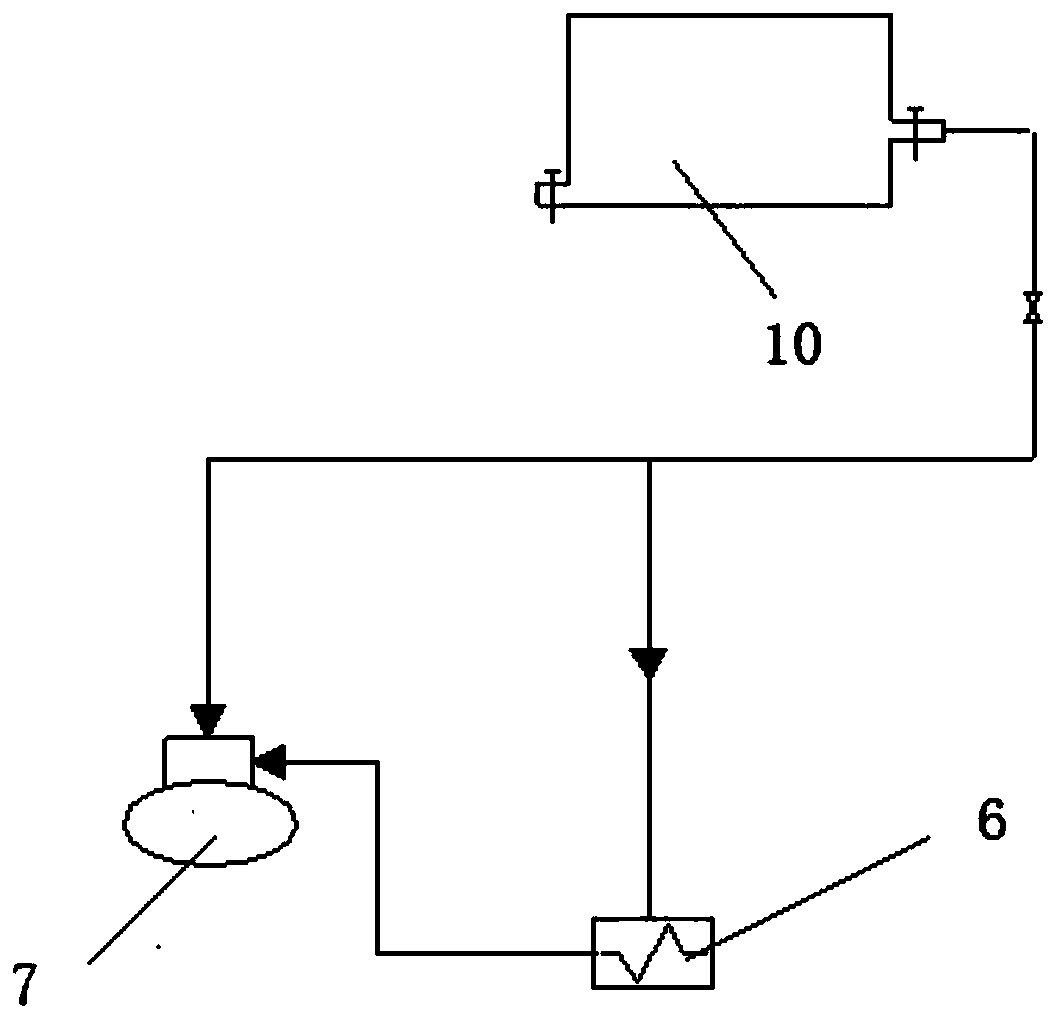

[0241] Transform the formula (29) to get the following formula

[0242]

[0243] In the formula: dT is the change of steam temperature in the heat storage tank, ℃; dτ is the micro-increment of time, s; Δτ is the time interval, s; T 0 is the initial temperature of the heat storage tank, °C; T 1 is the temperature after the Δτ time interval, °C. q m,in is the mass flow rate of steam flowing into the heat storage tank, kg / s; m 1 for T 1 Steam mass of heat storage tank at any time, kg; h 0 is the steam enthalpy flowing into the heat storage tank, kJ / kg; h 2 is the exhaust enthalpy of small steam turbine, kJ / kg; c v Specific heat capacity for constant volume of steam in heat storage tank, kJ / (kg °C); c P is the specific heat capacity of steam at constant pressure in the heat storage tank, kJ / (kg °C), and γ is c P with c v Ratio.

[0244] Further derivation can be obtained:

[0245]

[0246] In the formula: T 0 is the initial temperature of the heat storage tank, ℃...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com