Aerating, collecting and exhausting combining system in solid-state-composting aerobic fermentation and application thereof

A combined system and composting technology, applied in the field of fermentation process control, can solve the problems of high airtight cost, large ventilation volume, high wind pressure, etc., and achieve the effect of reducing purchase cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

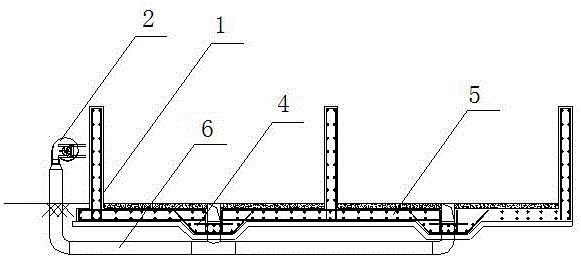

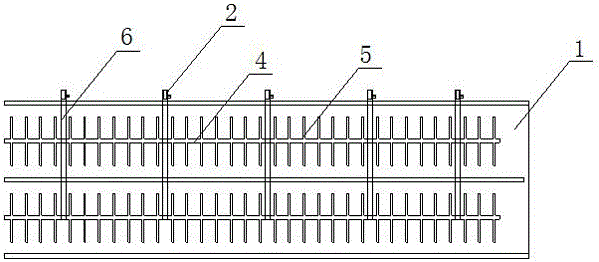

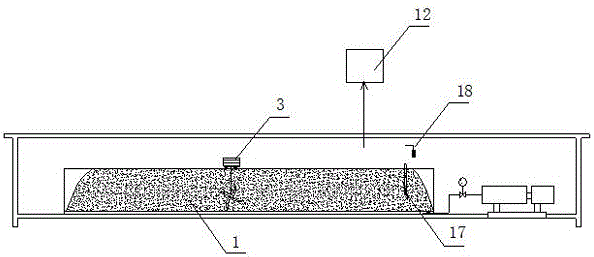

[0035] Such as Figure 1-8 As shown, the combined system of aeration, collection and exhaust in the aerobic fermentation of solid compost includes fermentation tank 1, medium pressure fan unit 2, turning machine 3, main aeration ditch 4, fishbone type branch aeration ditch 5. Aeration and ventilation pipe 6, aeration plate 7, membrane sealing structure 8 and independent exhaust structure; turning and throwing machine 3 is set in fermentation tank 1; one end of fermentation tank 1 is sealed with concrete, and the concrete closed end of fermentation tank 1 A medium-pressure fan unit 2 is provided, and the bottom of the fermentation tank 1 is provided with a main aeration ditch 4, and opposite sides of the main aeration ditch 4 are provided with herringbone type branch aeration ditch 5, and the top of the herringbone type branch aeration ditch 5 is An aeration plate 7 is provided, and the aeration ventilation pipe 6 is arranged at the bottom of the fermentation tank 1, and the ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com