Hydraulic pressure driven membrane pump with leakage compensation equipment

A diaphragm pump and diaphragm technology, applied to pumps with flexible working elements, mechanical equipment, pumps, etc., can solve problems such as suction limit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

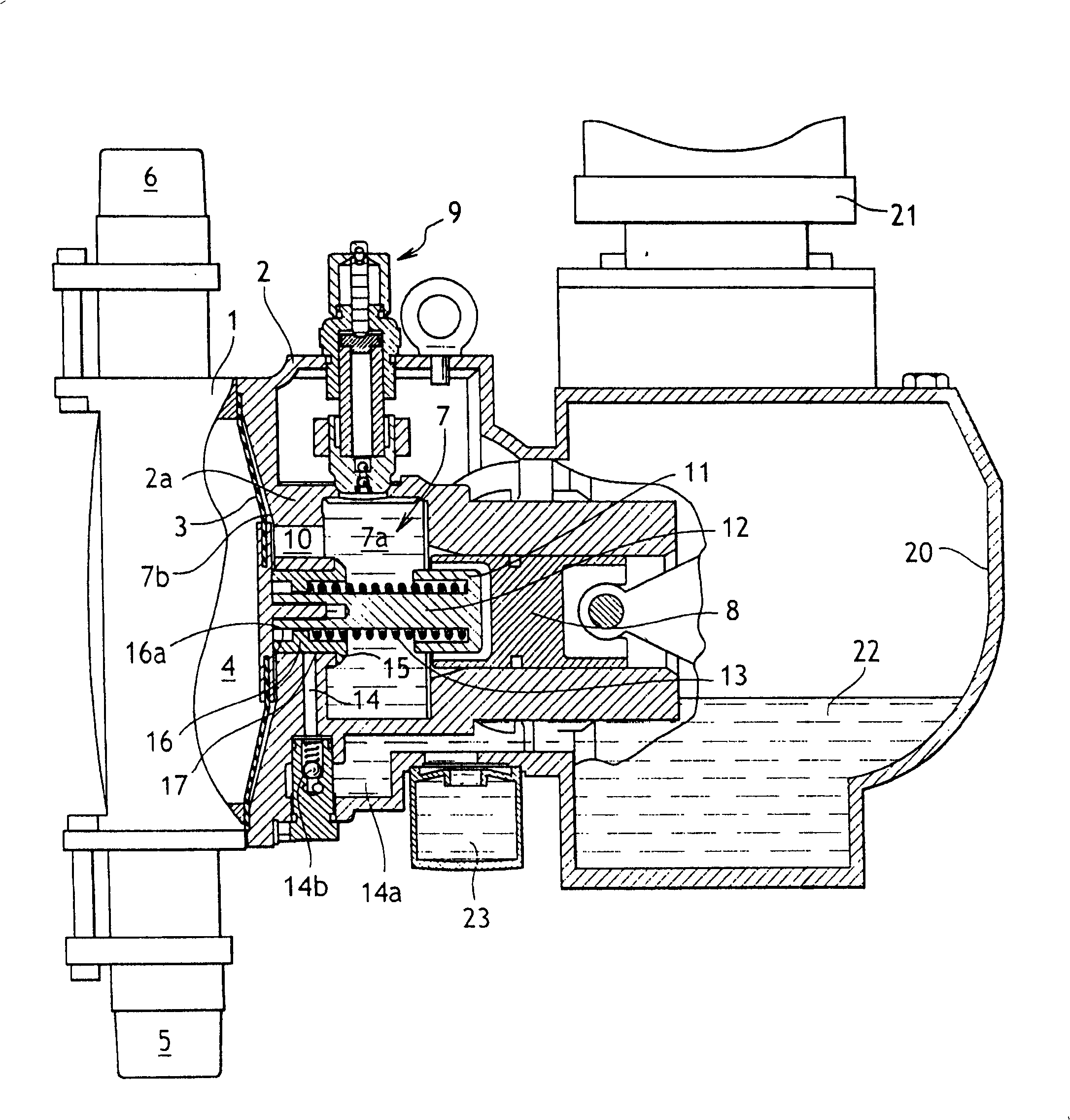

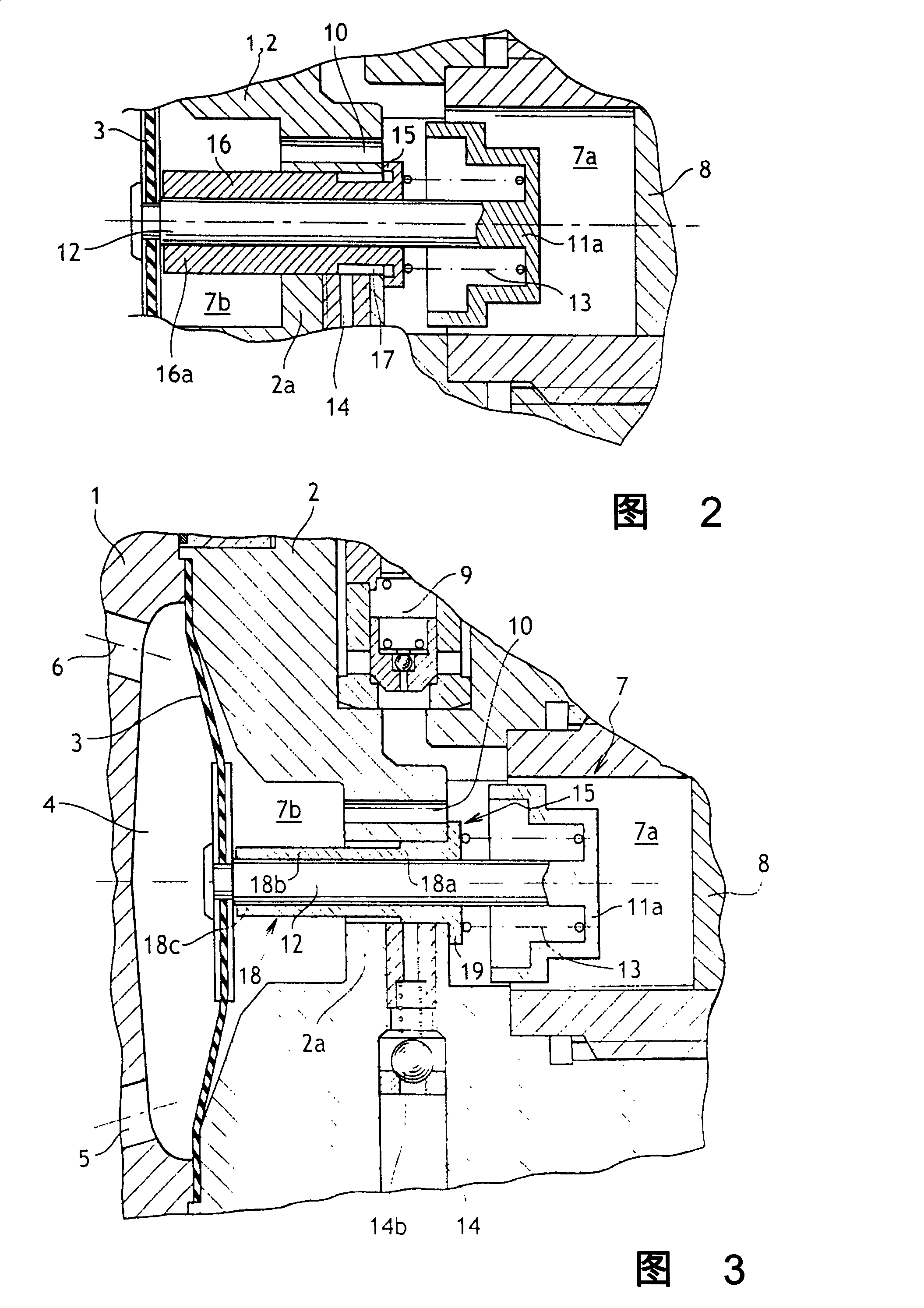

[0024] Typically, a hydraulically controlled diaphragm pump comprises a pump body consisting of two parts 1 and 2 with a perimeter of a diaphragm 3 sandwiched between them.

[0025] The diaphragm and part 1 of the body together define a pump chamber 4 in which both the suction conduit 5 and the delivery conduit 6 terminate and are fitted with non-return valves (not shown).

[0026] The diaphragm and part 2 of the body together define a cavity 7 filled with hydraulic fluid which can be cyclically displaced forwards (to the left of the figure) or backwards by a reciprocatingly driven piston 8 . This provides hydraulic control over the change in volume of the pump chamber 4 .

[0027] The chamber 7 is also usually fitted with a safety valve 9 for limiting the delivery pressure to a predetermined safety value and which is usually used in conjunction with means for evacuating the control fluid.

[0028] exist figure 1 , it should be observed that cavity 7 has two parts. The gene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com