Water feeding device for endoscope

a technology of endoscopy and water feeding, which is applied in the field of water feeding devices for endoscopy, can solve the problems of wasting time, affecting the safety of endoscopy, and affecting the safety of endoscopy, and achieves the effect of easy proper injection and high sanitary sta

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

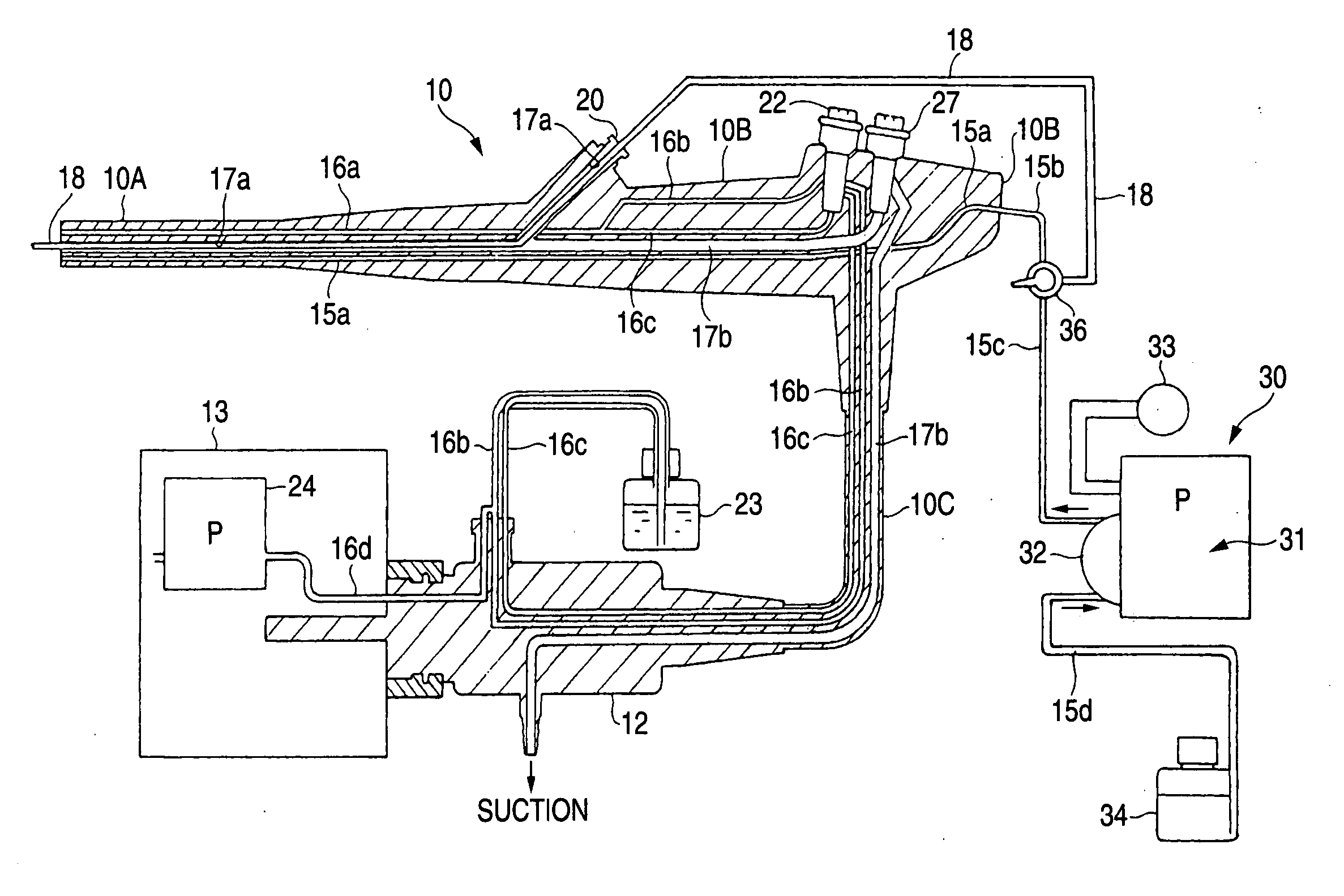

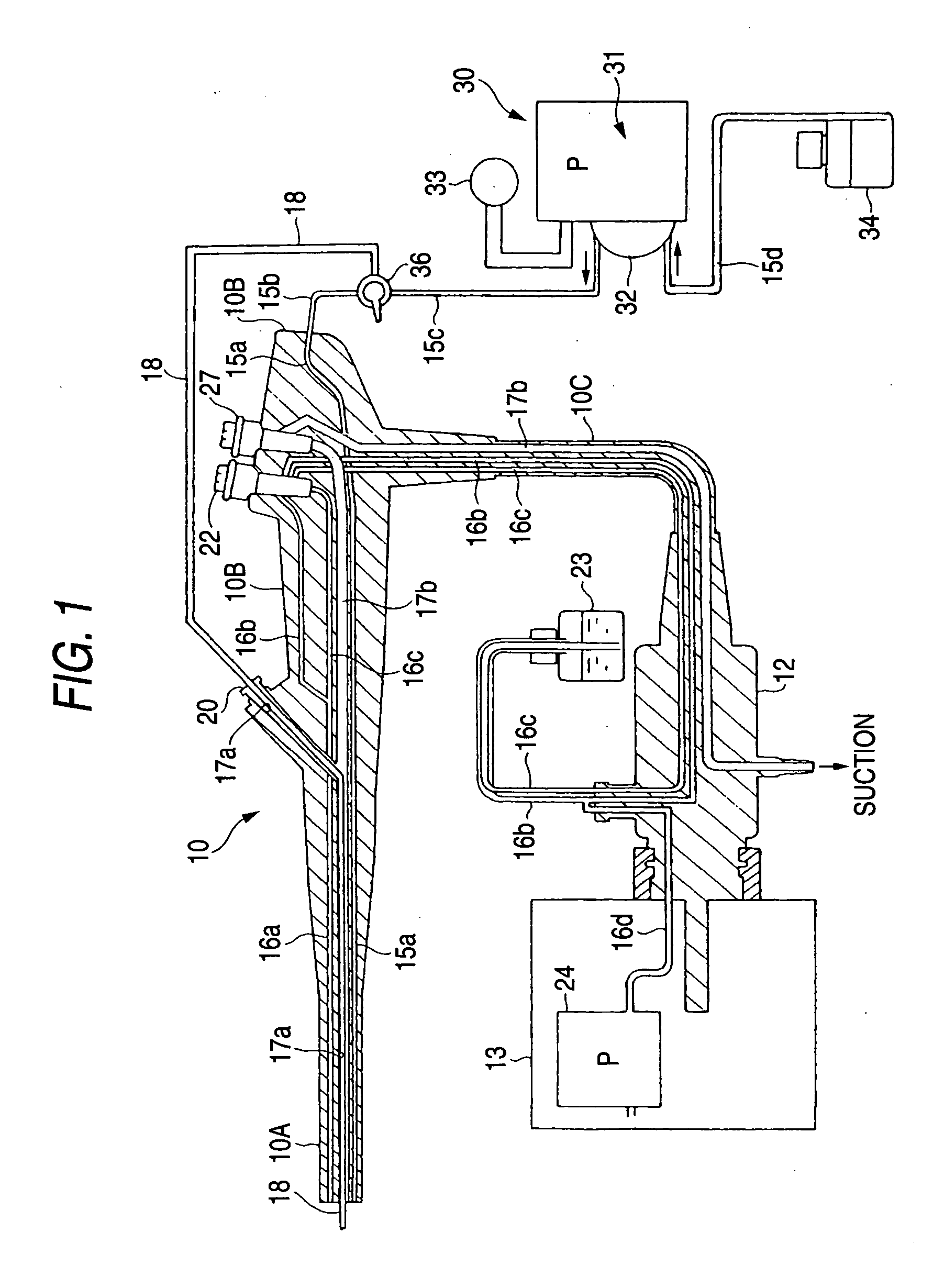

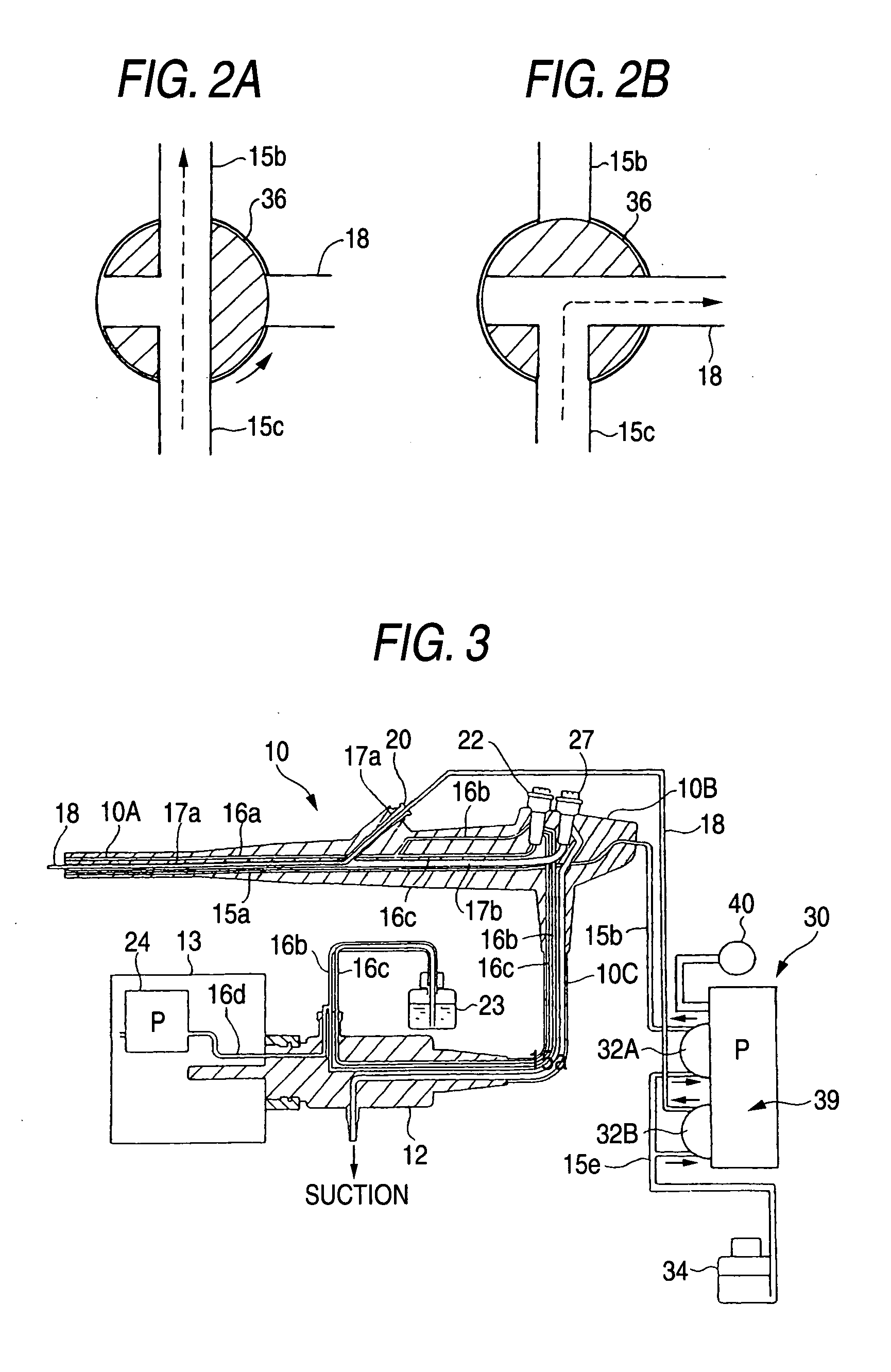

[0051]FIGS. 1 and 2 show the construction of a water feeding device for an endoscope according to an embodiment 1-1. As shown in FIG. 1, an endoscope (electronic endoscope) 10 has an insertion portion 10A, an operating portion 10B and a cable portion 10C, and it is connected to a light source device 13 shown in FIG. 1 by a connector 12 of the cable 10C. In the case of the electronic endoscope, the cable 10C is also connected to a processor device. Various kinds of pipe lines are provided in the endoscope 10. A water jet pipe (dedicated water feeding pipe line) 15a is disposed so as to extend from the tip of the insertion portion 10A to the rear end portion of the operating portion 10B. An air-feeding / water-feeding pipe 16a is provided at the tip side to clean an observation window (lens face) of an object optical system equipped to the tip of the insertion portion 10A through a nozzle, and an air-feeding pipe 16b and a water feeing pipe 16c are provided so as to intercommunicate wit...

embodiment 2

[0067] The overall construction of the water feeding device for an endoscope according to the embodiment 2 is same as in the embodiment 1 (See FIG. 1).

[0068]FIG. 9 shows the detailed construction of the water feeding pump portion 30 and the tank 34 on the embodiment 2. As shown in FIG. 1, a power supply switch 44, a connection portion 45 of a foot switch 33, etc. are provided in the main body 31 of the water feeding pump portion (device) 30. In addition, the connection pipe 15d at the tank side is connected to the input port pipe 46 of the pump 32, and a liquid take-out pipe 53 of the tank 34 is connected to the connection pipe 15d through a Luer lock 50. The connection pipe 15c to be connected to the endoscope side is connected to the output port pipe 47 of the pump 32.

[0069] In the embodiment 2, an orifice 55 for setting the maximum water feeding pressure in the pipe is provided to the output port pipe 47 of the pump 32. FIGS. 10A and 10B show the construction of the orifice 55....

embodiment 3

[0077] The overall construction of the water feeding device for an endoscope according to the embodiment 3 is same as in the embodiment 1 (See FIG. 1).

[0078]FIG. 13 shows the detailed constructions of the water feeding pump portion 30, the liquid bag and the tank 34 on the embodiment 3. As shown in FIG. 1, the main body 31 of the water feeding pump portion (device) 30 is equipped with a power supply switch 44, a connection portion 33C of a foot switch 33, a flow rate adjusting finger grip (variable resistor) 245, etc. The connection pipe 15d at the tank side is connected to the input port pipe 46 of the pump 32, and the connection pipe 15c at the endoscope side is connected to the output port pipe 47 of the pump 32. A Luer connection type (male and female screw fixing type) female connector 50 is secured to the tip of the connection pipe 15d, and a male screw portion of the injection needle 52 and the female connector 50 screw together.

[0079] In the embodiment 3, a liquid bag 54 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com