Method and apparatus for power generation using waste heat

a technology of waste heat and power generation, applied in lighting and heating equipment, machines/engines, greenhouse gas reduction, etc., can solve the problems of changing the buoyancy characteristics of the vessel by consumption of liquid fuel, and achieve the reduction of the required size of the exhaust duct of the marine power plant, the reduction of the required size of the exhaust duct, and the increase of the exhaust gas density.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

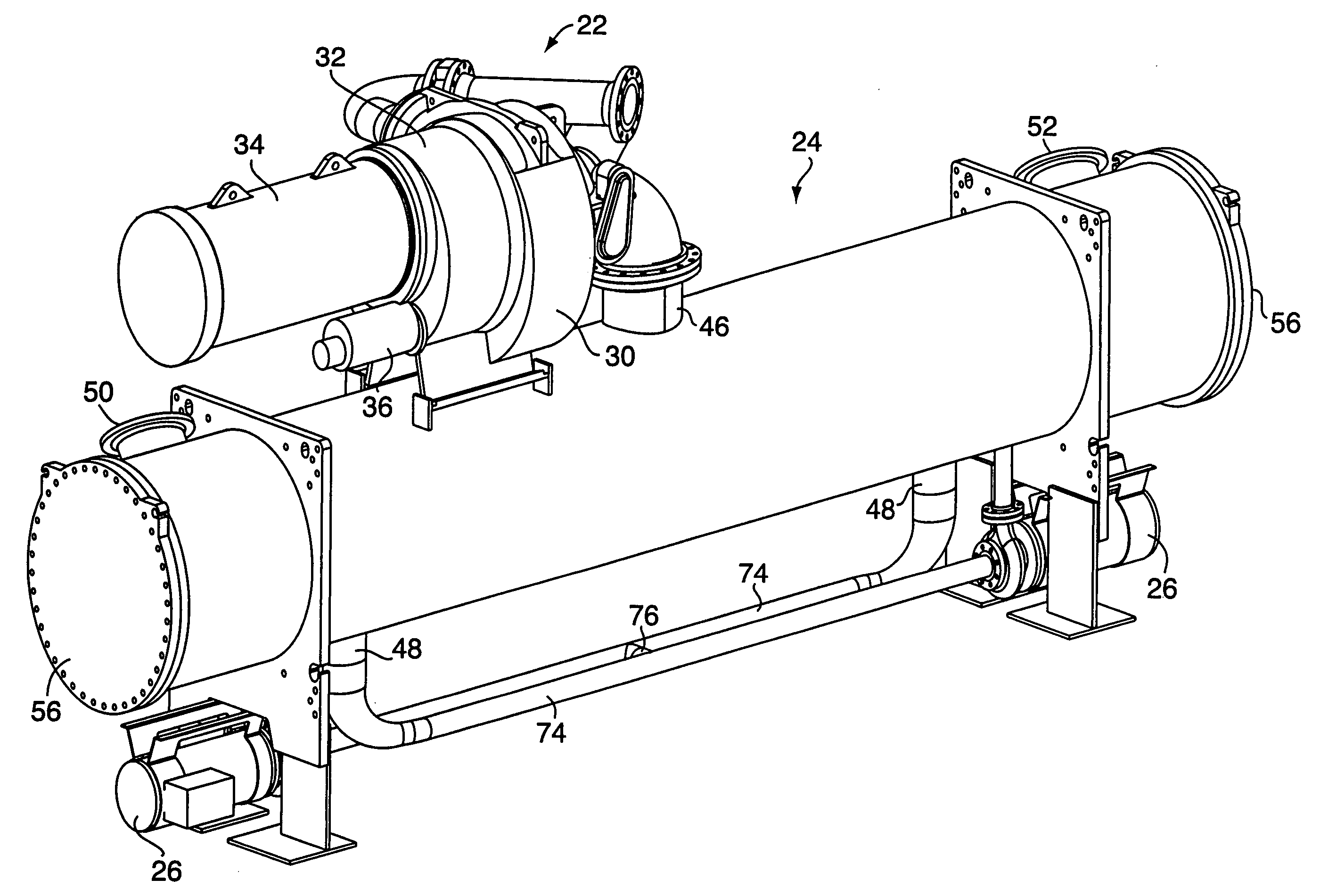

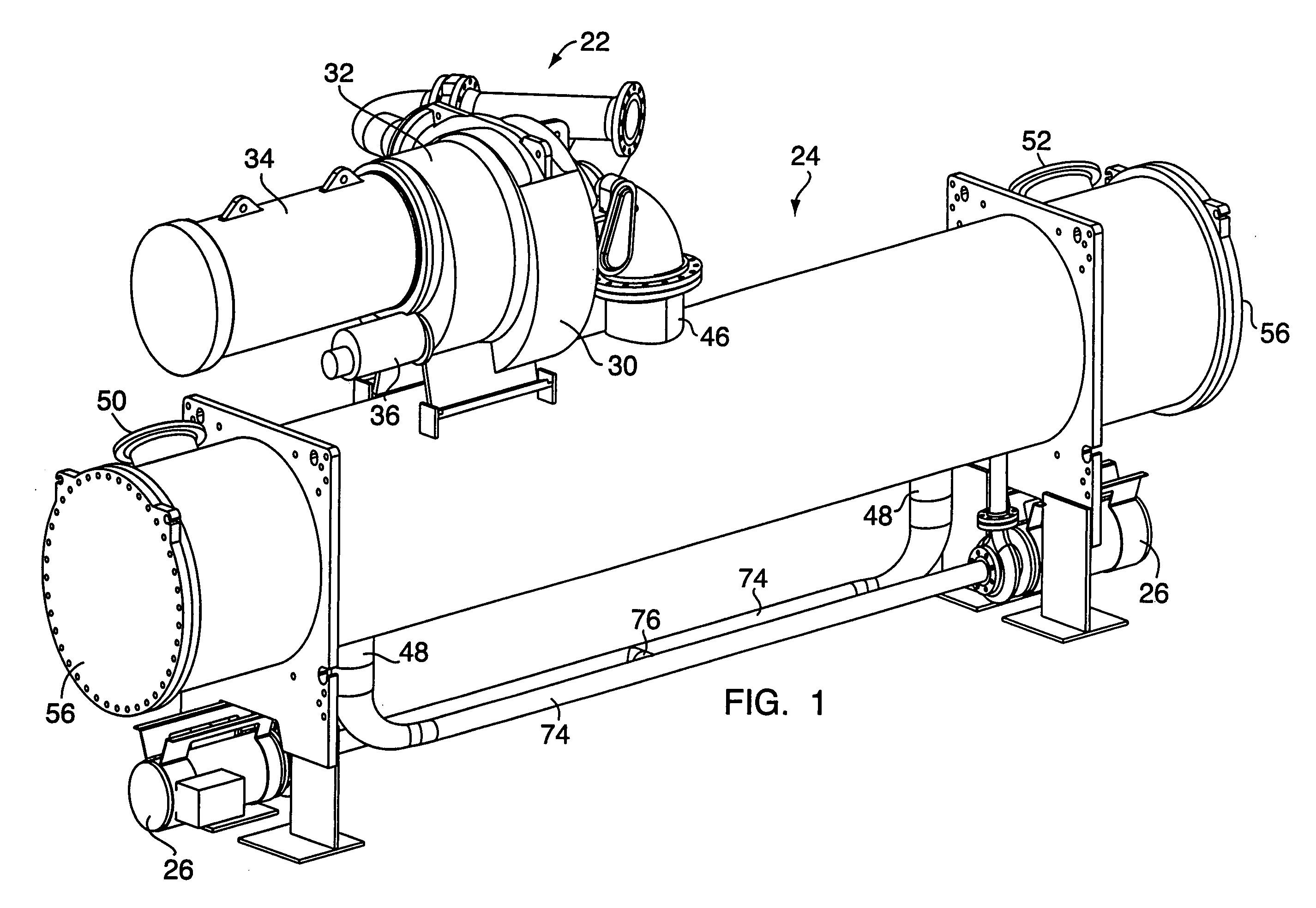

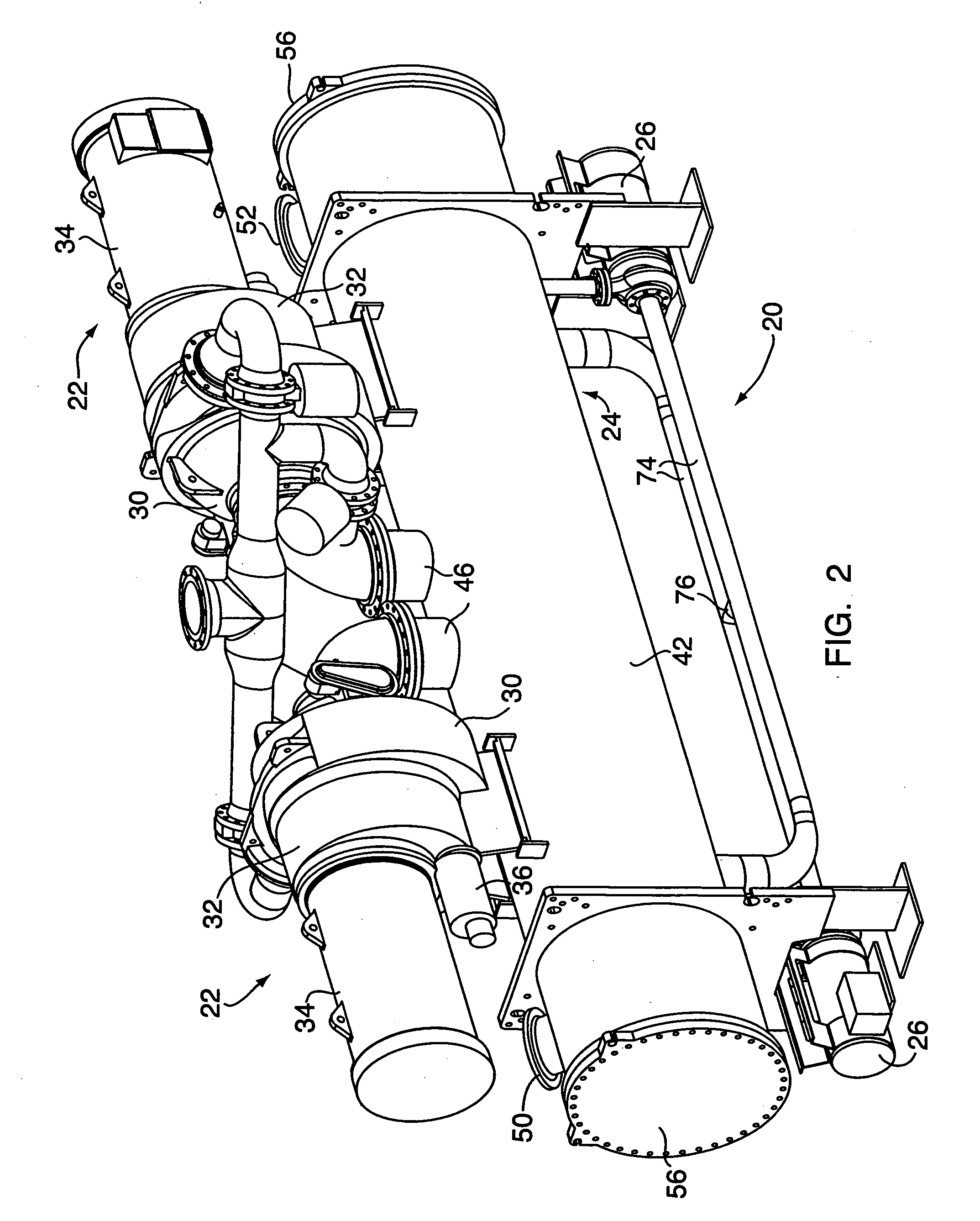

[0025] Referring to FIGS. 1-6, the present method for utilizing waste heat includes an organic Rankine cycle (ORC) device 20 for waste heat utilization. The ORC device 20 includes at least one of each of the following: 1) a turbine coupled with an electrical generator (together hereinafter referred to as the “turbo-generator 22”); 2) a condenser 24; 3) a refrigerant feed pump 26; 4) an evaporator 28; and 5) a control system. The ORC device 20 is preferably a closed “hermetic” system with no fluid makeup. In the event of leaks, either non-condensables are automatically purged from the device 20 or charge is manually replenished from refrigerant gas cylinders.

[0026] The ORC device 20 uses a commercially available refrigerant as the working medium. An example of an acceptable working medium is R-245fa (1,1,1,3,3, pentafluoropropane). R-245fa is a non-flammable, non-ozone depleting fluid. R-245fa has a saturation temperature near 300° F. and 300 PSIG that allows capture of waste heat o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com