Self-cleaning control method of cleaning equipment, cleaning equipment and storage medium

A technology for cleaning equipment and a control method, applied in the field of daily cleaning, can solve the problems of single self-cleaning mode and low flexibility, and achieve the effects of improving user experience, improving flexibility, and improving self-cleaning effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

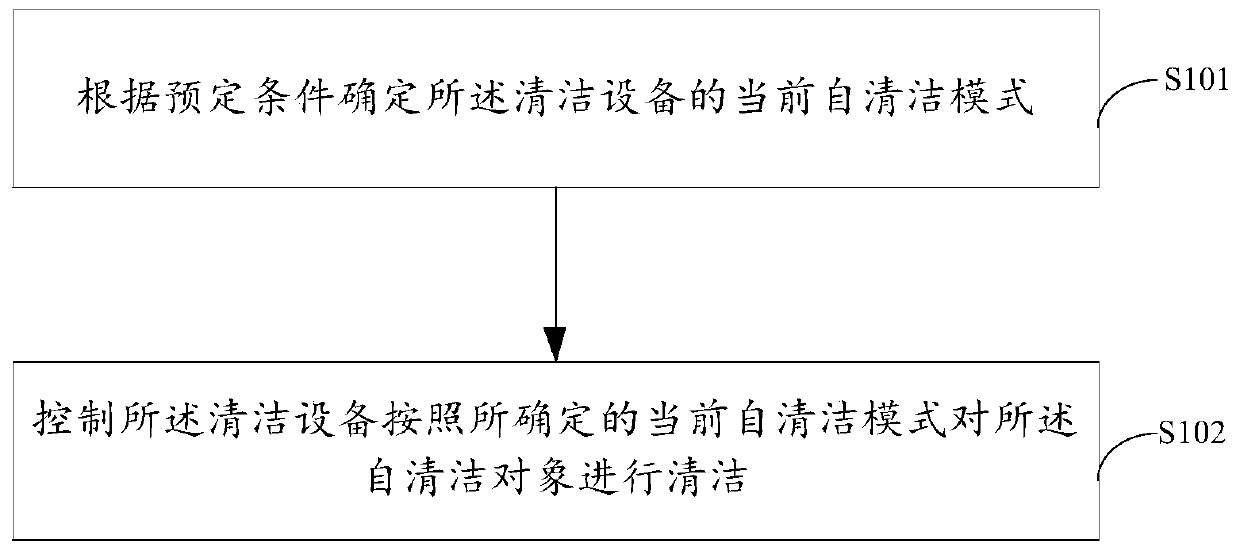

[0057] figure 1 For a schematic flow chart of the self-cleaning control method for cleaning equipment provided in Embodiment 1 of the present invention, please refer to figure 1 As shown, in the self-cleaning control method of the cleaning equipment provided by the embodiment of the present invention, the cleaning equipment has at least one self-cleaning object. An intelligent module, the control system can be placed entirely in the cleaning equipment, or some modules can be placed in the cleaning equipment, while other modules can be placed outside the cleaning equipment, and communicate with some modules of the control system in the cleaning equipment, for example, the control system It may include a control module placed in the cleaning device, a wireless communication module, and a terminal device placed outside the cleaning device for communicating with the wireless communication module.

[0058] This control method includes:

[0059] S101. Determine a current self-clea...

Embodiment 2

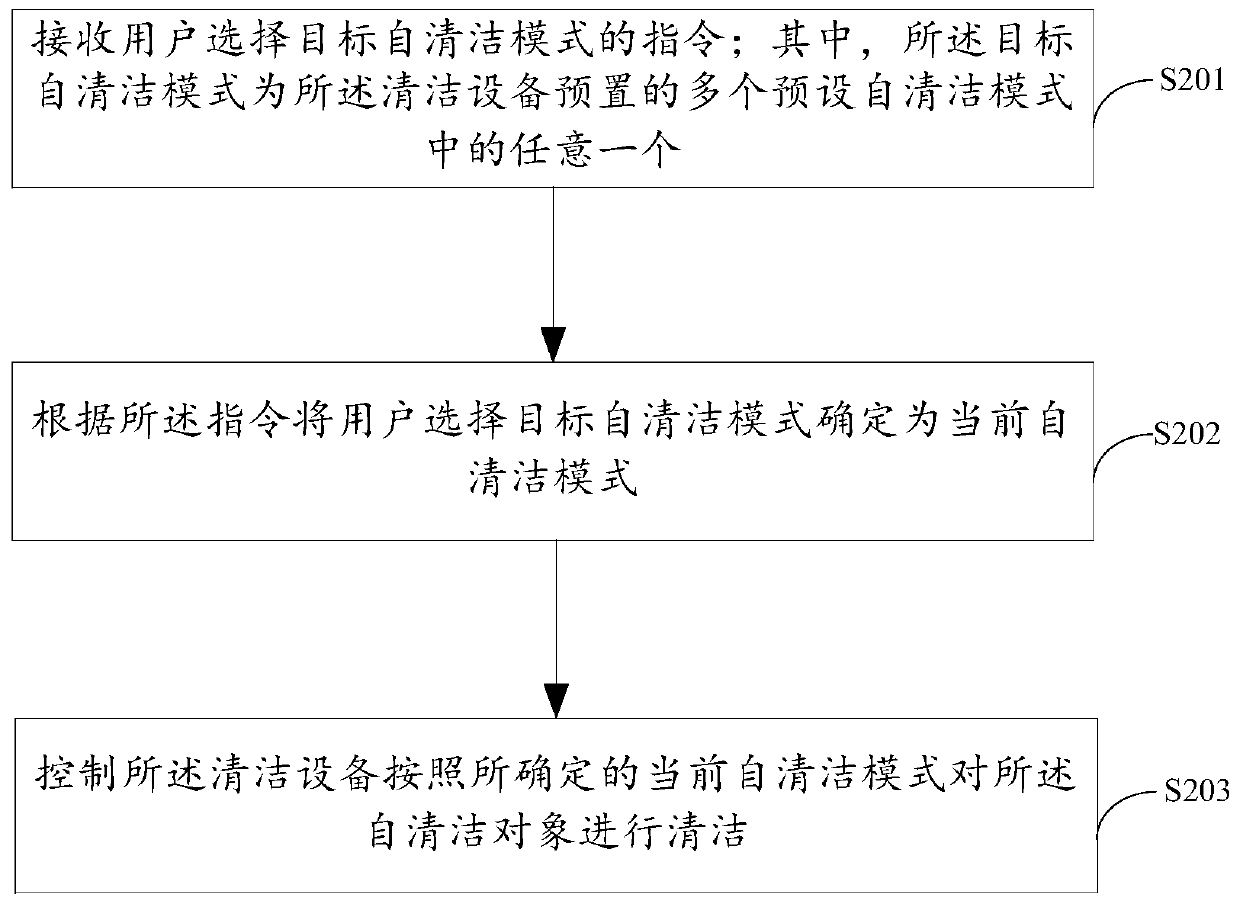

[0076] This embodiment provides a specific self-cleaning control method for cleaning equipment on the basis of the first embodiment. figure 2 A schematic flow chart of a self-cleaning control method for cleaning equipment provided in Embodiment 2 of the present invention; figure 2 As shown, the self-cleaning control method of the cleaning equipment provided in this embodiment includes:

[0077] S201. Receive an instruction from a user to select a target self-cleaning mode; wherein the target self-cleaning mode is any one of a plurality of preset self-cleaning modes preset by the cleaning device.

[0078] Programs corresponding to multiple working modes can be built into the cleaning device, such as fast cleaning mode, slow cleaning mode, heavy self-cleaning mode, mild self-cleaning mode, etc. For the heavy self-cleaning mode and the light self-cleaning mode, the two can distinguish the heavy self-cleaning mode and the light self-cleaning mode by the length of cleaning time,...

Embodiment 3

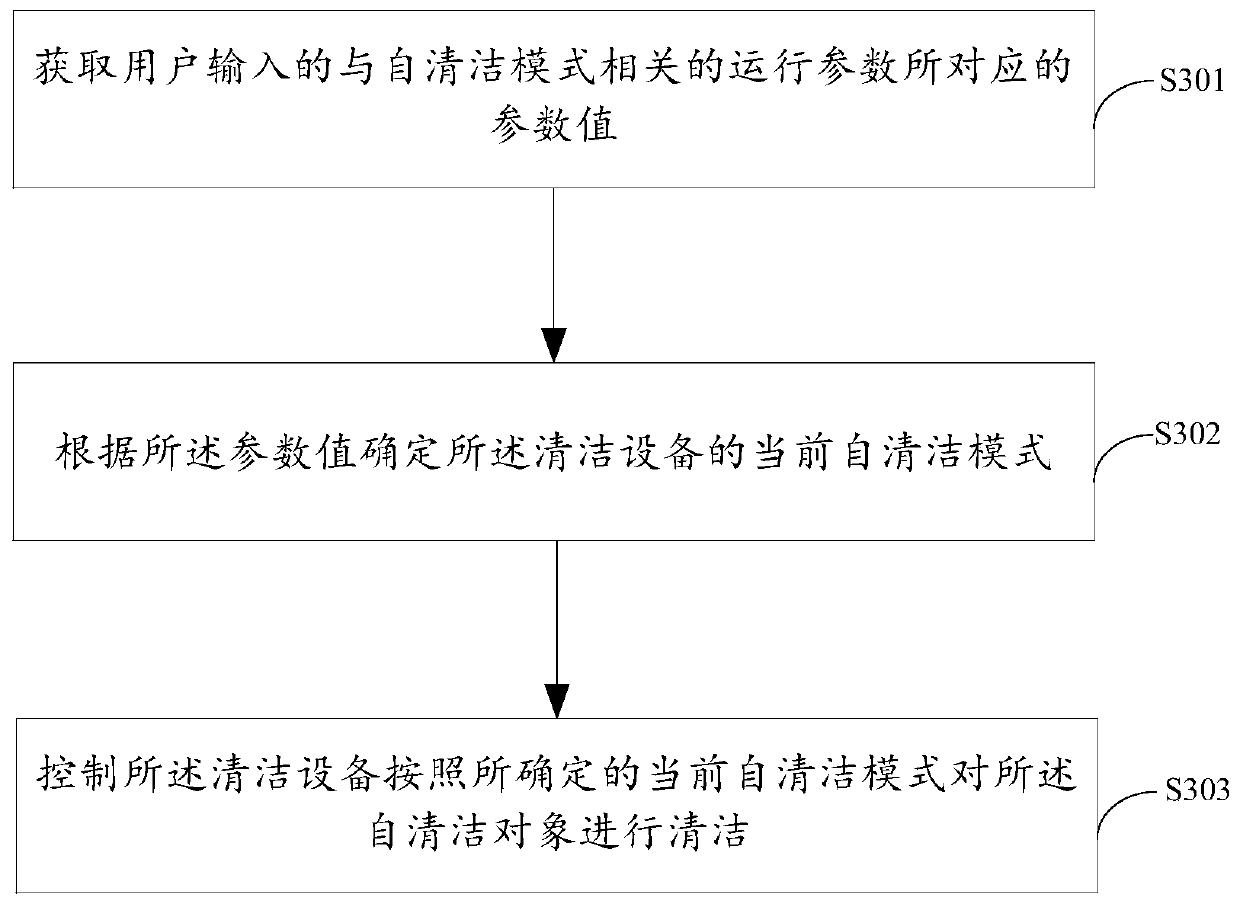

[0086] On the basis of the first embodiment, this embodiment provides a self-cleaning control method for cleaning equipment different from the second embodiment. image 3 A schematic flow chart of a self-cleaning control method for cleaning equipment provided in Embodiment 3 of the present invention; image 3 As shown, the self-cleaning control method of the cleaning equipment provided in this embodiment includes:

[0087] S301. Obtain parameter values corresponding to operating parameters related to the self-cleaning mode input by the user.

[0088] Specifically, an operating parameter setting area may be provided on the cleaning device, and the operating parameter setting area may be a display screen on the cleaning device, and the display screen may display a setting box for each operating parameter corresponding to the self-cleaning mode of the cleaning device , can also be a physical button or knob on the cleaning device, and the user can directly set the corresponding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com