PET-based graphene composite material, preparation method thereof, and aerostat

A composite material and graphene technology, applied in the direction of rigid spacecraft, etc., can solve the problems of poor dispersion of graphene oxide, and achieve the effects of improved dispersion, excellent gas barrier and mechanical strength, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

preparation example Construction

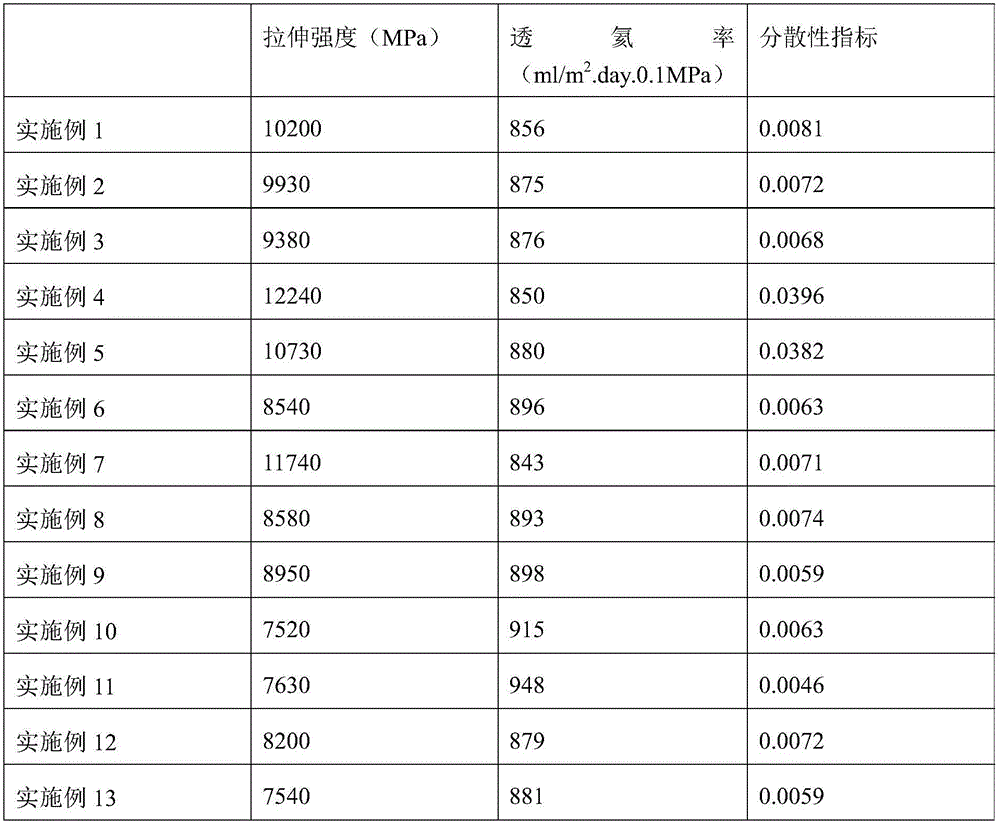

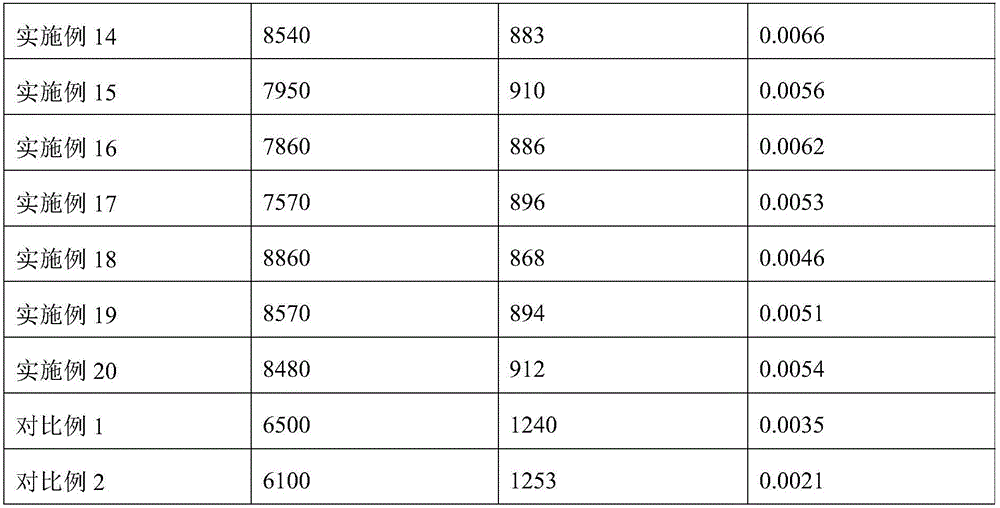

[0023] In order to solve the problem of poor dispersion of graphene oxide in the PET-based graphene composite material formed by the prior art melt blending method, in a typical implementation of the present application, a preparation of a PET-based graphene composite material is provided The method, the preparation method includes: step S1, the graphene oxide modified by ethylene glycol and the PET monomer are subjected to an esterification reaction or a transesterification reaction to obtain an initial product, and the PET monomer is terephthalic acid and / or terephthalic acid Dimethyl ester; Step S2, making the initial product undergo polycondensation reaction to obtain a PET-based graphene composite material.

[0024] The ethylene glycol-modified graphene oxide is in-situ polymerized with the PET monomer, and the graphene oxide is dispersed in it while the ethylene glycol is reacted with the PET monomer, thereby improving the composite of graphene on the PET-based graphene. ...

Embodiment 1

[0042] Take by weighing 5g polyvinylpyrrolidone (PVP) and add in the ethylene glycol of 600ml and stir at room temperature until completely dissolving to form ethylene glycol solution; Add 5g graphene oxide powder in this ethylene glycol solution, the exfoliation of this graphene oxide powder The thickness is 3nm, the length is 50μm, and the colloidal solution of ethylene glycol-modified graphene oxide is obtained by ultrasonic treatment with a power of 500W for 2 hours; the prepared graphite oxide is added to a 5L polymerization kettle with nitrogen gas inlet and outlet and mechanical stirring Ethylene glycol colloid solution and 1000g of terephthalic acid (PTA) (wherein the molar ratio of ethylene glycol to terephthalic acid is 1.5:1), 0.3gSb 2 o 3 , start mechanical stirring, and replace the air in the polymerization kettle with high-purity nitrogen at the same time, replace it 4 times, make the pressure in the polymerization kettle 0.2MPa, raise the temperature of the poly...

Embodiment 2

[0044] Take by weighing 5g polyvinylpyrrolidone (PVP) and add in the ethylene glycol of 600ml and stir at room temperature until completely dissolving to form ethylene glycol solution; Add 5g graphene oxide powder in this ethylene glycol solution, the exfoliation of this graphene oxide powder The thickness is 3nm, the length is 50μm, and the colloidal solution of ethylene glycol-modified graphene oxide is obtained by ultrasonic treatment with a power of 500W for 2 hours; the prepared graphite oxide is added to a 5L polymerization kettle with nitrogen gas inlet and outlet and mechanical stirring Ethylene glycol colloid solution and 1000g of terephthalic acid (PTA) (wherein the molar ratio of ethylene glycol to terephthalic acid is 1.5:1), 0.3gSb 2 o 3 , start mechanical stirring, and replace the air in the polymerization kettle with high-purity nitrogen at the same time, replace it 4 times, make the pressure in the polymerization kettle 0.4MPa, raise the temperature of the poly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com