Preparation of wire coated paint of polyester paint and polyester imine paint by using terephthalic acid

A technology of polyester wire enamel and terephthalic acid, which is applied in the field of polyesterimide wire enamel and polyester production, and can solve the problems of easy sublimation of dimethyl terephthalate, blockage of condensers, and large environmental pollution. To achieve the effect of easy control of the process, increase of line speed and uniform molecular weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

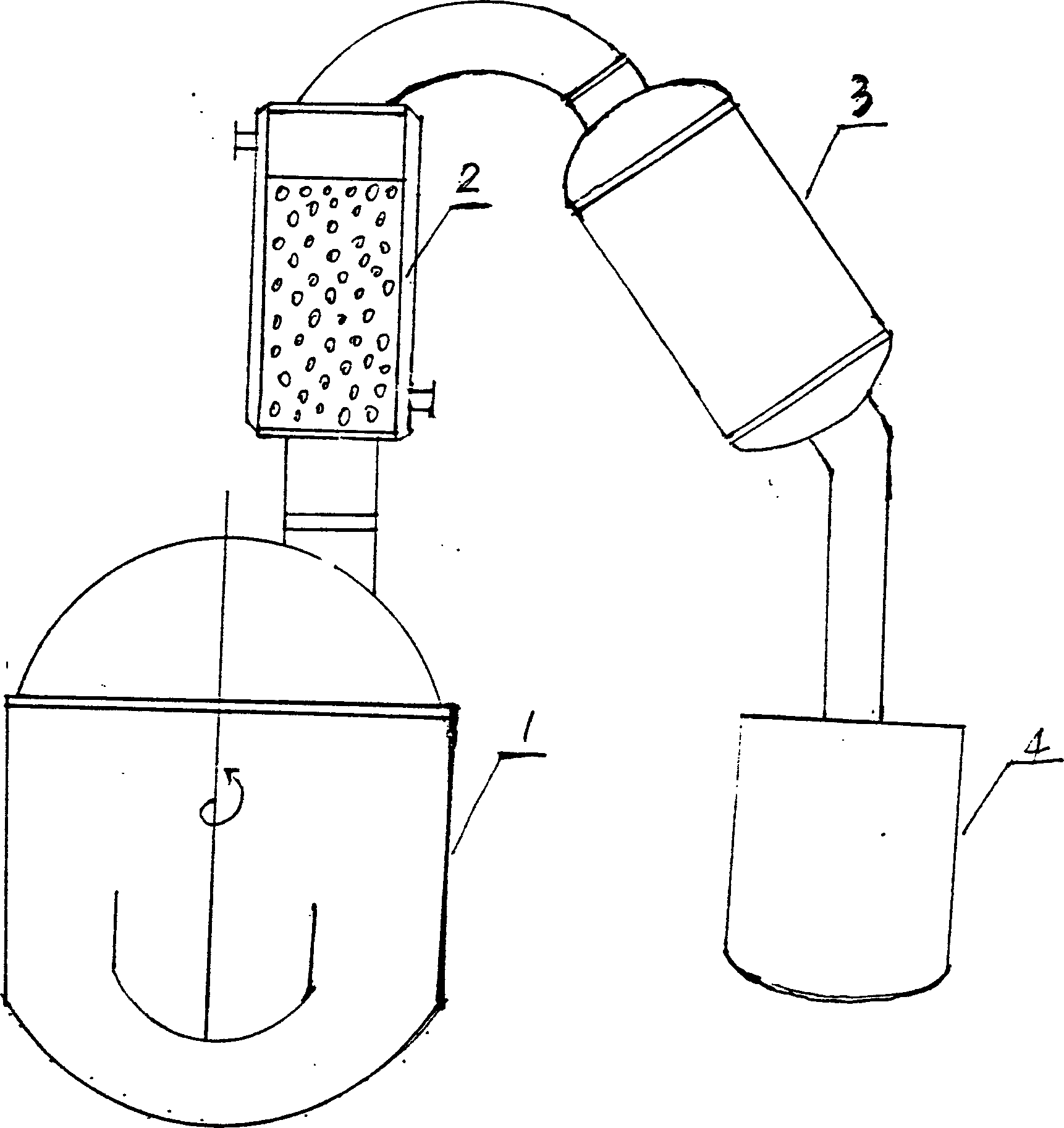

Image

Examples

Embodiment Construction

[0019] Weigh 260 kg of terephthalic acid, 100 kg of ethylene glycol, and 90 kg of glycerin, put them into a 1000-liter oil-heated stainless steel reactor, add 0.02 kg each of zinc acetate and catalyst Pt, and heat up to 200-220 °C, strictly Control the outlet temperature of the fractionation column between 110-115°C. Stir and react stably for 8-10 hours. After esterification, keep warm at 220°C, carry out vacuum polycondensation reaction, release the vacuum after reaching the required viscosity, add 400 kg of cresol, dissolve evenly, and cool down to below 100°C , add 280 kg of xylene to dilute, and at the same time add 15 kg of butyl orthotitanate and 3-5 kg of leveling agent, and mix well.

[0020] The production of polyesterimide wire enamel is to cool down to 140°C after esterification, add 68 kg of trimellitic anhydride and 47 kg of 4,4'-diaminodiphenyl ether, gradually raise the temperature to 180°C, and react for 1 hour Afterwards, the temperature was raised to 220° ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com