Process for high and medium energy dye printing a flocked article

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

The Process and Article of the First Embodiment

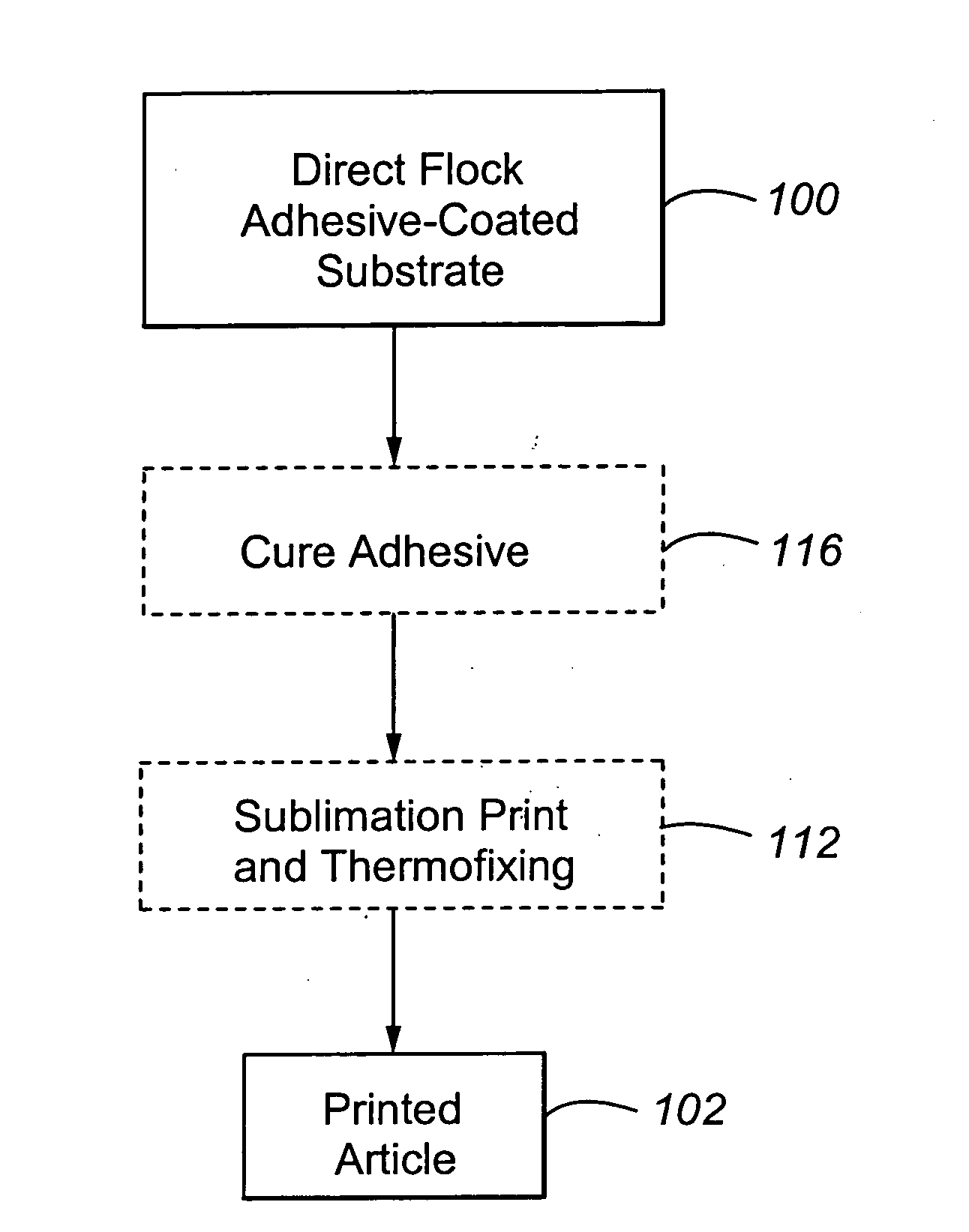

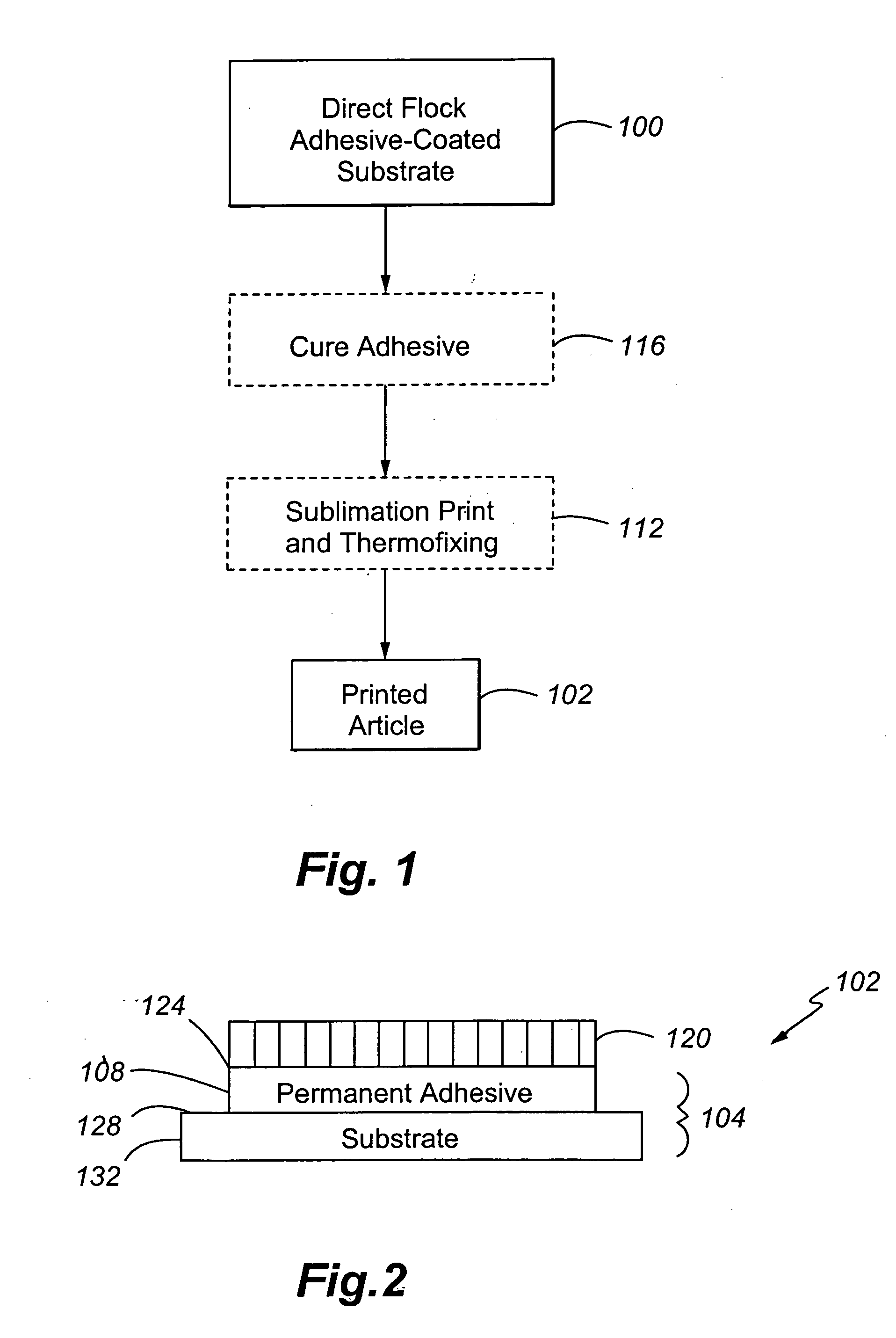

[0066] Referring to FIGS. 1 and 2, the process and article of the first embodiment of the present invention will now be described.

[0067] In the first step 100, the adhesive-coated substrate 104 is direct flocked by known techniques using the flock of the present invention. The PCT-containing flock is typically white in color or contains little pigment and can be flocked by any suitable technique, with electrostatic flocking being preferred. The adhesive may be applied discontinuously to the substrate in a desired (direct) image.

[0068] The adhesive used in adhesive layer 108 may be any suitable permanent adhesive (as opposed to a release adhesive) that is thermally compatible with the sublimation ink printing temperature used in step 112. “Thermal compatibility” depends on the process configuration. When the adhesive is cured (e.g., fully activated, set, cross-linked, fused, otherwise fully bonded) 116 before sublimation ink printing i...

second embodiment

The Process and Article of the Second Embodiment

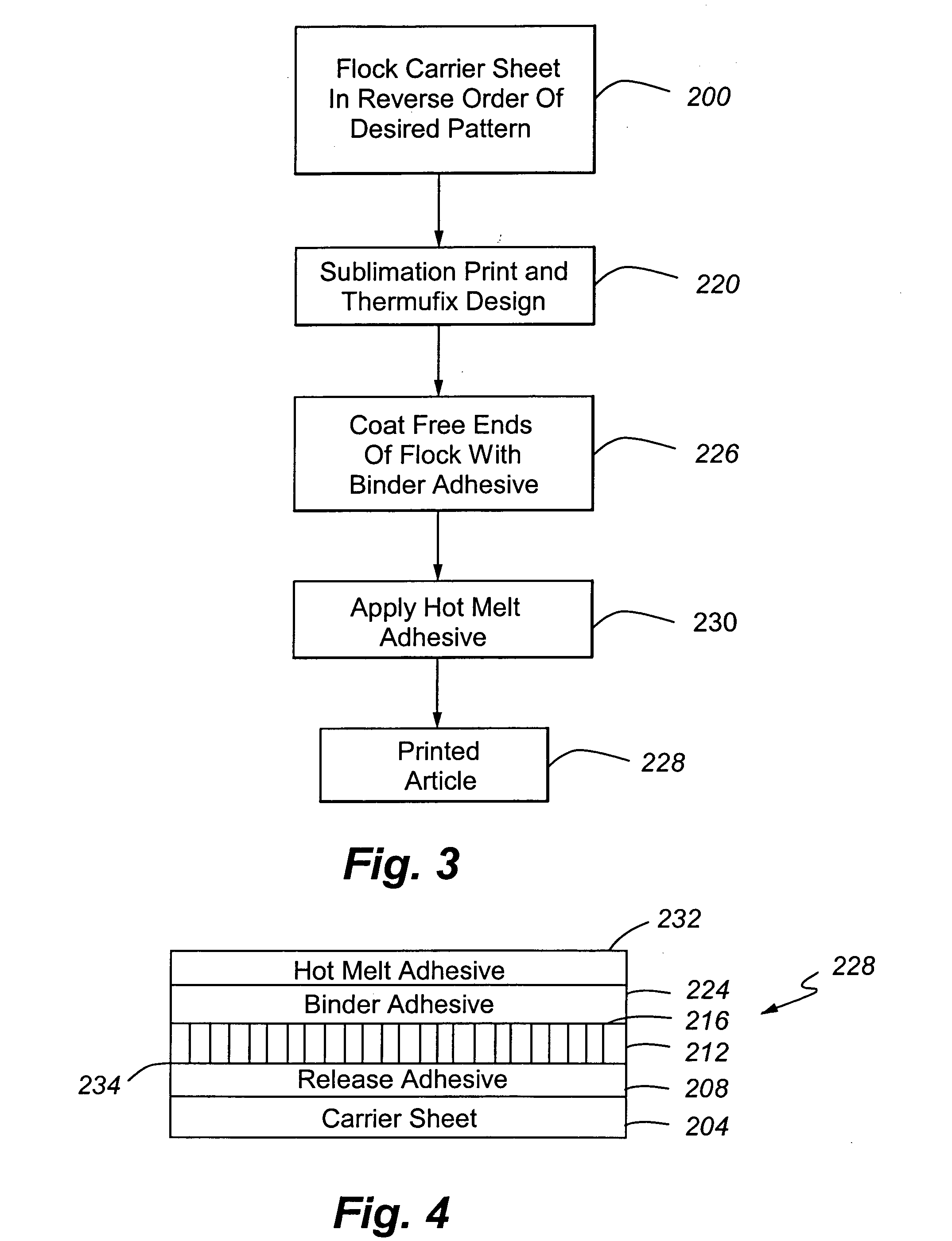

[0076] Referring to FIGS. 3 and 4, the process and article of the second embodiment of the present invention will now be described.

[0077] In step 200, the carrier sheet 204 containing a temporary release adhesive 208 (such as wax) in the reverse of the desired pattern or image is flocked by suitable techniques, preferably electrostatically, with the flock of the present invention. The carrier locates temporarily the flock fibers and then hold flock fibers in the desired position for subsequent processing.

[0078] The carrier sheet 204 can be any suitable transfer carrier, such as dimensionally stable paper, processed paper, plastic film, resin sheets, and metal foils. Depending on the desired effect and the sheet materials employed, the carrier can be transparent, translucent, or opaque, but is typically transparent. Typically (but not always), the primary carrier is a discontinuous sheet as opposed to a continuous sheet on a running w...

third embodiment

The Process and Article of the Third Embodiment

[0090] Referring to FIGS. 7-10, a third process embodiment will now be described.

[0091] In step 700, the sublimation ink is printed onto the carrier 804 by known techniques, such as lithography, letterpress, gravure, flexography, screen printing, and jet printing. As can be seen in FIG. 8, the sublimation ink 808 is positioned on top of the release adhesive 812 and carrier sheet 816. Both the sublimation ink 808 and release adhesive 812 are printed on the carrier sheet 816 in the reverse of the desired pattern / design.

[0092] The preferred release adhesive is preferably a pressure-sensitive and soft film adhesive (such as an acrylic adhesive) and a hot melt adhesive (such as a compounded block rubber adhesive and a silicon rubber adhesive). Silicon release adhesives can withstand thermofixing temperatures if used properly. Acrylic and silicon release adhesives are applied to the carrier sheet 816 and cured before using them to hold the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com