Multi-layer fabric and preparation method thereof

A manufacturing method and fabric technology, applied in textiles and papermaking, weft knitting, knitting, etc., can solve the problem of fabric bulkiness that needs to be further improved, and achieve strong bulkiness, tight and flat stitches, and maintain bulkiness and stiffness. sense of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below through specific embodiments in conjunction with the accompanying drawings.

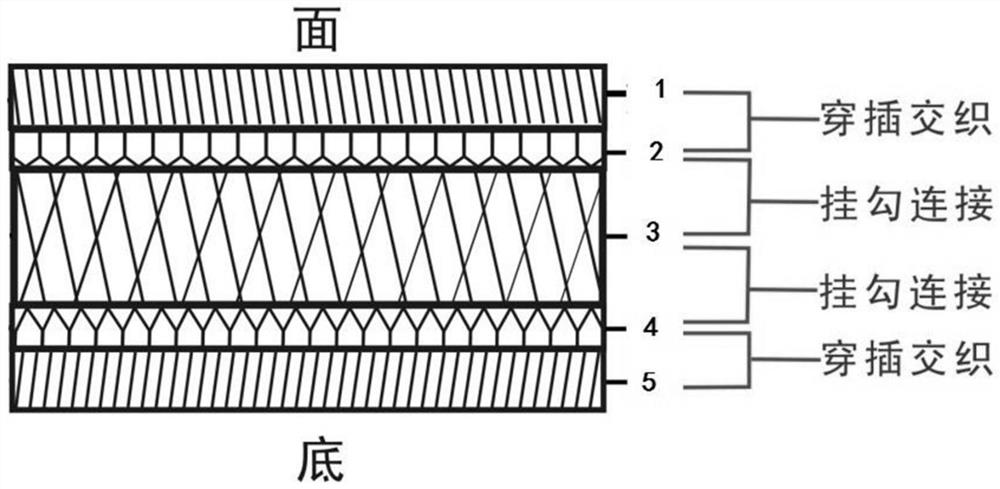

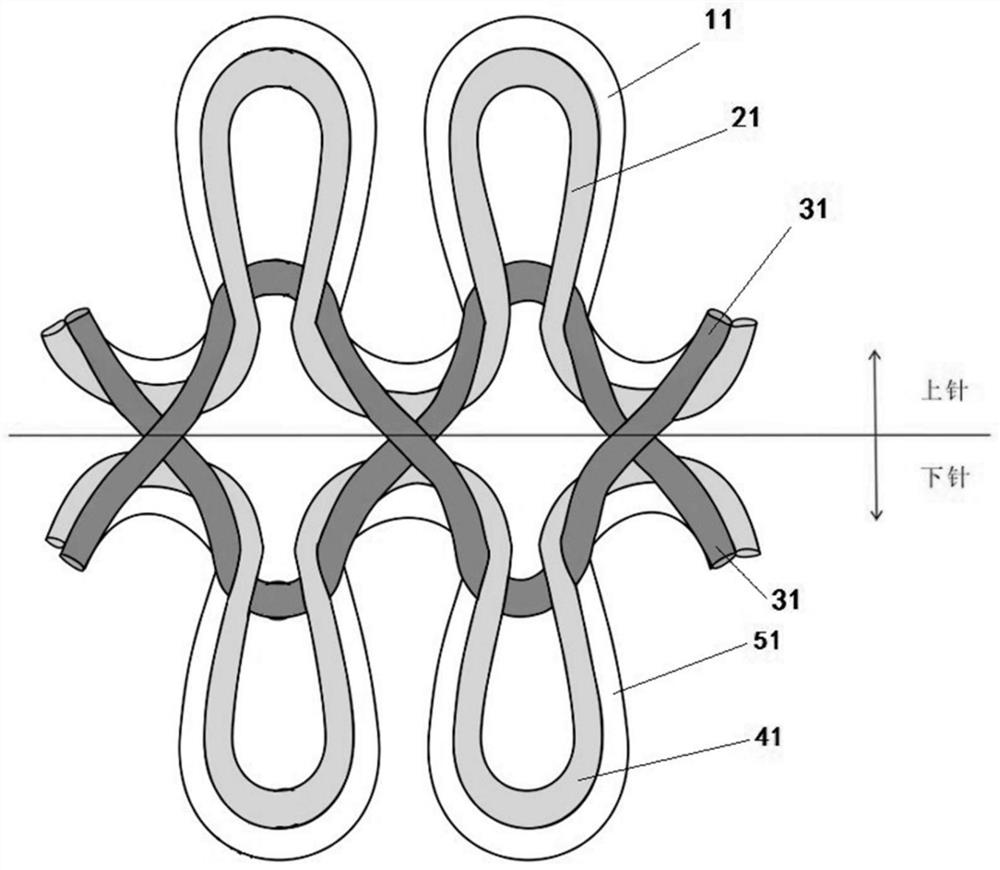

[0026] Embodiments of the present invention provide a multi-layer fabric, such as Figure 1-2 As shown, it includes the first cotton surface layer 1, the first polyester interlayer 2, the polyester inner layer 3, the second polyester interlayer 4 and the second cotton surface layer 5 arranged in sequence along the thickness direction of the fabric, the first cotton surface layer 1 and the second cotton surface layer 5 are all composed of cotton, and the first polyester interlayer 2, the polyester inner layer 3 and the second polyester interlayer 4 are all composed of polyester. The polyester inner layer 3 is woven by two groups of first polyester filaments 11 interwoven with each other, and the two groups of first polyester filaments 31 are respectively connected with the first polyester interlayer 2 and the second polyester inter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average thickness | aaaaa | aaaaa |

| Yarn length | aaaaa | aaaaa |

| Yarn length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com