Weaving integration based silk quilt gauze fabric

A silk quilt and fabric technology, applied in the field of textile fabrics, can solve the problems of low bulkiness of silk quilt fabrics, low fabric utilization rate, large manufacturing raw materials, etc., and achieve the effects of saving labor costs and resources, soft hand feeling, and reducing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

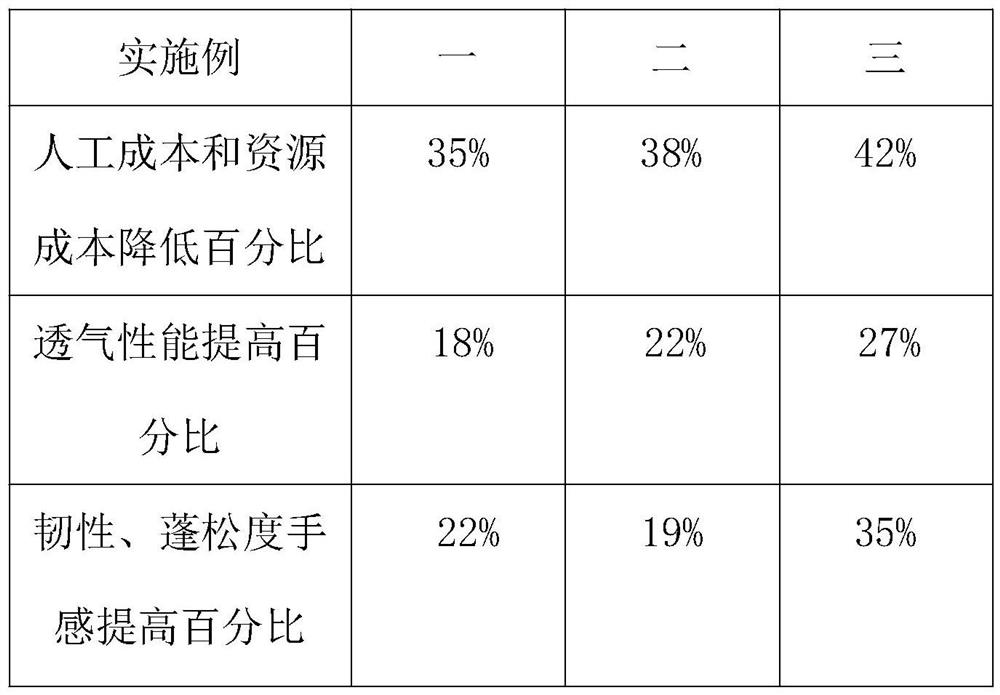

Embodiment 1

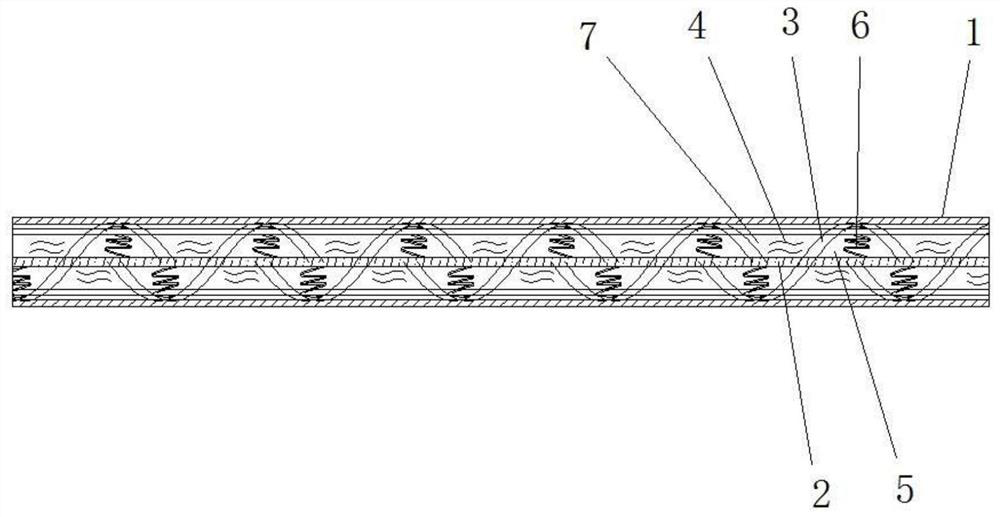

[0026] refer to Figure 1-2 In this embodiment, a weaving integrated silk quilt gauze fabric is proposed, including a silk quilt gauze fabric body, and the silk quilt gauze fabric body includes a fabric inner base layer 2 and a fabric outer covering above and below the fabric inner base layer 2 Layer 1, the outer covering layer 1 of the fabric and the inner base layer 2 of the fabric are woven with spirally wound silk threads 3, and the spirally wound silk threads 3 alternately penetrate through the inner base layer 2 of the fabric in a spiral wave structure;

[0027] A first gap 5 is formed between the inner side of the arched part of the spirally wound silk thread 3 and the lining base layer 2 of the fabric, and the stretch yarn arranged horizontally is woven between the lining base layer 2 of the fabric located in the first gap 5 and the spirally wound silk thread 3 6. A second gap 7 is formed between two adjacent helically wound wires 3, the second gap 7 is braided with ho...

Embodiment 2

[0039] The difference between this example and the above example 1 is as follows:

[0040] Further in this example, the weight ratio of the fabric outer cover layer 1 to the fabric inner base layer 2 is 1:0.8-0.9.

[0041] Further in this example, the warp density of the inner base layer 2 of the fabric is 117-125 threads / cm, and the weft density of the inner base layer 2 of the fabric is 58-65 threads / cm; the inner base layer 2 of the fabric comprises the following percentages Raw materials: mulberry silk 60-75%, rayon 22-32%, cotton fiber silk 10-13%.

[0042]Further in this example, the warp density of the inner base layer 2 of the fabric is 117 threads / cm, and the weft density of the inner base layer 2 of the fabric is 58 threads / cm; the inner base layer 2 of the fabric comprises the following percentages of raw materials: silk 68. Rayon 22%, cotton fiber silk 10%.

[0043] Further in this example, the warp density of the fabric outer cover 1 is 123-130 threads / cm, and t...

Embodiment 3

[0046] The difference in this example compared with the above two examples 1 and 2 is as follows:

[0047] In this example, the weight ratio of the fabric outer cover layer 1 to the fabric inner base layer 2 is 1:0.8-0.85.

[0048] In this example, the warp density of the base layer 2 in the fabric is 120 threads / cm, and the weft density of the base layer 2 in the fabric is 60 threads / cm; the base layer 2 in the fabric includes the raw materials of the following percentages: mulberry silk 65, 25% rayon, 10% cotton fiber.

[0049] In this example, the warp density of the outer covering layer 1 of the fabric is 130 threads / cm, and the weft density of the outer covering layer 1 of the fabric is 60 threads / cm; the outer covering layer 1 of the fabric comprises the raw materials of the following percentages: Yarn 63%, natural rain linen 10%, cotton fiber 12%, tencel 10%, goose down 5%.

[0050] As we all know, natural rain linen has the characteristics of sweat absorption, good a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com