Flame-retardant composite fabric and preparation method thereof

A flame-retardant composite and fabric technology, which is applied in the field of flame-retardant materials, can solve problems that affect human health, are prone to explosions, and skin rot, and achieve high flame retardancy, improved flame retardancy, and improved flame retardancy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

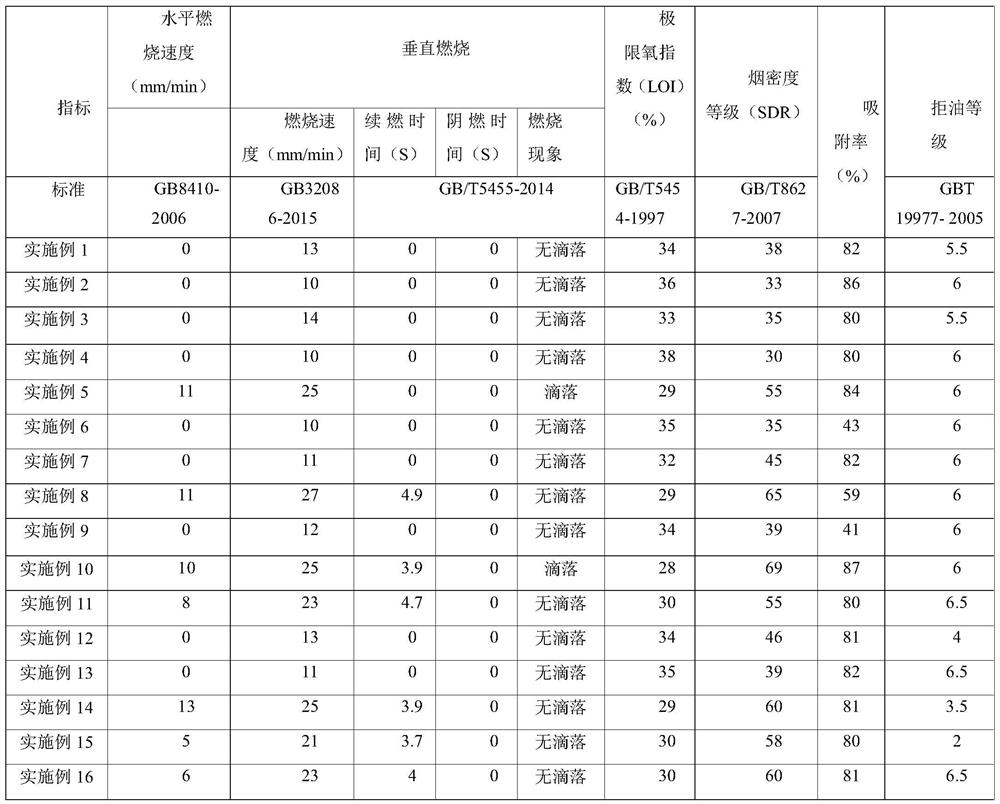

Examples

Embodiment 1

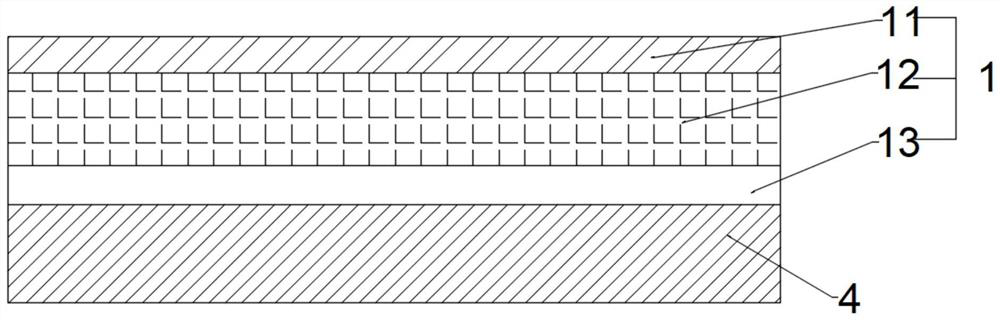

[0030] S1 in parts by weight, the inner layer fabric 4 is obtained after twisting and blending the pure cotton of 30 parts of aramid fiber 1313, 30 parts and 50 parts of activated carbon fibers, and the yarn fineness of the inner layer fabric 4 is 60tex; After 30 parts of basalt fibers and 30 parts of cotton fibers and 30 parts of polytetrafluoroethylene fibers are blended, the blended textile layer 12 is made, and the yarn fineness of the blended textile layer 12 is 60tex; the inner layer fabric 4 and the blended textile The weight of 12 layers is 150g / m 2 ;

[0031] S2 coats one side of the blended textile layer 12 with an airgel heat insulating coating 13, and the other side is coated with a flame retardant heat insulating coating 11; the thickness of the airgel heat insulating coating 13 and the flame retardant heat insulating coating 11 Both are 0.35mm;

[0032] The steps of applying the airgel thermal insulation coating 13 include:

[0033] S211 In parts by weight, full...

Embodiment 2

[0040] S1 in parts by weight, the inner layer fabric 4 is obtained after twisting and blending 40 parts of aramid fiber 1313, 20 parts of pure cotton and 40 parts of activated carbon fibers, and the yarn fineness of the inner layer fabric 4 is 60tex; In parts by weight, after blending 40 parts of basalt fiber and 20 parts of cotton fiber and 40 parts of polytetrafluoroethylene fiber, the blended textile layer 12 is made, and the yarn fineness of the blended textile layer 12 is 60tex; the inner layer fabric 4 And described blended fabric layer 12 gram weights are all 150g / m 2 ;

[0041] S2 coats one side of the blended textile layer 12 with an airgel heat insulating coating 13, and the other side is coated with a flame retardant heat insulating coating 11; the thickness of the airgel heat insulating coating 13 and the flame retardant heat insulating coating 11 Both are 0.35mm; the step of coating airgel thermal insulation coating 13 comprises:

[0042] S211 In parts by weight...

Embodiment 3

[0049] S1 in parts by weight, the inner layer fabric 4 is obtained after twisting and blending the pure cotton of 35 parts of aramid fiber 1313, 25 parts and 45 parts of activated carbon fibers, and the yarn fineness of the inner layer fabric 4 is 60tex; After 35 parts of basalt fibers and 25 parts of cotton fibers and 35 parts of polytetrafluoroethylene fibers are blended, the blended textile layer 12 is made, and the yarn fineness of the blended textile layer 12 is 60tex; the inner layer fabric 4 and the blended textile The weight of 12 layers is 150g / m 2 ;

[0050] S2 coats one side of the blended textile layer 12 with an airgel heat insulating coating 13, and the other side is coated with a flame retardant heat insulating coating 11; the thickness of the airgel heat insulating coating 13 and the flame retardant heat insulating coating 11 Both are 0.35mm;

[0051] The steps of applying the airgel thermal insulation coating 13 include:

[0052] S211 In parts by weight, fu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com